Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

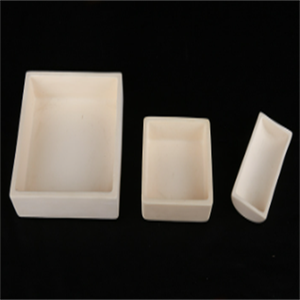

Overview of 99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts

99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of 99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts)

Specifications of 99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts

These ceramic watercraft boxes are developed tough. They take care of intense warmth inside kilns. Made from 99% pure alumina (Al2O3), they withstand extreme temperature levels. This high pureness is crucial. It ensures the sagger remains stable shooting porcelains. It won’t warp or split quickly under warm stress and anxiety.

Mullite and cordierite are additionally in the mix. These refractory materials enhance efficiency. Mullite includes strength at high heat. Cordierite aids with thermal shock resistance. Sudden temperature level changes are much less most likely to break the sagger. This combination develops a reputable container.

The major task is protecting ceramic parts during shooting. The sagger shields pieces from direct fire get in touch with. It prevents ash or debris from damaging surfaces. This maintains lusters tidy and surfaces smooth. Regular outcomes are much easier to accomplish. You obtain less defects in your fired ceramics.

Sturdiness is a significant plus. These watercraft boxes last many firing cycles. They withstand put on from duplicated heating and cooling. You conserve money changing them less typically. They endure aggressive kiln atmospheres also. Chemical reactions throughout shooting will not deteriorate them swiftly.

These alumina saggers benefit numerous porcelains. They support floor tiles, insulators, technical components. Their design promotes even warm distribution. Parts fire consistently inside the box. Filling multiple items is straightforward. The watercraft shape makes the most of kiln area efficiently. Performance gets an increase.

(99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts)

Applications of 99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts

99% alumina ceramic boat boxes deal with high warm very well. They work inside kilns shooting ceramic components. These boxes protect fragile products during extreme shooting cycles. The material withstands temperatures far past regular ceramics. This avoids warping and breaking. You obtain regular results batch after batch.

This high Al2O3 material offers superb chemical security. It withstands reactions with lusters or other materials inside the kiln. Contamination risks go down considerably. Your discharged items remain pure and clean. This is essential for delicate electronics parts or accuracy technical ceramics.

Mullite and cordierite variations use solid alternatives. Mullite gives wonderful thermal shock resistance. It deals with fast temperature adjustments without damaging. Cordierite excels in lower thermal expansion. It decreases stress throughout cooling and heating stages. Both products provide trusted efficiency.

These saggar boxes last a lot longer than less expensive options. They resist put on from repeated kiln use. You conserve money with time requiring less replacements. Much less downtime for upkeep takes place. Manufacturing performance boosts.

Durable construction avoids drooping under heavy lots. Your ceramic components stay completely located inside the kiln. Firing problems lower. Yield prices boost. Quality assurance becomes much easier. Packages offer crucial security for beneficial work.

They serve several industries well. Electronic devices manufacturers utilize them for firing substratums and insulators. Technical ceramics manufacturers rely upon them for facility components. Traditional potters locate them helpful for high-value items. Any type of application requiring tidy, high-temperature support advantages.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts

What material is this ceramic boat box made from?

It’s mostly alumina. The exact amount is 99%. This high alumina level makes it very strong. The box also contains mullite and cordierite. These materials boost its heat resistance and toughness. This combination handles extreme kiln conditions well.

How hot can this ceramic boat box get?

It handles very high temperatures. You can safely use it up to 1700°C. This is hot enough for most ceramic firing jobs. It stays stable and doesn’t warp or crack easily at these heats. Its performance is reliable under intense thermal stress.

Will chemicals damage the box?

It resists most chemicals well. Acids and alkalis generally don’t harm it. This is important for glaze firing. Glaze materials can be corrosive. The box won’t react or contaminate your ceramic parts. It protects your work during firing.

How long does this ceramic boat box last?

Lifespan depends on your use. How hot you fire, how fast you heat and cool, the weight of your parts – these factors matter. Using it correctly, it lasts much longer than cheaper options. Its high alumina content means it degrades slowly. Expect many firing cycles.

How do I clean this ceramic boat box?

Cleaning is simple after firing. Let the box cool down completely first. Then, brush off any loose debris. Stubborn residue might need gentle wiping. Use a soft, damp cloth. Avoid harsh chemicals or rough scrubbing. Proper cleaning prevents buildup affecting future firings.

(99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Rectangle Alumina Ceramic Boat 100*30*20mm for Tube Furnace / Alumina Crucible

Alumina Crucible Boat Combustion Boat Machinable Ceramics

Lab Alumina Ceramic Boat Crucible for Sulphur Determination Device

High 99 Al2o3 Zirconia Ceramic Alumina Boat With Lid

Lab High Purity 99% Al2O3 Rectangle Alumina Ceramic Boat 1700 C for Metal Casting and Ceramic Sample Preparation