Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

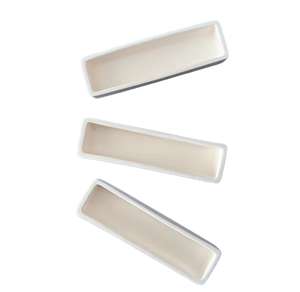

Overview of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts)

Specifications of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

This 99.5% Al2O3 alumina ceramic watercraft is a high-purity industrial element. It deals with severe warm remarkably well. Its optimum solution temperature level gets to 1800 ° C. This product offers exceptional thermal shock resistance. Sudden temperature level adjustments will not quickly split it. The alumina purity is really high. This decreases contamination risks. Sensitive products stay risk-free throughout processing.

The ceramic flaunts severe solidity. It ranks near the top on the Mohs range. This solidity provides excellent wear resistance. Parts last much longer under unpleasant problems. It stands up to scratches and dents efficiently. Chemical resistance is an additional major strength. The ceramic withstands strike from lots of acids and antacids. Rough chemical settings won’t weaken it quickly. It performs dependably in corrosive settings.

Electrical insulation residential or commercial properties are exceptional. This ceramic avoids existing circulation accurately. High voltage applications are secure. The product thickness is high. This offers it excellent structural strength. It preserves its form under heavy loads. Dimensional stability is accurate. Resistances stay limited even at heats. Parts fit accurately within equipment.

The surface coating is commonly extremely smooth. This minimizes fragment adhesion. Contamination control is less complicated. Cleaning in between uses is uncomplicated. These ceramic boats match requiring furnace applications flawlessly. Usual usages consist of semiconductor wafer handling. They work well in kilns and sintering heaters. Chemical vapor deposition (CVD) refines use them. Diffusion processes rely upon their stability. They act as crucial carriers and trays. Individuals benefit from consistent, dependable efficiency. Manufacturing uptime rises. Upkeep requires decline.

(99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts)

Applications of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

Our 99.5% Al2O3 alumina industrial ceramic watercrafts are high pureness ceramic components. These elements manage extreme conditions across lots of markets. They work well in semiconductor production. They bring silicon wafers through heat procedures. The product remains secure and doesn’t infect sensitive materials. Heating system applications utilize these ceramic boats too. They sustain items during firing or warmth therapy. Their high temperature resistance prevents bending or cracking. This guarantees constant outcomes every time.

LED manufacturing relies upon these ceramic components. They hold materials during crystal development stages. The high pureness stops undesirable responses. Solar cell production needs them also. They handle delicate photovoltaic or pv materials in rough settings. Chemical processing plants use alumina ceramic watercrafts. They resist acids and antacid successfully. This prolongs their service life and reduces replacement prices.

Laboratories benefit from these ceramic parts. They function as crucibles or example owners. Their thermal shock resistance handles fast temperature changes. Electronic devices making uses them for insulation. They supply reliable electrical isolation in important locations. Metallurgy operations rely on these boats for sintering steel powders. They preserve architectural stability under extreme warmth.

These ceramic components offer exceptional mechanical toughness. They endure physical anxiety without damages. Their hardness decreases wear with time. This conserves money on constant component adjustments. They run smoothly in vacuum or regulated environments. Their dimensional stability ensures specific placement. Industries pick them for trustworthy efficiency. They function longer than several choices. This decreases downtime and upkeep demands. They match computerized production lines completely. Their consistent quality supports high result requirements. Numerous fields trust fund these alumina ceramic options daily.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

What is this ceramic boat made of?

It uses 99.5% pure alumina (Al2O3). This high purity matters. It gives the ceramic boat its strong properties. It handles tough industrial jobs well.

Why choose alumina ceramic for this part?

Alumina ceramic handles high heat very well. It resists chemical attacks strongly. It wears down slowly over time. It keeps its shape under stress. These traits make it reliable for demanding processes like semiconductor work.

Where do people use these high purity ceramic boats?

They are common in electronics manufacturing. They carry silicon wafers during high-temperature steps. Furnaces and diffusion processes use them often. They are also found in labs and other thermal processing equipment needing clean, stable carriers.

How tough is this alumina boat?

It is very hard and strong. It handles temperatures over 1500°C easily. Sudden temperature changes don’t crack it easily. It resists most acids and alkalis. It lasts much longer than metal parts in harsh conditions.

Can I get a custom size or shape?

Yes. We make custom ceramic boats. Tell us your exact requirements. We adjust the size, shape, and specific features. We ensure it meets your process needs perfectly.

(99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Ceramic Laboratory Crucible Boat Made from Alumina Cement

C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

High Temperature Alumina Corundum Ceramic Boat for Laboratory Furnace

Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible

99% High Alumina Ceramic Crucible Cylinder Al2O3 Alumina Combustion Boat With Lid , Rectangle Alumina Ceramic Boats Crucible