Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

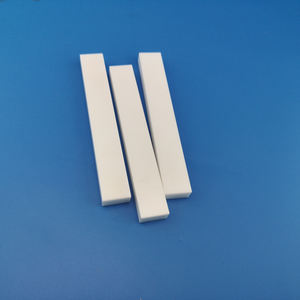

Overview of Polished Yttria-stabilized Zirconia Block Ceramic bar for Industry

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Polished Yttria-stabilized Zirconia Block Ceramic bar for Industry

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Polished Yttria-stabilized Zirconia Block Ceramic bar for Industry

This refined yttria-stabilized zirconia ceramic bar solves challenging commercial problems. It supplies severe hardness. This hardness battles put on exceptionally well. Components last longer in abrasive setups. The material endures really heats. Thermal shock resistance is solid. Abrupt temperature level changes create less breaking. This stability is vital for requiring processes.

YSZ ceramic maintains specific measurements. It stays the very same dimension dependably. This dimensional security is crucial for precise components. The fine polish produces an ultra-smooth surface area. This smoothness decreases rubbing. Relocating components operate much more efficiently. Contaminants struggle to adhere to the polished finish. Keeping points tidy is easier. This is important in sensitive environments like clinical tools or semiconductor production.

The zirconia base gives exceptional chemical resistance. It neglects most acids and antacids. Rust damage is considerably minimized. This ceramic does not carry out power. It functions as a reliable electric insulator. High mechanical toughness permits it to handle hefty lots. It stands up to breaking under pressure. These mixed residential or commercial properties make it optimal for precision tools, use components, pump seals, and high-temperature components.

Regular sizes are readily offered. Diameters vary from 5mm approximately 50mm. Sizes reach 300mm. Tighter resistances are achievable for critical uses. Surface area roughness can get to Ra 0.05 microns or better after professional polishing. This degree of level of smoothness fulfills the highest possible market criteria. The white color is typical. Customized formulas are feasible for specific requirements. This ceramic bar delivers constant efficiency. It manages rough problems where metals or plastics commonly stop working.

Applications of Polished Yttria-stabilized Zirconia Block Ceramic bar for Industry

Refined yttria-stabilized zirconia ceramic bars resolve challenging troubles in demanding sectors. These bars are unbelievably tough. They stand up to use remarkably well. This firmness indicates they last much longer than steel or other metals. Components made from them require replacing less usually.

Their surface area coating is extremely smooth. This smoothness reduces rubbing significantly. Devices run smoother. Less energy gets thrown away fighting rubbing. Warm build-up reduces too. This is crucial for accuracy tools and relocating components.

These ceramic bars handle severe heat well. They will not warp or crack under high temperatures. This makes them perfect for furnace parts. They work well in kilns and various other warm procedures. Steel parts would stop working promptly there.

Chemical resistance is one more key benefit. Acids and antacids don’t damage this zirconia. Extreme chemicals splash onto them without result. This is essential in chemical processing plants. Tools revealed to destructive liquids stays intact longer.

Industries use these refined bars for details tasks. They make exceptional overviews and fixtures for grinding makers. The smooth surface area secures delicate work surfaces. They operate reliably as extrusion craves hot steels or plastics. Furnace rollers made from this ceramic action products efficiently inside ovens. They work as robust wear plates in pumps managing unpleasant slurries. Precision seals and bearings made from this product last much longer under stress. Semiconductor manufacturing relies upon them for secure, non-contaminating elements.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Polished Yttria-stabilized Zirconia Block Ceramic bar for Industry

Polished Yttria-Stabilized Zirconia Block Ceramic Bar: Key Questions

What is this YSZ block ceramic bar?

This is a solid ceramic piece made from zirconium dioxide stabilized with yttria. We machine it to precise dimensions. It has a very smooth, polished surface finish. This material offers great strength and toughness.

Why use polished YSZ blocks?

These blocks resist extreme heat very well. They handle high temperatures without breaking down. They are also very hard and resist wear. This makes them last longer in tough conditions. They are chemically stable too. Harsh chemicals won’t damage them easily. The smooth surface reduces friction.

Where are these blocks typically used?

Factories use them in places needing durable, heat-resistant parts. Common uses include furnace linings and kiln furniture. They work well as thermal barriers. Precision machine shops use them for wear plates and guides. Labs use them for crucibles and sample holders.

What sizes and shapes are available?

We offer standard sizes like rectangular bars and cylindrical rods. Common dimensions range from small squares (10mm x 10mm) to larger bars (100mm x 100mm). Lengths vary too. We can make custom sizes. Tell us what you need.

Can I machine this material further?

Yes, you can machine it, but it’s difficult. YSZ is extremely hard. Standard tools wear out fast. You need special diamond tools. You need experience working with advanced ceramics. Tell us your final part specs. We might machine it for you before delivery. This saves you time and effort.

How does YSZ compare to alumina ceramic?

YSZ is generally tougher than alumina. It resists cracks better under stress. YSZ also handles thermal shock better. Sudden temperature changes are less likely to break it. Both are hard and heat resistant. YSZ often performs better in the most demanding jobs.

REQUEST A QUOTE

RELATED PRODUCTS

Industry Insulator Dry Pressing 1- 8 Holes Ceramic Bar for Heating Circle

Industrial Aluminum Rod 1050 2024 T4 7075 T6 110mm 120mm 130mm Round Bar 1070 6061 2024 Alloy Material Cutting Service Available

Lsostatic Pressured Yttria ZrO2 Ceramic Bar Zirconia Ceramic Plunger Rod With Metal Assemblies

High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

Zirconia Ceramic Cylindrical Bar Industrial Ceramic Plunger Zirconium Oxide Piston Ceramic Rod