Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

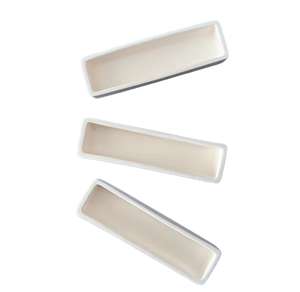

Overview of C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services)

Specifications of C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

The C795 burning watercraft deals with severe heat up to 1400 ° C. It is developed from 95% aluminum oxide alumina ceramic. This product offers high stamina and superb thermal stability. It stands up to chemical deterioration and thermal shock. The boat operates in industrial furnaces and laboratory setups. It securely holds examples throughout burning or evaluation. Requirement dimensions are 77mm size, 10mm width, 8mm height. Personalized sizes are offered. The form features a level base and bent top. This style stops spills and alleviates handling. Alumina ceramic purity makes certain consistent efficiency. It withstands repeated heating cycles without degrading. The product remains non-reactive with most compounds. It preserves architectural stability under tension. Customized reducing solutions adjust the ceramic to your demands. We shape parts for particular commercial applications. Accuracy cutting usages progressed techniques like diamond devices. This ensures precise dimensions and smooth edges. We produce burning watercrafts wholesale or little batches. Quality checks confirm each piece prior to delivery. The boats await prompt usage. They call for minimal upkeep. They clean conveniently after experiments. We maintain common dimensions in supply. Unique orders have fast turnaround times. International delivery alternatives cover most areas. The C795 matches fields like metallurgy and materials screening. It delivers reliability in high-temperature procedures. We focus on sturdy industrial options. Get in touch with us for customized ceramic parts.

(C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services)

Applications of C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

The C795 ceramic burning watercraft manages severe heat. It operates in heaters approximately 1400 ° C. This watercraft is made from 95% light weight aluminum oxide (Al2O3). Alumina ceramic is extremely challenging. It stands up to chemical assaults well. Acids and antacid won’t harm it easily. This product maintains its form under heats. It will not warp or crack unexpectedly. Thermal shock resistance is solid. The boat surface area is very smooth. Samples will not stick to it. Contamination risks are low. These homes make it trustworthy.

You utilize this boat in laboratories and market. It’s ideal for sample analysis. Usual work include ash screening. It helps thermogravimetric analysis (TGA). The boat holds examples throughout home heating. It benefits sintering little parts. High-temperature calcination utilizes it. The watercraft endures harsh furnace atmospheres. Oxidizing and lowering gases are fine. It does well in air or inert gas.

This combustion watercraft can be found in standard dimensions. Custom sizes are offered as well. We offer precise custom reducing solutions. Required a specific form? We can make it. Need an unique measurement? We can cut it. Our machining takes care of alumina ceramic properly. We supply parts ready for your heating system. Our solution sustains your precise needs. Obtain burning boats created your process. We focus on long lasting, high-performance ceramic components. Our items fulfill industrial demands.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

C795 Alumina Ceramic Combustion Boats FAQ

What’s the maximum temperature for this boat?

This combustion boat handles temperatures up to 1400°C. It’s made for intense furnace heat. You can use it reliably at that temperature.

Can I get a different size boat?

Yes. We offer custom cutting services. You can order boats in any size you need. Tell us your specific dimensions. We make it to fit.

Why is it 95% Aluminum Oxide?

95% Alumina (Al2O3) gives the best mix. It’s very strong. It resists heat shock well. It handles chemicals too. This grade works best for most furnace jobs.

How long does the boat last?

It lasts a long time. The material is very hard. It resists wear and chemicals. Don’t drop it though. Handle it with care for longest life.

What is the custom cutting service?

We cut the ceramic to your exact shape and size. You give us the specs. We machine the Alumina precisely. This is for special projects needing unique parts.

(C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services)

REQUEST A QUOTE

RELATED PRODUCTS

95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

Customized Shape and Size Alumina Ceramic Crucible Al2O3 Molten Metal Ceramic Boat

Lab Rectangular Thin Alumina Boat Crucible for Tube Furnace 80*10*10mm , Al2O3 Ceramic Boat

Customized Alumina Irregular Analysis Crucible Insulator Al2O3 Ceramic Boat

High Precision Ceramic High 99.7% Alumina Boat Crucible