Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

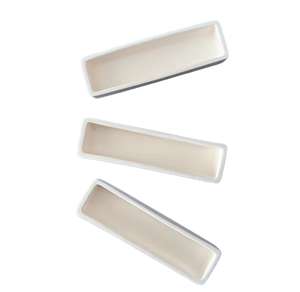

Overview of Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products

Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products )

Specifications of Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products

Alumina ceramic crucibles and boats are made from light weight aluminum oxide (Al2O3). This product is really difficult and resilient. It deals with high heat exceptionally well. These containers resist temperatures as much as 1750 ° C quickly. Brief bursts of also higher warm are feasible. They are ideal for demanding furnace work.

Chemical resistance is a major advantage. Alumina ceramic does not respond with a lot of acids and alkalis. It stays steady in rough chemical environments. This makes it dependable for melting, calcining, and evaluating examples. You avoid contamination of your products.

These items are mechanically solid. They stand up to breaking under thermal stress. Abrupt temperature adjustments are less bothersome. Good thermal shock resistance implies longer life. You get more usage from each crucible or watercraft.

Thermal conductivity is reduced. Warm moves slowly via the ceramic. This allows for regulated heating and cooling. Temperature slopes inside your example are minimized. Consistent outcomes are simpler to achieve.

The surface area is extremely smooth. Polishing is frequently used. This smoothness avoids material sticking. Cleaning after use is easier. Regular performance is maintained batch after batch.

Different purity levels exist. Usual grades are 95% and 99% Al2O3. Greater purity offers better efficiency. It endures greater temperatures and more corrosive products. Select the pureness based on your particular demands.

Numerous shapes and sizes are readily available. Crucibles come in tall or low forms. Boats are long and open. Requirement dimensions match most lab heating systems. Customized designs are additionally feasible for special applications.

These alumina containers are vital tools. They operate in research laboratories and industrial setups. Usual usages include metal melting, powder handling, and materials screening. They are vital for quality assurance and research.

(Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products )

Applications of Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products

Alumina ceramic crucibles and watercrafts are crucial devices for high temperature job. They take care of extreme warmth very well. Alumina (Al2O3) ceramic is incredibly steady. It withstands temperature levels reaching 1800 ° C or greater. This makes these containers perfect for melting metals like gold, silver, platinum, and various other alloys. Jewelers and steel wheels count on them daily.

These ceramic products are chemically inert. They do not react easily with most materials. Strong acids, strong bases, and responsive molten materials typically don’t affect them. This inertness is essential. It maintains your example pure. It prevents contamination during melting or evaluation. Labs testing materials require this integrity.

Alumina crucibles and boats resist thermal shock. They handle unexpected temperature modifications well. Relocating a crucible from a warm heating system to a cooler area is more secure. This minimizes cracking threat. It enhances the product’s lifespan. Individuals save cash in time.

The pureness of the alumina matters. High pureness alumina (99% or more) offers the most effective performance. It provides maximum temperature level resistance. It offers excellent chemical stability. Reduced purity qualities are less expensive. They work well for less requiring jobs. You choose based upon your specific warmth and chemical needs.

These porcelains are widely utilized. They are common in research study labs. Universities use them for product experiments. Industrial settings depend upon them for processing powders. The semiconductor sector utilizes high-purity alumina boats for wafer handling. Glassmakers use them for frit melting. Catalysis research study calls for steady containers. Alumina supplies that stability.

These containers come in several sizes and shapes. Crucibles are deep cups. Boats are superficial trays. You select the kind element that fits your heating system and process. Alumina ceramic products are strong and sturdy. They withstand repeated high-temperature cycles. This sturdiness makes them a useful financial investment.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products

Here are 5 common questions about Alumina (Al2O3) Ceramic Crucibles/Boat Containers:

What’s the highest temperature this crucible handles? Alumina crucibles manage very high heat. They typically work well up to 1700°C (3092°F). Some special grades go even higher. Always check the exact rating for your specific crucible. Exceeding the limit risks damage.

Will chemicals attack the alumina? Alumina resists many chemicals well. It handles most acids and molten salts fine. But avoid strong alkalis like sodium hydroxide. They can corrode the material over time. Know what chemicals you use.

Can it handle quick temperature changes? Alumina has good thermal shock resistance. It copes with moderate heating and cooling changes. Sudden, extreme temperature swings might cause cracking. Heat and cool it gradually when possible.

How do I clean it after use? Cleaning depends on the residue. Often, simple mechanical removal works. Use a brush or scraper carefully. For tougher residues, try soaking in acid or solvent. Check what’s safe for your crucible. Avoid abrasive scrubs that scratch the surface.

How long will an alumina crucible last? Lifespan varies a lot. It depends on temperature, chemicals used, and handling. Gentle use at lower temps makes it last long. Harsh conditions like high heat or corrosive materials shorten life. Inspect it regularly for cracks or wear. Replace it when damaged.

(Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products )

REQUEST A QUOTE

RELATED PRODUCTS

Lab Combustion Boat Alumina Ceramic Boat

Alumina Ceramic Crucible Cupel Boat Sample Holder for Laboratory and Research Purposes

Alumina Zirconia Ceramic Plate Rods for Wire Wound Resistor Resistance Resistors Boat Welding and Cutting

High Temperature Trapezoidal Shape Ceramic Alumina Boat Crucible for Melting Furnace

High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates