Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

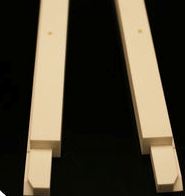

Overview of Silicon Carbide Alumina Zirconia Aluminum Nitride Silicon Nitride Boron Nitride Ceramic Solid Round Ceramic Bar Ceramic Rod

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Silicon Carbide Alumina Zirconia Aluminum Nitride Silicon Nitride Boron Nitride Ceramic Solid Round Ceramic Bar Ceramic Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Silicon Carbide Alumina Zirconia Aluminum Nitride Silicon Nitride Boron Nitride Ceramic Solid Round Ceramic Bar Ceramic Rod

Our ceramic rods are strong round bars crafted from high-grade materials. You get Silicon Carbide, Alumina, Zirconia, Aluminum Nitride, Silicon Nitride, or Boron Nitride alternatives. Each material brings distinct strengths. These poles are extremely hard. They resist use incredibly well. They handle high temperatures without breaking down. Some stand up to over 2000 ° C quickly. They additionally reject chemical rust. Acids and antacids do not damage them. Electrical insulation is one more essential feature. Boron Nitride poles succeed below. Thermal conductivity varies. Light weight aluminum Nitride transfers warmth efficiently. Silicon Carbide does as well. Silicon Nitride manages thermal shock superbly. Zirconia provides superior strength. It prevents splits under tension.

Accuracy issues for these poles. They can be found in precise sizes and sizes. Uniformity is guaranteed batch after batch. Surface area surfaces are smooth. Tolerances stay tight. These residential or commercial properties match demanding markets. Semiconductor producing uses them for wafer handling. Aerospace applications require their heat resistance. Clinical tools take advantage of biocompatibility. Industrial machinery relies upon their resilience. Furnace elements utilize them for temperature level stability. Automotive sensing units incorporate them for precision.

Product choice relies on your demands. Silicon Carbide helps rough environments. Alumina offers cost-effective firmness. Zirconia is perfect for effect resistance. Aluminum Nitride fits high-power electronic devices. Silicon Nitride deals with fast temperature level modifications. Boron Nitride offers electric insulation requirements. Customized sizes are readily available. Special sizes or lengths are no worry. Quality checks ensure dependability. Every pole meets rigorous requirements. Issues are removed with rigorous screening. Performance is predictable in extreme conditions. Metal parts frequently fall short where these ceramics succeed. Longer life span minimizes downtime. Upkeep costs go down significantly.

Applications of Silicon Carbide Alumina Zirconia Aluminum Nitride Silicon Nitride Boron Nitride Ceramic Solid Round Ceramic Bar Ceramic Rod

These ceramic poles serve tough jobs. They come from special products. Silicon carbide rods take care of severe wear. They function well in rough circumstances. Heater components use them usually. Alumina poles withstand high warmth. They protect electric parts dependably. Chemical plants pick alumina for rust resistance. Zirconia rods are unbelievably strong. They use excellent crack durability. Reducing tools and bearings use zirconia rods. Medical implants often pick zirconia for biocompatibility.

Light weight aluminum nitride poles handle warmth fantastically. They move heat away fast. Electronic devices needing cooling rely upon aluminum nitride rods. Semiconductor tools utilizes them frequently. Silicon nitride poles stand up to high temperatures and stress. They withstand thermal shock properly. Engine elements and wind turbine parts use silicon nitride poles. Boron nitride rods supply superb electric insulation. They lube smoothly at heats. Crucibles and high-temperature fixtures need boron nitride rods.

These poles last much longer than metal in extreme conditions. They keep their shape under anxiety. Factories use them where metals fall short. They cut down on maintenance costs. Engineers select the product matching the task’s needs. Warm, wear, chemicals, or electrical power lead the option. Each ceramic pole type provides distinct benefits. Efficiency depends upon the details ceramic residential properties.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Silicon Carbide Alumina Zirconia Aluminum Nitride Silicon Nitride Boron Nitride Ceramic Solid Round Ceramic Bar Ceramic Rod

Here are common questions about our ceramic rods made from silicon carbide, alumina, zirconia, aluminum nitride, silicon nitride, and boron nitride:

What are these ceramic rods made of? We use several advanced technical ceramics. These include silicon carbide (SiC), alumina (Al2O3), zirconia (ZrO2), aluminum nitride (AlN), silicon nitride (Si3N4), and boron nitride (BN). Each material offers unique properties.

Why choose ceramic rods over metal rods? Ceramic rods outperform metals in extreme conditions. They handle much higher temperatures. They resist wear much better. They are also very hard. Ceramics often resist chemical attack better than metals. They are lighter than most metals too.

What are the main uses for these rods? Their uses are wide. They work in high-temperature furnace parts. They serve as strong insulators in electronics. They act as durable guides and rollers. They are used in demanding wear parts. They function in harsh chemical environments. They are essential in semiconductor processing equipment.

How do I pick the right ceramic material? The best material depends on your specific needs. Silicon carbide is excellent for extreme wear and heat. Alumina offers good overall performance and value. Zirconia provides high strength and toughness. Aluminum nitride conducts heat well and insulates electrically. Silicon nitride is great for thermal shock resistance. Boron nitride is easily machined and lubricates itself.

Can I get custom sizes and shapes? Yes, absolutely. We offer extensive customization. We make rods to your exact diameter and length requirements. We provide precision grinding for tight tolerances. We can supply rods in various surface finishes. We can also machine more complex shapes upon request.

REQUEST A QUOTE

RELATED PRODUCTS

Wear Resistance Zirconia Ceramic Stick Zro2 Ceramic Bar Zirconia Ceramic Rod

Magnesium Alloy bar AZ31B AZ91D AZ80 ZK60A WE43 Mg Rod/bar Magnesium Round bar

High Hardness Ultrafine Precision Modern Al2O3 Alumina Ceramic Strip Stick Bar

Quality Aluminium Spacer bar for Aluminum Frame Window

Aluminum Flat Bar High Quality Rectangle 6061 T6 Aluminium Flat Bar / Square Bar Per Kg