Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

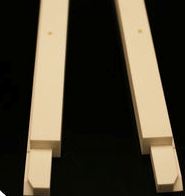

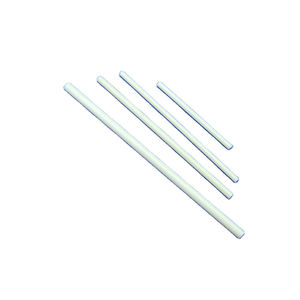

Overview of Professional Manufacture 99%Alumina Ceramic bar Ceramic Piston Rod

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Professional Manufacture 99%Alumina Ceramic bar Ceramic Piston Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Professional Manufacture 99%Alumina Ceramic bar Ceramic Piston Rod

Our Expert Manufacture 99% Alumina Ceramic bar works as a high-performance Ceramic Piston Rod. It contains 99% alumina for outstanding purity. This ensures impressive hardness and toughness. The product withstands severe wear efficiently. It exceeds metal parts in abrasive settings. The ceramic rod handles high temperatures up to 1000 ° C accurately. It maintains structural honesty under thermal stress and anxiety.

Chemical resistance is one more vital advantage. The rod stands up to acids and alkalis without degradation. It suits harsh commercial environments. Its non-reactive nature protects against contamination. This makes it secure for food and pharmaceutical usages. The surface finish is incredibly smooth. This lessens friction throughout procedure. It enhances mechanical performance and decreases energy consumption.

Electric insulation properties are excellent. The pole obstructs high-voltage currents safely. It prevents short circuits in sensitive tools. Dimensional stability is consistent across temperature adjustments. This ensures exact motion in equipment. We produce typical diameters from 3mm to 50mm. Lengths encompass 500mm. Customized dimensions are available. We device rods to exact specifications for your application.

Normal usages include hydraulic pumps and precision valves. It operates in mechanical seals and semiconductor tools. Clinical devices additionally utilize this part. The ceramic piston pole extends tools lifespan considerably. It decreases maintenance frequency and substitute expenses. We use sophisticated production methods. This supplies uniform high quality throughout all products.

Applications of Professional Manufacture 99%Alumina Ceramic bar Ceramic Piston Rod

Professional manufacture 99% alumina ceramic bar develops superb ceramic piston poles. These rods are essential parts popular work. Average steel poles wear quickly or rust. Alumina ceramic poles solve these troubles.

The material is incredibly hard. This firmness indicates the pole surface stays smooth much longer. Friction uses it down extremely gradually. Less friction additionally merciless run smoother. Devices need less power. This conserves power in time.

Alumina ceramic withstands deterioration completely. Extreme chemicals or seawater will not harm it. This makes it suitable for chemical processing pumps or marine devices. Steel rods fail promptly right here. Our ceramic poles last.

These rods handle extreme warmth easily. They don’t change dimension much when warm. This thermal stability is critical. Semiconductor manufacturing devices use them. Furnace components require this dependability. Steel rods warp or damage under heat.

The product is also an electric insulator. This stops undesirable electric currents. Applications in electronic devices or high-voltage devices advantage. Safety boosts. Signal interference reduces.

Clinical devices use these rods also. They are biocompatible and chemically inert. They will not respond with body fluids or cleaning up representatives. Accuracy liquid control systems depend on them. They supply tidy, trusted procedure.

Industrial automation uses ceramic piston poles heavily. High-speed machines need their reduced wear and tightness. Assembly line remain running much longer. Downtime decreases. Upkeep expenses drop substantially.

Food and beverage equipment gains advantages. The smooth surface stops microorganisms accumulation. Cleaning up is easy. The product will not infect items. Health requirements are simpler to fulfill.

Our ceramic piston poles surpass metal continually. They provide longer life. They reduce operating costs. They enhance maker reliability. They deal with difficult settings metal can not.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Professional Manufacture 99%Alumina Ceramic bar Ceramic Piston Rod

Professional Manufacture 99% Alumina Ceramic Bar Ceramic Piston Rod FAQs

What’s the main benefit of 99% alumina ceramic for piston rods?

Alumina ceramic is extremely hard. It resists wear far better than metal. This means piston rods last much longer. Alumina ceramic also handles very high temperatures. It won’t deform under heat like some metals. It resists chemicals too. Acids and bases won’t corrode it. This makes it reliable in tough conditions.

How smooth can you make the rod’s surface?

We achieve extremely smooth surfaces. Our grinding and polishing are precise. Surface roughness (Ra) can be below 0.2 micrometers. This smoothness reduces friction significantly. Less friction means less energy loss. Less friction also means less wear on seals. Smooth operation is guaranteed.

Is this ceramic strong enough for heavy use?

Yes. 99% alumina ceramic is very strong. It has high compressive strength. It handles heavy loads without cracking. It’s also very stiff. The rod won’t bend or flex much under pressure. This ensures precise movement and positioning. It’s built tough for industrial applications.

Can you make custom sizes and shapes?

Yes. We specialize in custom manufacturing. Tell us the exact diameter and length you need. We can make various cross-sections too. Special end shapes or features are possible. We work to your specific drawings. We meet precise dimensional tolerances.

How do I handle and install these rods safely?

Handle alumina ceramic rods carefully. Avoid dropping them or hitting them hard. Ceramic is brittle under impact. Use proper support during installation. Don’t apply uneven force. Make sure mating parts fit correctly without forcing. Protect the rod surface from scratches. Proper handling prevents damage before use.

REQUEST A QUOTE

RELATED PRODUCTS

High Fine Quality AIN Ceramics Aluminium Nitride Ceramic Tube / Rod / Bar

Cheaper Low Black and White and Customized Aluminium Spacer Bar for Insulating Glass

Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar

Custom alumina high temperature ceramic bar/strips/blocks

Custom Wear Resistant Alumina Oxide Al2o3 Ceramic Rod Wear Resistant Aluminum Oxide Insulation bar