Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

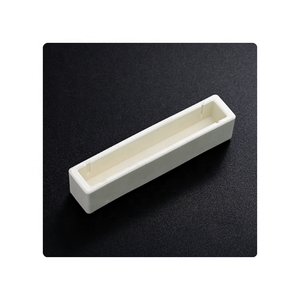

Overview of Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing

Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing)

Specifications of Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing

Alsint C799 Alumina Al2O3 Porcelain Combustion Watercraft Crucibles handle clay firing work. These boats are made from really pure alumina ceramic. The material is over 99% Al2O3. This high purity is essential. It provides the watercrafts outstanding high-temperature performance. They withstand temperature levels approximately 1800 ° C. This is important for shooting clay.

The boats stand up to thermal shock well. Unexpected temperature level adjustments happen during kiln loading and discharging. The boat will not break conveniently. It stays secure. This product is chemically inert. It won’t respond with clay products or changes. Your materials stay uncontaminated. The boat surface area is smooth. Lusters or various other products won’t stick. Cleansing is very easy after shooting.

These alumina boats are strong. They resist wear and abrasion. They last a long time despite repeated heating cycles. Standard sizes are readily available. Usual sizes fit lots of kiln shelves. The measurements are precise. Watercrafts hold examples securely. Measurements like size, width, and elevation are consistent. You understand the precise ability.

Making use of these boats makes clay shooting trustworthy. They transfer heat successfully to your clay pieces. This promotes even firing. The watercrafts preserve their shape under extreme warm. They won’t warp or sag. This secures your clay work. The material is thick. It has reduced porosity. This prevents gases or fluids from permeating. Your outcomes stay foreseeable.

These burning boats match numerous high-heat processes. They work well in kilns and heaters. They are suitable for sintering clay bodies. They are good for glaze testing. They manage binder fatigue phases. They handle calcination actions. Alsint C799 watercrafts supply a dependable remedy. They sustain consistent, top notch clay shooting results.

(Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing)

Applications of Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing

Alsint C799 Alumina Porcelain Combustion Watercraft Crucibles are crucial for shooting clay. These crucibles are made from extremely pure Al2O3 ceramic. This product manages severe heat exceptionally well. Clay firing typically requires really heats. This crucible stays strong and dependable under those problems.

Thermal shock resistance is a major advantage. Kilns heat up and cool lot of times. Abrupt temperature modifications can break weak materials. This Al2O3 ceramic crucible resists cracking. It lasts with many shooting cycles. This saves cash gradually.

Securing clay items is important. The crucible functions as an obstacle. It guards your work from straight fire contact and kiln debris. This avoids damages and undesirable marks. Cleaner results are attained regularly.

Luster firing presents specific challenges. Lusters can thaw and engage with surface areas. This Al2O3 ceramic is extremely inert. It stands up to chemical reactions with liquified lusters. Your glaze colors remain true. Crucible contamination of your work is lessened.

Managing fragile pieces is easier. Area fragile greenware or intricate sculptures safely inside the watercraft. The boat supports the piece during firing. It protects against deforming or plunging. Moving things in and out of the kiln is additionally much safer.

These boats are really resilient. They stand up to wear and abrasion. They tolerate high temperatures without breaking down. Recycling the boat sometimes is conventional practice. This decreases waste and decreases expenses dramatically. Correct treatment guarantees a lengthy service life.

The smooth surface area finish is very important. Glaze trickles or clay residue will not stick badly. Cleaning the watercraft in between usages is uncomplicated. This keeps performance and health. Consistent outcomes are less complicated to accomplish.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing

Here are key questions about the Alsint C799 Alumina Ceramic Combustion Boat Crucible for clay firing:

What is this crucible made from?

It is pure alumina ceramic, Al2O3. This material is very hard. It handles extreme heat well. This is vital for firing clay safely.

How hot can it get?

It withstands temperatures up to 1800°C (3272°F). This covers most clay and glaze firing needs. Check your kiln’s maximum temperature first. Stay below the crucible’s limit.

Can I use it more than once?

Yes, it is reusable. Its high purity and density make it strong. It resists wear over many firings. Inspect it for cracks before each use. Handle it carefully.

Will glazes damage it?

Alumina is chemically inert. Glaze materials usually don’t stick or react with it. Clean any spills after firing. It resists most fluxes found in glazes. Glaze won’t eat it.

Can I heat it up fast?

Avoid sudden temperature changes. Alumina handles thermal shock better than many ceramics. But rapid heating or cooling can cause cracks. Heat and cool it gradually. This protects it.

How do I clean it?

Let it cool completely first. Remove debris gently. Use a soft brush or cloth. Stubborn residue might need soaking in water or a mild acid solution. Avoid harsh abrasives. They can scratch the surface.

(Alsint C799 Alumina Al2O3 Ceramic Combustion Boat Crucible for Clay Firing)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

Industrial High Purity 99 Alumina Ceramic Crucible Boat, Tube, Ball

95% 99% Alumina Crucible Boat Al2O3 Ceramic Boat

95% ~ 99% AL2O3 Aluminum Oxide Alumina Ceramic Crucible With Corrosion Resistance/ceramic boat

Factory Custom High Purity 99% Al2o3 Ceramic Crucible Rectangular Alumina Ceramic Boat and Crucible Moulded Processing Service