Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

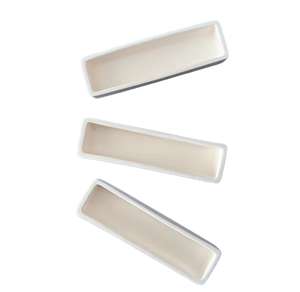

Overview of 1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat

1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of 1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat)

Specifications of 1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat

This alumina ceramic vaporizing watercraft manages severe warm. It works dependably at temperature levels getting to 1600 degrees Celsius. The watercraft is made from high pureness alumina ceramic. This material uses outstanding thermal security. It resists thermal shock effectively. This implies it won’t split easily during quick home heating or cooling down cycles. The watercraft has a typical 5ml capacity. This dimension prevails for numerous lab and commercial evaporation jobs. Its measurements are practical for fitting into numerous heater setups. The ceramic building gives solid chemical resistance. It withstands assault from several liquified steels and salts. This makes it appropriate for demanding procedures like vacuum metallization. The watercraft preserves its form and integrity under long term high warm. This ensures constant performance over lots of usages. Its smooth surface area enables tidy dissipation of products. Residue build-up is reduced. This streamlines cleansing between runs. The high thickness alumina stops contamination of your source products. Pureness is crucial for thin film deposition. These boats are durable and lasting. They use great value compared to much less durable options. They are vital tools for applications requiring precise, heat evaporation. Regular usages consist of producing thin films in optics, electronics, and semiconductors. The watercraft is created for straight insertion right into high temperature zones. It performs reliably in vacuum cleaner or inert gas environments.

(1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat)

Applications of 1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat

These sturdy 5ml alumina ceramic vaporizing watercrafts deal with severe heat. They take care of temperatures getting to 1600 degrees Celsius. This makes them essential devices in demanding commercial procedures. Numerous markets depend on their special properties.

These watercrafts excel in slim movie deposition. This process coats materials onto surfaces. Vacuum dissipation often utilizes these boats. The boat holds the material you want to evaporate. Intense warmth then evaporates that product. The vapor deposits as a thin layer. Alumina ceramic withstands this ruthless atmosphere. Other materials could thaw or infect the vapor. These watercrafts resist chemical assault. They won’t weaken when holding metals. They work well with light weight aluminum. They work well with chromium. They function well with numerous various other steels. They also manage particular oxides. This chemical security is important. It ensures pure vapor deposition. It prevents unwanted contaminations in the final coating.

The 1600-degree ability is crucial. Many high-melting-point metals need this warm. The watercrafts keep structural stability. They do not warp or fracture under thermal anxiety. This reliability is essential for regular outcomes. It prevents costly downtime. It prevents process failures. These boats are actual workhorses.

You discover them in semiconductor manufacturing. They deposit specific steel layers onto silicon wafers. The electronics industry utilizes them thoroughly. They produce conductive paths. They create protective finishes. Optical coating manufacturing counts on them. They aid make lenses. They assist make mirrors with certain reflective residential or commercial properties. Aerospace applications demand their performance. They coat wind turbine blades. They coat other high-stress parts. Study laboratories value their precision. They allow controlled experiments in materials scientific research.

The 5ml dimension matches smaller-scale work. It permits efficient use costly materials. It provides outstanding control over deposition prices. These watercrafts stand up to repeated thermal biking. They warm up quickly. They cool down quickly. This speeds up manufacturing cycles. Their longevity saves money gradually. They exceed less costly choices considerably. They deliver constant, high-grade thin films.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat

FAQs: 1600°C High Temperature Resistant 5ml Alumina Ceramic Evaporating Boats

What temperature can this boat handle?

This alumina ceramic evaporating boat withstands temperatures up to 1600 degrees Celsius. It stays stable under intense heat. This makes it perfect for demanding high-temperature tasks.

Why is alumina ceramic used?

Alumina ceramic offers exceptional heat resistance. It resists thermal shock well. Alumina ceramic also provides excellent chemical inertness. This means it won’t easily react with most materials evaporated inside it. The high purity ensures clean results.

What applications suit this 5ml boat?

This 5ml size works best for lab-scale evaporation. Use it in thermal evaporation coating systems. It’s ideal for evaporating small amounts of metals like aluminum or gold. Thin film deposition processes often need this size. Research labs find it very useful.

How do I clean and maintain it?

Handle the boat carefully. Alumina ceramic is strong but brittle. Avoid impacts. Clean it after each use. Remove any leftover residue gently. A soft brush often works well. Ultrasonic cleaning with suitable solvents helps sometimes. Inspect it regularly for cracks. Replace damaged boats immediately.

Is this boat safe for high vacuum?

Yes, this alumina ceramic boat performs reliably in high vacuum environments. Its dense structure prevents outgassing. This maintains vacuum integrity. It ensures consistent evaporation rates. Always follow your specific equipment’s operating procedures.

(1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat)

REQUEST A QUOTE

RELATED PRODUCTS

LPCVD Cantilever Boat Ceramic Vacuum Chuck Alumina Ceramic Wafer Holder

95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

Refractory Laboratory Alumina Ceramic Boat

95% 99% Small Size Square Alumina Ceramic Sagger with Lid Alumina Ceramic Boat Uesd for Laboratory

95% 99% Alumina Ceramic Crucible High Temperature Resistant Ceramic Sagger Boat with Lid Product