Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

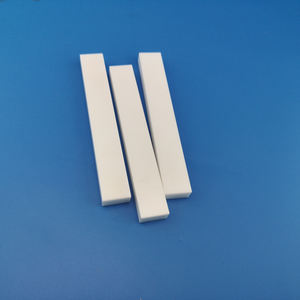

Overview of SHENGYIDAcustom Alumina Rod Al2o3 Seramik Stopper Shaft bar Ceramic Roller s

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of SHENGYIDAcustom Alumina Rod Al2o3 Seramik Stopper Shaft bar Ceramic Roller s

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of SHENGYIDAcustom Alumina Rod Al2o3 Seramik Stopper Shaft bar Ceramic Roller s

SHENGYIDA makes custom alumina rods. These rods are Al2O3 ceramic. They serve many tough jobs. Alumina ceramic is very hard. It resists wear extremely well. These rods won’t scratch easily. They last much longer than metal parts. This saves money over time.

These ceramic rods handle extreme heat. They work fine in high-temperature settings. They won’t melt or weaken. Sudden temperature changes are okay. The rods won’t crack from thermal shock. This makes them reliable for furnaces or kilns.

Chemical resistance is another big plus. Acids and alkalis don’t damage alumina. Harsh chemicals are no problem. The rods stay strong in corrosive places. This is vital for chemical plants or labs.

Electrical insulation is important. Alumina rods don’t conduct electricity. They are perfect insulators. You can use them safely around electrical parts. They prevent short circuits effectively.

We offer precise custom sizes. Tell us the diameter you need. Tell us the exact length. We make rods to your measurements. Tight tolerances are standard. The rods fit your equipment perfectly every time.

Surface finish matters. Our rods have a smooth, consistent surface. This minimizes friction. It helps things slide or roll easily. We control the quality carefully.

These rods are incredibly strong. They resist bending forces well. High mechanical strength is guaranteed. They support heavy loads without breaking. Impact resistance is also good.

Custom shapes are possible. Round rods are common. We make other shapes too. Just ask about your specific design. Our alumina rods work as shafts, rollers, or stoppers. They are ideal for guiding, moving, or positioning materials.

The material is alumina oxide ceramic. Purity levels are high. This ensures top performance. We use grades like 95% or 99% Al2O3. Each grade offers specific benefits. Tell us your application needs. We help pick the best material.

Applications of SHENGYIDAcustom Alumina Rod Al2o3 Seramik Stopper Shaft bar Ceramic Roller s

SHENGYIDA custom alumina rods solve tough problems in many industries. Alumina ceramic is Al2O3. This material offers special properties regular metals or plastics lack. It handles extreme heat very well. Furnaces and kilns get extremely hot inside. These rods work reliably there. They won’t melt or warp under high temperatures. Chemical resistance is another major benefit. Harsh acids and bases damage many materials. Alumina ceramic stands up to these corrosive chemicals. This makes it perfect for chemical processing equipment and lab tools.

Wear resistance is outstanding. Moving parts often rub together causing friction and damage. Alumina rods last much longer than steel or other ceramics in abrasive conditions. Electrical insulation is crucial in many applications. Alumina ceramic does not conduct electricity. This property is vital in electronics and high-voltage settings. Semiconductor manufacturing uses these rods as precision parts. They hold silicon wafers securely without contamination. The ceramic stays stable and clean.

Thermal management systems need materials that move heat efficiently. Alumina rods transfer heat effectively. They are used in heat sinks and other thermal control devices. Textile machinery faces constant friction. Ceramic rollers made from alumina guide thread smoothly. They reduce wear and keep machines running longer. Food processing demands hygiene and durability. Alumina parts meet strict standards. They resist corrosion from cleaning agents and food acids. Measurement instruments require precision. Alumina rods provide dimensional stability. They don’t expand or contract much with temperature changes. This ensures accurate readings. Laser technology uses these rods too. They guide laser beams precisely. High-power lasers generate intense heat. Alumina handles this heat reliably. Furnace construction relies on strong, heat-proof parts. Custom alumina rods serve as structural supports or thermocouple protection tubes. They endure the furnace environment for years. Medical devices sometimes use biocompatible alumina. Its hardness and smoothness are useful for specific tools.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of SHENGYIDAcustom Alumina Rod Al2o3 Seramik Stopper Shaft bar Ceramic Roller s

What is the Alumina Rod used for? Alumina Rods serve in high heat environments. They work as rollers in kilns. They act as shafts in pumps. They function in semiconductor tools. They handle electrical insulation. They operate inside furnaces. They are found in medical devices. What are the key properties of the Alumina Rod? Alumina Rods resist extreme heat. They withstand temperatures to 1800°C. They are very hard. They fight wear well. They insulate electricity perfectly. They stay stable chemically. They ignore acids and alkalis. They bear heavy loads. They keep their shape. How is the Alumina Rod made? We start with pure alumina powder. The powder gets pressed into forms. Next it gets sintered at high heat. This creates a dense strong rod. We machine rods for exact sizes. We control every step. We ensure quality consistency. Why choose SHENGYIDA for Alumina Rods? SHENGYIDA has long experience. We produce custom ceramic parts. We use top-grade materials. Our manufacturing is precise. We test all batches. Our prices are competitive. We deliver promptly. We support customers well. We serve clients worldwide. What sizes and shapes are available? We offer rods in many sizes. Diameters go from 1mm to 100mm. Lengths reach up to 1000mm. We make round rods. We make square rods. We make special shapes. We follow your drawings exactly. We add holes or threads if needed.

REQUEST A QUOTE

RELATED PRODUCTS

Electrical Insulation Machined Alumina Ceramic bar Strip

7068 T6 6061 6511 7005 Series Alloy Round 1350 10mm Aluminum Metal Bars

New Design Whole Alumina Ceramic Eyelets Yarn Guide Parts Ceramic Bar for Textile Machinery

Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

Factory s 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod