Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

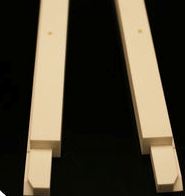

Overview of Isostatic Pressing Sintering Polish Alumina Ceramic bar Rod 555

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Isostatic Pressing Sintering Polish Alumina Ceramic bar Rod 555

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Isostatic Pressing Sintering Polish Alumina Ceramic bar Rod 555

This alumina ceramic bar measures 5mm in diameter and 55mm long. It is made from high pureness alumina powder. The powder obtains pressed utilizing isostatic pushing. This approach uses equivalent stress from all sides. It creates a very dense and consistent green body. Next, the eco-friendly body goes through high temperature sintering. Sintering bonds the bits together completely. This forms a solid ceramic structure. The last action is accuracy polishing. Sprucing up gives bench a smooth, great surface area coating. This coating minimizes rubbing. It likewise boosts wear resistance.

The material is exceptionally tough. It is much harder than steel. This firmness supplies wonderful resistance to abrasion. The bar withstands severe wear. It lasts long in difficult problems. Alumina ceramic takes care of very heats. It functions reliably up to 1600 ° C. It maintains its strength and shape. Thermal shock resistance is good. It takes care of fast temperature level modifications well. Bench is a superb electrical insulator. It has high dielectric strength. This is essential in electrical applications. Chemical resistance is one more essential feature. It stands up to attack from acids and antacids. It performs well in harsh environments. The material won’t rust or corrosion.

This ceramic bar is non-porous. Its thickness is extremely high. Isostatic pushing ensures this. The framework is consistent throughout. There are no weak spots. The sleek surface reduces particle generation. This is vital in clean processes. The dimensions are precise. They fulfill tight tolerances. This bar suits many demanding applications. It functions well for precision fixtures. It acts as wear-resistant overviews. It operates as protecting parts. It is used in furnace components. It discovers duties in semiconductor tools. It is common in medical gadgets. It manages high voltage situations. Its resilience and security are proven.

Applications of Isostatic Pressing Sintering Polish Alumina Ceramic bar Rod 555

Isostatic pushing produces superior alumina ceramic bars. This method applies equal stress from all directions. It compacts alumina powder extremely uniformly. The result is a thick, regular framework throughout the product. This is important for high-performance porcelains. Alumina purity is commonly 95% or higher. This guarantees superb buildings. The material is really strong and durable. It manages severe temperatures quickly. Alumina ceramic stands up to wear extremely well. It takes on severe chemicals. Electric insulation is another key advantage.

The certain item is a polished bar pole gauging 5mm by 55mm. Accurate measurements are guaranteed. The surface area finish is polished smooth. This polishing reduces friction considerably. It decreases fragment dropping. A smooth surface area is essential for several applications. It makes sure better securing where required. It protects against contamination in sensitive procedures.

These bars are incredibly functional. They are best for high-temperature furnace components. Believe thermocouple protection tubes. Think about heating system liners and sustains. They serve well in semiconductor production equipment. Wafer handling parts gain from their buildings. They are perfect for plasma etching components. Research laboratory devices utilizes them extensively. Crucibles and sample owners prevail instances. They work accurately in chemical processing plants. Pump seals and valve components are normal usages. They execute in electrical insulators. High-voltage applications demand their security. They are located in laser systems as well. Mounting hardware and aperture components utilize them.

The manufacturing process makes sure very little internal imperfections. This brings about foreseeable mechanical stamina. Thermal shock resistance is improved. The polished coating provides ready-to-use surfaces. It saves machining time for end users. Quality assurance is strict. Every bar satisfies precise specs. This ensures efficiency and dependability sought after settings.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Isostatic Pressing Sintering Polish Alumina Ceramic bar Rod 555

What makes isostatic pressing better for these bars?

Isostatic pressing applies equal pressure from all sides. This makes the ceramic much denser and more uniform. It reduces weak spots inside the material. This gives better strength and reliability.

How precise are the 555mm dimensions?

We control the dimensions very tightly. The diameter is 5mm ±0.05mm. The length is 55mm ±0.1mm. This high precision is good for fitting into assemblies. It ensures consistent performance.

Can this alumina ceramic handle high heat?

Yes, it handles extreme heat very well. Its maximum working temperature is 1600°C. It keeps its strength and shape at high temperatures. It resists thermal shock well too. This makes it suitable for furnace parts and hot environments.

What polish level is available?

We offer two main polish finishes. You can get a smooth surface finish. You can also get a mirror polish finish. The smooth finish has a roughness (Ra) around 0.2μm. The mirror finish is much finer, below 0.05μm Ra. The polish reduces friction and wear.

Where are these bars typically used?

These bars work well in demanding jobs. Common uses include high-temperature furnace fixtures. They serve as precision guides and shafts. They are used in semiconductor processing equipment. They work in wear-resistant parts and electrical insulators. Their stability and hardness are key advantages.

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

6mm 8mm 10mm Diameter Aluminum Round bar 6063

High Purity Wear Resistance 99.5% Alumina Al2o3 Ceramic Rod Bar Stick

Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Customized ZTA Al2O3 Alumina ZrO2 Zirconia Ceramic square Rod bar