Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

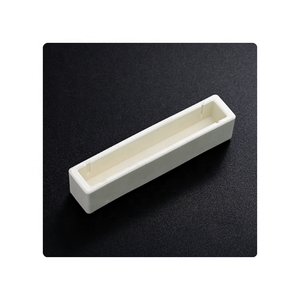

Overview of 95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat

95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of 95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat)

Specifications of 95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat

This alumina ceramic crucible supplies high performance. It’s made from 95% to 99% pure light weight aluminum oxide (Al2O3). This high purity offers superb residential or commercial properties. The crucible stands up to deterioration quite possibly. It takes care of solid acids and bases successfully. Numerous harsh chemicals won’t harm it. This makes it trustworthy for requiring chemical procedures. It withstands very high warm. You can utilize it securely up to 1750 ° C (3182 ° F). Its thermal shock resistance is great. Sudden temperature modifications cause much less fracturing. The material is very hard. It ratings high up on the Mohs range. This hardness implies it stands up to wear and abrasion. The crucible has a dense structure. Its reduced porosity stops material absorption. Contamination dangers are reduced. This thickness adds to its stamina. It handles mechanical stress much better. The ceramic boat form is common. It fits sample handling in tube heating systems. These crucibles work for melting steels. They are good for sintering powders. Warmth therapy procedures utilize them frequently. Analytical laboratories rely on them. The ceramic is electrically insulating. It performs well in high-temperature electric applications. These crucibles are dimensionally stable. Their shape holds under thermal biking. Constant results are simpler to accomplish. You obtain a resilient, high-temperature container.

(95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat)

Applications of 95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat

These alumina ceramic crucibles work well for laborious needing heat and chemical resistance. They include primarily light weight aluminum oxide. This product handles severe temperature levels easily. It remains solid also above 1500 ° C. Several furnaces get that warm. These crucibles don’t mind.

Rust is a big problem with cheaper materials. Acids and bases eat them away. Not these alumina crucibles. They stand up to most chemicals. This includes solid acids and liquified salts. Your products stay pure. Contamination damages experiments and manufacturing.

The form matters as well. These resemble little watercrafts. This ceramic watercraft style is clever. It holds powders or liquids securely. You can slide them in and out of warm areas efficiently. They will not tip conveniently. Dealing with examples is simpler.

People use them anywhere requiring integrity. Labs rely upon them for thawing metals. They work for sintering powders right into strong components. Firing ceramics requires steady containers. These supply. Semiconductor plants utilize them for processing silicon wafers. They keep sensitive procedures tidy.

Sturdiness conserves cash. These crucibles last longer than cheaper choices. They withstand thermal shock. Sudden temperature level adjustments break weak products. Alumina manages the stress and anxiety. You prevent constant substitutes. Downtime expenses money.

These crucibles fit exact job. Stability is vital for regular results. They offer that. You obtain foreseeable performance every single time. Heat spreads equally inside. Your materials process consistently. This reliability issues in research study and production. Performance remains high set after set.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat

Here are five common questions about our 95-99% alumina ceramic crucibles:

What temperature can these crucibles handle? They withstand very high heat. Standard crucibles manage 1600°C easily. Higher purity options handle up to 1800°C. Always check the exact grade’s rating first.

Will chemicals damage the crucible? Alumina ceramic resists most acids and alkalis well. It handles strong acids like sulfuric or nitric acid. It handles strong bases like sodium hydroxide too. Avoid hydrofluoric acid and strong phosphoric acid. They cause damage.

Can I heat the crucible up fast? Be careful. Alumina ceramic resists thermal shock better than many materials. Sudden temperature changes risk cracks. Heat it gradually. Cool it slowly too. This practice protects your crucible.

How do I clean it after use? Cleaning is simple. Use hot water and a brush first. Stubborn residue needs soaking in strong acid or alkali sometimes. Use the compatible chemicals mentioned earlier. Rinse thoroughly with water afterwards. Never use abrasive scouring pads.

What are these crucibles mainly used for? Their heat and chemical resistance make them versatile. They are ideal for melting metals. They are good for processing powders. They work for sintering materials. They handle calcination processes. Labs and industries use them widely.

(95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat)

REQUEST A QUOTE

RELATED PRODUCTS

99% Corundum Ceramic Crucible Evaporation Alumina Ceramic Boat for Laboratory

XTL Sintyron in Stock Thermal Analysis High Purity Al2o3 Alumina Ceramic Crucible Boat

99% High Alumina Ceramic Crucible Cylinder Al2O3 Alumina Combustion Boat With Lid , Rectangle Alumina Ceramic Boats Crucible

Customized Alumina Molten Metal Crucible Laboratory 95 Al2O3 Ceramic Boat

100mmX20mmX20mmHigh Temperature Trapezoidal Shape Ceramic Alumina Boat Crucible for Melting Furnace