Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

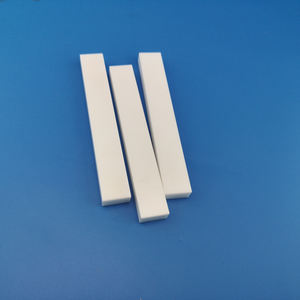

Overview of Zirconia Ceramic Cylindrical Bar Industrial Ceramic Plunger Zirconium Oxide Piston Ceramic Rod

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Zirconia Ceramic Cylindrical Bar Industrial Ceramic Plunger Zirconium Oxide Piston Ceramic Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Zirconia Ceramic Cylindrical Bar Industrial Ceramic Plunger Zirconium Oxide Piston Ceramic Rod

This zirconia ceramic round bar serves as a commercial ceramic plunger, piston, or pole. It’s made from zirconium oxide ceramic. This material is unbelievably tough. It places near the top of the hardness scale. This hardness gives it superb wear resistance. It outlives numerous metals significantly. Parts last a lot longer prior to requiring substitute. This saves money over time.

Zirconia ceramic offers low rubbing. Surfaces move smoothly against it. This lowers power loss in equipments. Makers run more efficiently. It also minimizes warmth buildup. Warm can damage elements. This ceramic handles high temperatures well. It works reliably in warm atmospheres. Steel parts might warp or weaken there.

Chemical resistance is another major benefit. Zirconia withstands attack from several acids and antacids. It won’t rust like metal. This makes it perfect for severe chemical handling. It carries out consistently in hostile liquids. You prevent contamination concerns. Product purity stays high.

The product is electrically shielding. It doesn’t perform electrical power. This is crucial in many electrical applications. It avoids brief circuits. It provides safe seclusion. Its non-magnetic nature is also useful. It works where magnetic fields cause problems. Interference is eliminated.

Accuracy machining is possible. We make these ceramic plungers, pistons, and rods to precise measurements. Tolerances are limited. This ensures ideal fit and feature. They function reliably sought after machinery. Applications include pumps, shutoffs, and precision tools. They are found in the vehicle, aerospace, and medical markets. They supply regular efficiency under stress.

Applications of Zirconia Ceramic Cylindrical Bar Industrial Ceramic Plunger Zirconium Oxide Piston Ceramic Rod

Zirconia ceramic round bars, plungers, pistons, and poles fix hard troubles in many markets. These components are unbelievably difficult. They stand up to wear incredibly well. This suggests they last a lot longer than metal parts in unpleasant problems. They manage warmth well also. This stability is crucial for high-temperature procedures.

Manufacturing facilities and automation utilize these ceramic components extensively. They act as specific bettors in pumps and valves. They relocate liquids accurately without putting on down. Their smooth surface area reduces friction. This keeps machinery running successfully. They are key components in high-precision measuring devices. They provide steady, wear-free motion.

The automobile sector relies upon them. They serve as long lasting pistons in fuel injection systems. They endure constant pressure and chemical exposure. Their reduced thermal growth keeps tolerances tight. This ensures regular engine performance. They are additionally found in sensing unit elements. They provide exact readings under extreme problems.

Medical and oral areas profit greatly. Zirconia is biocompatible. It is risk-free for use inside the human body. These ceramic rods form parts of surgical instruments. They offer strength and deterioration resistance. They are important in dental milling makers. They develop accurate crowns and bridges. Their solidity guarantees sharp reducing edges.

Electronics manufacturing requirements their homes. They are outstanding electrical insulators. They perform dependably in high-voltage applications. They are utilized as shielding shafts and spindles. They isolate sensitive components. Their dimensional stability is critical. It keeps placement in delicate assembly procedures.

These zirconia parts are chosen for requiring work. They offer premium efficiency where metals stop working. They give integrity, precision, and longevity. Their distinct properties make them essential throughout industries.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Zirconia Ceramic Cylindrical Bar Industrial Ceramic Plunger Zirconium Oxide Piston Ceramic Rod

What is zirconia ceramic?

Zirconia ceramic comes from zirconium oxide. It is a tough material. It handles high stress well. It resists wear and corrosion. It is very hard. It works in harsh conditions.

Why choose zirconia ceramic plungers?

Zirconia plungers last longer than metal ones. They resist chemical damage. They handle high pressure smoothly. They reduce friction. They need less maintenance. They save costs over time.

Where are these ceramic rods used?

These rods fit many industries. Automotive systems use them. Medical devices use them. Pump and valve manufacturers use them. Textile machinery uses them. They work in high-wear spots.

How does zirconia compare to alumina ceramic?

Zirconia is stronger than alumina. It resists cracks better. It handles impacts better. Alumina is cheaper. Alumina is harder but more brittle. Zirconia suits tougher jobs.

Can zirconia handle heat and pressure?

Yes. It works at very high temperatures. It handles up to 1000°C. It survives high pressure. It does not break easily. It keeps its shape under stress.

REQUEST A QUOTE

RELATED PRODUCTS

1060 2014 5052 Aluminum Alloy Round Square Bar Ingot 1100 Grade 10mm 20mm 50mm Diameter 6061 T6 7075 5A06 Aluminum Bar Rod

99%/95%Al2o3 Alumina ceramic stick refractory material ceramic bar

Wear Resistance Zirconia Ceramic Stick Zro2 Ceramic Bar Zirconia Ceramic Rod

Industrial heating alumina ceramic rods/Al2O3 bar

Factory Whole 1060 1070 PURE Aluminum Rectangular Flat Bar 10mm 8mm 6mm Aluminum Busbar