Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

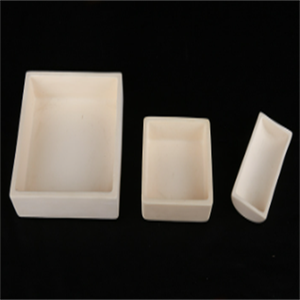

Overview of Alumina Crucible Boat Combustion Boat Machinable Ceramics

Alumina Crucible Boat Combustion Boat Machinable Ceramics is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Alumina Crucible Boat Combustion Boat Machinable Ceramics

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

( Alumina Crucible Boat Combustion Boat Machinable Ceramics)

Specifications of Alumina Crucible Boat Combustion Boat Machinable Ceramics

Alumina crucible boats are necessary tools for high-temperature jobs. They’re made from high-purity light weight aluminum oxide ceramic. This product offers outstanding performance. The purity degree is commonly 99.5% or greater. This guarantees chemical security and resistance. These boats deal with extreme warm effectively. They hold up against continual use at 1800 degrees Celsius. They manage short bursts also hotter. Thermal shock resistance is a major benefit. They manage abrupt temperature level changes without breaking. This is important for numerous home heating and cooling cycles.

Mechanical stamina is high. The ceramic is difficult and sturdy. It stands up to wear and scratches properly. This strength implies the watercrafts last much longer. They endure rough handling much better than some materials. The form is typically rectangular or boat-like. This style holds samples firmly during home heating. Various sizes exist. Typical sizes vary from 50mm to 200mm. Widths and midsts vary to suit various example quantities. Personalized dimensions are frequently feasible.

Chemical inertness is crucial. Alumina does not respond with the majority of substances. It will not contaminate your examples. Acids, bases, and molten salts normally don’t influence it. This makes the watercrafts best for analytical chemistry. They excel in sample prep work like ashing or calcination. They’re utilized in tube heating systems frequently. Semiconductor processing relies on them. Powder metallurgy applications use them too. Glaze testing is one more usual area. They supply a secure, non-reactive container. You obtain constant outcomes set after batch. Their smooth surface is very easy to clean. Debris does not stick stubbornly. This streamlines maintenance between uses.

( Alumina Crucible Boat Combustion Boat Machinable Ceramics)

Applications of Alumina Crucible Boat Combustion Boat Machinable Ceramics

Alumina crucible boats are important devices in many requiring setups. They take care of extremely heats conveniently. This makes them best for laboratory work. Drug stores use them to melt examples safely. They work well for ashing tests too. Materials stay pure inside them. They resist chemical attack efficiently. You can warm them repetitively without damage.

Industrial refines rely on these crucibles. They are vital for sintering ceramics. Precise shooting requires secure containers. Alumina watercrafts give that stability. Metal powder handling uses them frequently. They hold powders throughout warm therapy. Glaze firing in ceramic relies upon them. They endure the intense kiln heat continually.

Semiconductor manufacturing needs severe pureness. Alumina boats satisfy this strict demand. They carry silicon wafers with furnaces cleanly. No contamination risks exist. Their machinable nature is a huge benefit. Manufacturing facilities shape them right into custom styles swiftly. Specific furnace measurements require precise fits. Personalized boats address this problem quickly.

Drug study uses these crucibles greatly. Evaluating drug substances requires inert vessels. Alumina provides best inertness. Thermal evaluation tools incorporate them efficiently. They provide trustworthy results each time. Their resilience conserves money long term. Labs prevent consistent replacements.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Crucible Boat Combustion Boat Machinable Ceramics

Alumina Crucible Boat FAQs

What material is this boat made from?

It’s high-purity alumina ceramic. This material is very strong. It handles extreme heat well. It also resists chemical attack effectively.

How hot can it get?

This boat handles temperatures up to 1750°C (3182°F) continuously. Short bursts can go even higher. It won’t melt or deform at these temperatures. It stays stable.

Will chemicals damage it?

Alumina resists most acids and alkalis very well. Strong acids like hydrofluoric or phosphoric acid might damage it. Molten metals can also be a problem sometimes. Check compatibility for your specific chemicals.

Can I get a custom shape?

Yes. These ceramics are machinable before final firing. We can make custom sizes or shapes. Tell us your exact requirements. We’ll see if it’s possible.

How do I handle it safely?

Alumina is strong but brittle. Avoid impacts or drops. Don’t subject it to rapid temperature changes. Heat it up slowly. Cool it down slowly too. This prevents cracks. Always let it cool completely before handling. Use tongs when hot. Clean it carefully to avoid scratches.

( Alumina Crucible Boat Combustion Boat Machinable Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Alumina Ceramic Cylinder Part 99% Al2O3 Alumina Combustion Boat , Rectangle Alumina Ceramic Boats Crucible

Alumina Sagger Box Alumina Ceramic Boat

Al2o3 Alumina Ceramic Arc Boat Cordierite Ceramic Evaporation Boat Crucible

Lab Alumina Ceramic Boat Crucible for Sulphur Determination Device

High Temperature Alumina Corundum Ceramic Boat for Laboratory Furnace