Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

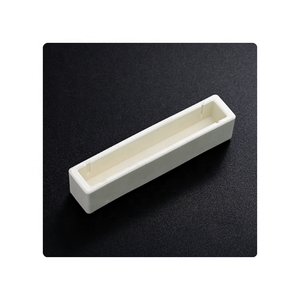

Overview of AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible

AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible)

Specifications of AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible

This ceramic watercraft crucible manages high temperatures. It’s made from AL2O3 cordierite ceramic. This material mixes alumina and cordierite. It gives outstanding thermal shock resistance. The crucible will not break quickly from abrupt temperature adjustments. It stands up to temperatures approximately 1650 ° C (3002 ° F). This makes it ideal for requiring melting work.

Chemical security is a crucial function. The crucible resists rust from several molten steels and salts. Common acids and alkalis won’t damage it conveniently. This inertness ensures your thaw remains pure. Contamination threats are low.

Its thermal growth rate is very reduced. Heat does not cause the material to increase a lot. This low development minimizes anxiety throughout heating or cooling. It adds substantially to the crucible’s lengthy life. Repeated home heating cycles will not weaken it swiftly.

Resilience is essential. This crucible is mechanically strong. It handles physical taking care of well. The smooth surface area stops product sticking. Cleaning up is basic after usage. You can use it lot of times. This conserves money over single-use options.

The boat form is useful. It holds materials firmly. It works well in tube heaters and kilns. Typical usages consist of thawing rare-earth elements like gold or silver. It’s good for sintering small components. Laboratories utilize it for sample prep work. Jewelers locate it trustworthy for spreading.

Different sizes are offered. Requirement dimensions exist. Customized sizes can be manufactured. Wall thickness affects warm transfer. Thicker wall surfaces use more thermal mass. Thinner wall surfaces warmth quicker. Choose based on your specific procedure needs.

This AL2O3 cordierite ceramic boat crucible offers dependable performance. It manages severe warmth. It stands up to thermal shock. It supplies chemical inertness. Its reduced growth makes sure long life. The boat style is convenient.

(AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible)

Applications of AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible

These ceramic boat crucibles take care of high warmth work reliably. AL2O3 cordierite ceramic makes them tough. They withstand extreme temperature levels quite possibly. This is vital for melting steels or handling materials. Many industries rely upon their security.

The material doesn’t split quickly under unexpected temperature level adjustments. This thermal shock resistance issues. Heater processes often warmth or trendy things quickly. Normal ceramics might break. These crucibles manage it.

They are chemically inert too. Harsh chemicals or reactive thaws do not harm them. This maintains your materials pure. Contamination is a large problem in labs and factories. These boats protect against that.

You see them utilized for sintering tiny parts. They hold parts constant during high warmth therapy. Electronic devices producing utilizes them typically. Semiconductor wafers require cautious handling. These ceramic watercrafts are excellent service providers.

Steel melting is an additional common job. They hold molten aluminum, copper, or comparable metals securely. The ceramic withstands the intense warmth. It does not react with the thaw.

Test preparation in labs utilizes these crucibles. They carry samples right into heating systems. Analytical screening requires tidy, secure containers. These supply that.

Their boat shape is practical. It offers a long, level surface. This holds several items or longer examples easily. Packing and dumping ends up being less complex.

Resilience is an essential advantage. They last much longer than more affordable choices. This saves money in time. Changing broken crucibles continuously lose time and cash money.

Handling calls for some care. Stay clear of abrupt influences. Thermal shock resistance is great, however extreme abuse can still cause damages. Adhere to the manufacturer’s heating and cooling prices.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible

Customers often ask about AL2O3 cordierite ceramic boat crucibles. Here are answers to common questions.

What is this crucible made from?

It uses a special mix of alumina (AL2O3) and cordierite ceramic. This mix makes the crucible very strong against heat shock. It handles sudden temperature changes well. This is important for melting metals.

How hot can it get?

These crucibles withstand very high temperatures. They work reliably up to about 1350 degrees Celsius. This makes them good for melting many metals. They stay stable even at these high heats.

What metals can I melt in it?

It works well for melting gold, silver, copper, and similar non-ferrous metals. Avoid melting iron or steel. These require much higher temperatures. The crucible might not be suitable for those.

How long does it last?

Lifespan varies. It depends on the temperatures you use. It depends on how often you heat and cool it. Handle it carefully. Avoid impacts. Proper care helps it last longer. It resists chemical wear well.

How do I care for it?

Let the crucible cool down slowly after use. Don’t put a hot crucible in cold water. This sudden cooling can cause cracks. Clean out leftover metal slag gently. Avoid using harsh tools. Store it in a dry, safe place. Protect it from knocks.

(AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

99% Alumina Boat Shape Ceramic Crucible with Hole or Not High Temperature Alumina Crucible

Alumina Zirconia Ceramic Plate Rods for Wire Wound Resistor Resistance Resistors Boat Welding and Cutting

50*20*20 mm Heat Resistance Square Laboratory Alumina Ceramic Boat Crucible

Alumina Crucible Boat Combustion Boat Machinable Ceramics