Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

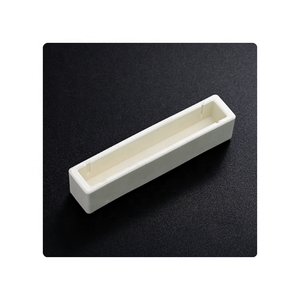

Overview of Alumina Combustion Ceramic Boat for High Temperature Furnace

Alumina Combustion Ceramic Boat for High Temperature Furnace is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Alumina Combustion Ceramic Boat for High Temperature Furnace

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Alumina Combustion Ceramic Boat for High Temperature Furnace)

Specifications of Alumina Combustion Ceramic Boat for High Temperature Furnace

Alumina burning ceramic watercrafts deal with intense heater warmth reliably. These boats are made from high pureness alumina ceramic product. This material endures temperatures approximately 1800 ° C conveniently. It maintains its shape even under extreme thermal stress and anxiety. The watercrafts stand up to abrupt temperature modifications well. This thermal shock resistance prevents cracking during rapid heating or cooling cycles.

Chemical stability is an additional key attribute. Alumina ceramic strongly resists strike from acids, bases, and molten salts. This inertness safeguards your samples or products inside the watercraft. It avoids contamination during essential high temperature processes. The boats supply exceptional electric insulation residential properties as well. This is vital for lots of furnace applications.

Surface area coating is smooth and thick. This reduces gas absorption or reaction with the watercraft surface area. It cleans much easier after usage. You locate these watercrafts in different conventional shapes and sizes. Typical forms consist of rectangle-shaped, semi-circular, and multi-channel styles. Dimensions usually range from little boats holding a couple of grams to larger ones for bigger lots. Lots capacity depends on the watercraft size and wall surface density. Thicker walls support much heavier products yet heat slower. Thinner walls heat quicker yet hold much less weight.

Alumina watercrafts are dimensionally stable. They do not warp or reduce dramatically at high temperatures. This ensures consistent positioning and processing of your products. Lengthy service life is expected with appropriate handling. They resist wear and disintegration successfully. Alumina burning boats provide a steady, inert platform for requiring heating system job. They are important devices for sintering, calcination, annealing, and various other high warmth treatments.

(Alumina Combustion Ceramic Boat for High Temperature Furnace)

Applications of Alumina Combustion Ceramic Boat for High Temperature Furnace

Alumina combustion ceramic boats are essential devices for high temperature heater job. These little tray-like holders take care of examples during intense home heating procedures. They are made from really pure light weight aluminum oxide ceramic. This material provides superior performance where extreme warm is included.

Alumina ceramic withstands temperature levels well past 1500 ° C conveniently. It doesn’t thaw or flaw under these problems. This stability is important for regular results. The material additionally handles rapid heating and cooling cycles well. It will not break conveniently from unexpected temperature level adjustments. This thermal shock resistance makes it trustworthy for repeated heater usage.

Chemical inertness is another significant advantage. Alumina ceramic does not react with many chemicals or gases existing in furnaces. This protects against contamination of your samples. It also makes sure the watercraft itself does not degrade rapidly. You prevent undesirable reactions ruining your experiment or production batch.

These watercrafts are best for sintering ceramic or steel powders. They hold the powder safely while it bonds under high heat. They are likewise optimal for calcination processes, repeling unpredictable components from products. Ash content screening frequently uses them as well. They safely hold product while it burns entirely. Catalyst testing and different heat therapy steps count on these long lasting sample owners.

Utilizing an alumina combustion boat is simple. You simply position your sample material inside it. After that you position the watercraft meticulously within the furnace warm area. Ensure it sits firmly on the heater rack or sustains. Manage the watercraft carefully when hot or cold. Prevent sudden impacts which might trigger chipping. Clean it thoroughly after each use to stop cross-contamination. Correct care prolongs its life span significantly.

Alumina boats use a clear benefit over cheaper options like quartz or porcelain. They last a lot longer under rough furnace conditions. Their purity warranties sample stability. Their durability reduces unanticipated failings. Investing in high quality alumina boats saves money and time long-lasting. They offer reliable efficiency for demanding high warm applications.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Combustion Ceramic Boat for High Temperature Furnace

What is an alumina combustion ceramic boat? It’s a container made from high-purity alumina ceramic. You use it to hold samples in high-temperature furnaces. The material doesn’t react with most chemicals. This keeps your samples clean during heating. What temperature can it handle? These boats withstand up to 1700 degrees Celsius. They stay stable without cracking or warping. This makes them perfect for sintering or annealing. How do you clean it? Let the boat cool completely first. Rinse it with water or mild detergent. Use a soft brush for stubborn residue. Avoid harsh chemicals. Dry it thoroughly before reuse. Why pick alumina over other materials? Alumina resists extreme heat better than metals. It doesn’t corrode or release fumes. Plus, it lasts longer than cheaper alternatives. This saves money over time. How long will it last? With careful use, it serves for years. Don’t expose it to rapid temperature swings. Handle it gently to avoid chips. Check for cracks before each use. Replace it if damage appears.

(Alumina Combustion Ceramic Boat for High Temperature Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

99% Alumina Boat Shape Ceramic Crucible with Hole or Not High Temperature Alumina Crucible

Alumina Crucible Boat Combustion Boat Machinable Ceramics

99% Alumina Ceramic Boat Box High Al2O3 Refractory Mullite Cordierite Saggar for Kiln Firing Ceramic Parts

Corundum Crucible Ceramic Square Alumina Crucible Boat Cylinder Industrial Ceramic Substrate Plates Customizable Cutting Service

Rectangle Alumina Ceramic Boats Crucible