Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

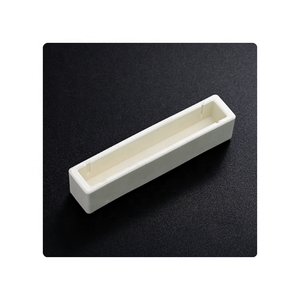

Overview of Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry

Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry)

Specifications of Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry

These Al2O3 Alumina Refractory Ceramic Boats and Trays are essential devices for jewelry job. They handle the extreme warmth discovered in kilns and furnaces. Alumina ceramic is the primary product. It is very pure aluminum oxide. High purity levels like 99% Al2O3 prevail. This pureness ensures reliable performance. It avoids contamination of precious metals.

The crucial toughness is unbelievable warmth resistance. These things hold up against temperature levels quickly over 1700 ° C (3100 ° F). This is much hotter than most jewelry procedures call for. They maintain their form and strength also at these extremes. Thermal shock resistance is another major advantage. The boats and trays handle unexpected temperature level changes well. Going from space temperature to high heat causes much less fracturing threat. This durability issues for repeated use.

Chemical inertness is important. The alumina ceramic does not respond with liquified metals or fluxes. It protects your precious jewelry items during fatigue cycles. This avoids unwanted reactions. You obtain cleaner spreading outcomes. The product is extremely tough. It stands up to abrasion and use in time. This durability indicates the watercrafts and trays last longer. You get great value.

These ceramic products come in different typical shapes and sizes. Little watercrafts hold private items. Bigger trays manage several products at the same time. Their style promotes also warmth circulation. This consistency is crucial for successful fatigue and casting. Correct handling is essential. Avoid impacts or declines. The material is strong yet can be breakable like most porcelains. Care makes sure a long service life.

Jewelers rely upon them for lost wax spreading fatigue. They securely hold wax patterns inside high-temperature kilns. They are additionally used for annealing or sintering steel parts. Labs find them important for high-heat example processing. Their security and integrity support precision job.

(Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry)

Applications of Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry

Alumina refractory ceramic watercrafts and trays are vital tools for jewelry experts. These parts are made from high-purity aluminum oxide. They endure severe temperatures. Jewelers utilize them daily for shooting and sintering rare-earth elements and rocks. The watercrafts and trays hold items safely inside kilns and furnaces.

Warm resistance is their main benefit. They easily deal with temperatures going beyond 1750 ° C. This is crucial for processes like enameling, casting, and annealing. Steel containers can not match this performance. Steel melts or contaminates the operate at high warm. Alumina porcelains stop this issue. They maintain your materials pure.

Resilience issues greatly. These ceramics are incredibly difficult. They withstand thermal shock well. Abrupt temperature level modifications won’t crack them quickly. This toughness indicates they last a long time. You get numerous uses from each watercraft or tray. This conserves cash over time. You change them less usually.

Chemical inertness is an additional vital benefit. Alumina does not react with liquified metals, enamels, or fluxes. It won’t stick to your precious jewelry pieces. Your job releases easily after firing. No unwanted deposits continue to be. This ensures constant, high-quality outcomes every single time.

Different shapes and sizes are readily available. Little watercrafts suit little items like rings or searchings for. Larger trays handle bigger products or several pieces. Picking the ideal dimension enhances performance. You optimize kiln room. You ensure even heat distribution. This brings about much better outcomes.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry

What are these boats and trays made of?

They are made from Al2O3 alumina. This is a special ceramic. It handles very high heat well. That makes it perfect for jewelry work.

How hot can these items get?

They withstand temperatures up to 1800°C (3272°F). This is very hot. You can melt most metals used in jewelry. Never exceed this limit. It can damage the boat or tray.

Will they crack from sudden temperature changes?

Alumina handles thermal shock well. It resists cracking when heated or cooled quickly. This is important for jewelry kilns. You need to put items in and take them out safely. Still, avoid extreme, rapid changes when possible.

Are they damaged by chemicals?

Alumina is highly resistant to chemicals. Fluxes, like borax, won’t eat into the material. Metal residues won’t stick badly. This keeps the boats and trays clean longer. It makes them last.

How do I clean them?

Cleaning is simple. Let the item cool completely first. Remove any leftover metal bits gently. Use a soft brush or a damp cloth. Avoid harsh scrubbing. Never use strong acids. They might damage the surface over time.

(Al2o3 Alumina Refractory Ceramic Combustion Boats and Trays for Jewelry)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Alumina Ceramic Boat Crucible With Hole for High Temperature Heat Treatment Melting

Laboratory Molten Metal Alumina Boat Analysis 95 Al2O3 Ceramic Crucible

Al2O3 Alumina Combustion Boat With Lid , Rectangle Alumina Sagger Ceramic Boats Crucible

XTL Sintyron Laboratory Use High Temperature Resistant Square Ark Alumina Ceramics Corundum Boat Crucible with Lid Cover

Alumina Combustion Ceramic Boat for High Temperature Furnace