Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

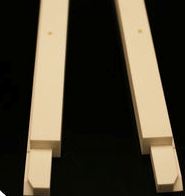

Overview of Mirror Polished 95% 99% Alumina Al2o3 Ceramic bar Guide for Textile Machinery

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Mirror Polished 95% 99% Alumina Al2o3 Ceramic bar Guide for Textile Machinery

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Mirror Polished 95% 99% Alumina Al2o3 Ceramic bar Guide for Textile Machinery

Mirror polished alumina ceramic bars direct fabric threads smoothly. They are available in 2 pureness degrees, 95% and 99% Al2O3. Select based on your requirements. Higher purity indicates better efficiency.

The 99% grade supplies premium solidity. It stands up to wear remarkably well. This decreases thread breaks and snags. It maintains fiber top quality high. The 99% quality manages extreme friction. It operates in high-speed textile equipments. It tolerates extreme warmth. This quality lasts much longer than steel overviews. It reduces downtime for substitutes.

The 95% quality gives great performance. It sets you back less than the 99%. It is still extremely hard and durable. It resists abrasion efficiently. This grade matches many standard fabric applications well. It provides a solid worth.

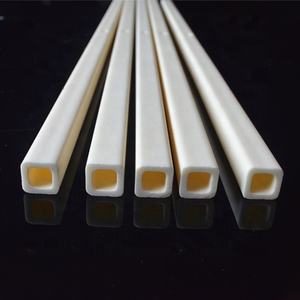

Both grades feature a mirror polish finish. This surface is extremely smooth. Ra worths are really reduced. The gloss reduces rubbing substantially. Threads glide easily over the ceramic. It stops fiber damages. It stops static build-up. The guides remain clean longer.

Criterion dimensions include diameters like 6mm, 8mm, 10mm, 12mm. Lengths are 100mm, 150mm, 200mm, 300mm. Various other measurements are possible. Request custom dimensions if needed.

These ceramic overviews withstand chemicals. They withstand acids, antacid, solvents. Textile dyes and cleaners won’t harm them. They are untouched by wetness. Rust is difficult. They run dependably in wet problems.

Installment is straightforward. Mount them safely in your equipment frames. Their fundamental security prevents bending. They require virtually no upkeep. Merely clean them tidy periodically. They conserve considerable operating expense in time.

Applications of Mirror Polished 95% 99% Alumina Al2o3 Ceramic bar Guide for Textile Machinery

Mirror brightened alumina ceramic bars are vital for fabric devices. They direct yarns and fibers with manufacturing. These bars are made from high purity alumina. 2 qualities prevail, 95% and 99% Al2O3. The mirror finish is essential. It creates an incredibly smooth surface. Fibers slide quickly over this surface area. Rubbing is considerably decreased.

Much less rubbing suggests much less fiber damages. Broken strings occur less usually. This improves yarn top quality. It additionally decreases maker quits. Production runs smoother. The ceramic product is exceptionally tough. It resists wear better than metal overviews. Metal overviews use down. They obtain grooves and scrapes. These flaws snag fibers. Ceramic guides remain smooth for a long period of time. This implies less replacement. It conserves money and downtime.

Alumina ceramic is also chemically inert. It overlooks wetness, oils, and chemicals made use of in textile processing. Steel overviews can wear away or react. This creates rough places. Ceramic remains accurately smooth. The high pureness alumina withstands warmth well. It functions penalty in warm equipment environments. Fabric equipments run much faster with these guides. The smooth surface area allows higher rates without extra fiber breaks. Fabric high quality is more constant. Device parts last longer also. Much less rubbing implies much less endure various other elements.

Making use of these ceramic bars is simple. They fit into existing overview settings. They require very little maintenance. Just maintain them tidy. No special treatments are required. The outcome is trustworthy, top quality textile manufacturing.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Mirror Polished 95% 99% Alumina Al2o3 Ceramic bar Guide for Textile Machinery

What are these alumina ceramic bars for?

They guide yarns and threads in textile machines. The bars prevent abrasion. They keep fibers moving smoothly. This reduces breaks and defects. Machines run better with them.

What’s the difference between 95% and 99% alumina?

99% alumina is harder. It resists wear better. It handles very high speeds well. 99% alumina costs more. 95% alumina is very tough too. It works great for most textile jobs. It costs less. Choose based on your machine’s needs and budget.

Why is the mirror polish important?

A super smooth surface is crucial. It minimizes friction against delicate threads. Friction damages yarns. Friction creates static and lint. The mirror finish prevents this. It ensures smooth operation. Threads slide easily without snagging.

How long do these ceramic guides last?

They last much longer than metal guides. Alumina ceramic resists wear extremely well. It doesn’t rust or corrode. It handles chemicals used in processing. You replace them less often. This saves money over time. Downtime decreases.

Can I get custom sizes and shapes?

Yes. Manufacturers supply many standard sizes. They also make custom guides. You need guides that fit your specific machine. They offer precise dimensions. They offer special hole patterns. They offer unique mounting options. Provide your machine’s details for a perfect fit.

REQUEST A QUOTE

RELATED PRODUCTS

99 99.5 Alsint Alumina Ceramic Grinding Drilling Long Bar Alumina Ceramic Stick

Factory Direct Aluminum Alloy Bar Rod 2024 5083 6061 6063 6082 7075 Hot Extruded Sample Freely&Fast Delivery

Alumina 95 Ceramic Solid Bar Sharpener 3.2 x 19.2 Grindstone Support for Customization and Ceramic Parts Plates

Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod

Customized ZTA Al2O3 Alumina ZrO2 Zirconia Ceramic square Rod bar