Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

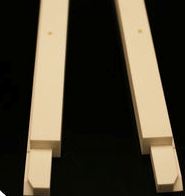

Description

Overview of New Products Bar Specification Customize Hight Purity Vacuum Bag Packing Indium Rod

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of New Products Bar Specification Customize Hight Purity Vacuum Bag Packing Indium Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of New Products Bar Specification Customize Hight Purity Vacuum Bag Packing Indium Rod

This indium rod item supplies customized specifications. We make these poles to your precise requirements. You select the diameter and length. We generate indium poles in numerous sizes. Common diameters range from regarding 5mm to 50mm. Sizes generally rise to 500mm. Various other measurements are feasible. Tell us your requirements.

High purity is essential. Our indium poles begin at 99.99% pure. Greater purity qualities like 99.995% and 99.999% are available. We assure stringent quality control. This ensures marginal contaminations. Your delicate applications require tidy product. We provide that consistency.

Each rod obtains special product packaging. We secure poles independently. They go into strong vacuum cleaner bags. This vacuum packing protects the indium. It protects against oxidation completely. Oxidation damages surface top quality. Vacuum bags keep the metal pristine. The bags are difficult. They withstand punctures throughout delivery. They also block wetness efficiently.

This packaging offers clear benefits. Your rods show up ready for use. The vacuum seal means no surface cleaning is needed. You conserve effort and time. The indium surface area remains bright and tidy. This is important for procedures like soldering or covering. Contamination risks are eliminated.

Our indium rods match requiring industries. Semiconductor manufacturing uses them. Thin film deposition processes need pure indium. Vacuum finishing applications rely on clean resources. Research study labs call for dependable products. These rods satisfy those high criteria.

Product traceability is very important. We give full documents. Certificates of Evaluation validate the pureness. Whole lot numbers track each set. You obtain total material background. This sustains your top quality systems.

Ordering is simple. Define your wanted pureness degree. Inform us the rod size and size. State the quantity you require. We take care of the rest. Manufacturing times are sensible. We ship around the world utilizing reliable carriers.

Applications of New Products Bar Specification Customize Hight Purity Vacuum Bag Packing Indium Rod

These custom indium rods come crammed in high-purity vacuum bags. This matters a lot. Oxygen direct exposure ruins ultra-pure steels. Vacuum securing maintains the indium tidy. This pureness is crucial for demanding uses.

Semiconductor producing needs this purity. Indium makes solder bumps and bonds. It layers surfaces. Also little pollutants create flaws. Our poles make sure trustworthy links on chips. Tidy indium means far better tool performance.

Photovoltaic panel production likewise uses pure indium. It forms electrical calls on solar batteries. Good get in touches with make best use of power capture. Contaminated indium reduces performance. Our vacuum-packed rods supply regular outcomes.

Accuracy electronic devices setting up depends on pure materials. Indium solders connect delicate parts. It bonds dissimilar materials. Impurities compromise joints. Failings happen. Our poles prevent this. They develop solid, trustworthy bonds.

Study labs call for high-purity materials. Researchers explore novel products. They establish brand-new digital gadgets. Trace elements alter results. Our vacuum-packed indium supplies a recognized, tidy base product. Experiments remain exact.

Bench spec permits modification. You get the specific size and shape required. This decreases waste. It saves machining time. Ready-to-use poles improve manufacturing.

Vacuum bag packaging safeguards the indium. It remains pure from manufacturing facility to your assembly line. You avoid contamination dangers. Quality stays constant. This streamlines your process. You concentrate on making your product.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of New Products Bar Specification Customize Hight Purity Vacuum Bag Packing Indium Rod

Here are five common questions about our new custom high purity vacuum packed indium rods:

What exactly is this product? This is indium metal formed into solid bars. We pack each bar individually inside a special vacuum bag. This keeps the indium pure and ready for your use.

Why is high purity important? Our indium rods are 99.99% pure. This level is critical for many advanced uses. Electronics and specialized manufacturing need this purity for reliable results. Lower purity indium can cause problems in sensitive processes.

What does the vacuum bag do? The vacuum bag removes all air around the indium rod. Air exposure causes indium to oxidize. Oxidation creates a surface film. This film can interfere with melting or bonding the indium later. The vacuum stops oxidation completely.

Can I get bars made to my specifications? Yes. We offer custom bar sizes. Tell us the length and diameter you require. We cut the indium rods to your exact sizes. You get the precise dimensions needed for your application.

How are the bars shipped? Each vacuum-sealed indium rod is packed securely. We use strong boxes with protective padding. This prevents damage during transit. Your order arrives safely and ready for immediate use.

REQUEST A QUOTE

RELATED PRODUCTS

KERUI 60 70 % High Alumina Hexagonal Brick Biporous or Porous Bar Hole Brick for Roller Kiln

End Cut High Wear Resistance High Polished 99% Alumina Bar

Industrial Aluminum Rod 1050 2024 T4 7075 T6 110mm 120mm 130mm Round Bar 1070 6061 2024 Alloy Material Cutting Service Available

82 the All-rounder AndPressure Transmitter with Ceramic Measuring Cell Radar Level Sensor

High Precision Customized ZTA Al2O3 Alumina ZrO2 Zirconia Ceramic Rod bar Ceramic Plunger