Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

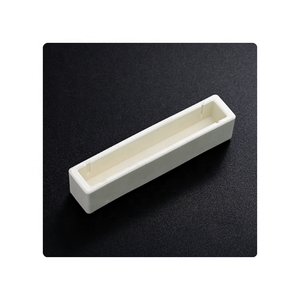

Overview of Ceramic Alumina Combustion Boats From HIGHBORN

Ceramic Alumina Combustion Boats From HIGHBORN is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Ceramic Alumina Combustion Boats From HIGHBORN

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Ceramic Alumina Combustion Boats From HIGHBORN)

Specifications of Ceramic Alumina Combustion Boats From HIGHBORN

Right here are the specs for HIGHBORN Porcelain Alumina Burning Boats. These watercrafts hold samples during high-temperature processes like ashing or calcining. They are made from high-purity alumina ceramic product. The alumina content is over 99%. This guarantees exceptional thermal security and chemical resistance.

The material density is high, over 3.8 g/cm SIX. This high thickness suggests the boats stand up to use well. They also deal with thermal shock much better than much less dense porcelains. You can use them continuously without breaking down promptly.

Optimum continuous operating temperature level is 1750 ° C(3182 ° F). Temporary spikes to 1800 ° C (3272 ° F) serve. Avoid long term direct exposure above 1750 ° C. The watercrafts heat up and cool gradually. This stops fracturing from unexpected temperature level modifications.

Chemical resistance is respectable. The alumina withstands attack from acids, bases, and molten salts. It will not pollute your examples. This makes it suitable for different logical procedures.

Standard sizes are offered. Usual dimensions consist of 50mm, 70mm, 90mm, and 100mm long. Widths array from 10mm to 30mm. Heights are generally 8mm to 15mm. Custom-made sizes are possible. Contact us for special requirements.

The watercrafts are vulnerable. Handle them carefully. Prevent effects or dropping them. Tidy them with proper solvents after use. Correct care prolongs their service life. They are reusable if dealt with correctly. This offers excellent long-term value.

(Ceramic Alumina Combustion Boats From HIGHBORN)

Applications of Ceramic Alumina Combustion Boats From HIGHBORN

Researchers and designers need trusted tools for high-temperature job. HIGHBORN ceramic alumina combustion watercrafts are built for precisely that. They are made from pure, state-of-the-art alumina ceramic. This product takes care of extreme warmth conveniently. These watercrafts are important devices in numerous laboratories and markets.

Analytical drug stores use them daily. They put samples inside for precise analysis. Usual tests consist of ash resolution and thermogravimetric analysis. The boats hold samples steady at really high temperatures. They make sure exact, repeatable results every time.

Product researchers rely on them too. They utilize the boats for sintering new materials. They likewise utilize them for calcining powders. The boats hold up against consistent heating and cooling down cycles. This makes them an economical, long-lasting solution.

Industrial processes demand durable parts. HIGHBORN burning watercrafts function well below. They are utilized in stimulant r & d. Quality control labs use them for example prep work. Production lines use them for small-scale heat therapies. Their longevity conserves money gradually.

These boats work in air or controlled gas setups. They resist chemical strike from most fluxes and samples. Their smooth surface prevents sample sticking. This makes clean-up easy and quick. Their form is maximized for effective heat transfer. Examples heat evenly inside the watercraft.

HIGHBORN ceramic alumina burning boats provide key benefits. They resist thermal shock incredibly well. They keep stamina even above 1700 ° C. Their low thermal development prevents fracturing. They are chemically inert for pure results. Their mechanical toughness resists damage. They offer regular performance set after set.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Alumina Combustion Boats From HIGHBORN

Here are 5 FAQs about HIGHBORN Ceramic Alumina Combustion Boats:

What’s the highest temperature these boats can take? HIGHBORN ceramic alumina boats handle 1750°C (3182°F) maximum. They stay strong at this heat. Going hotter risks damage. Always check your specific furnace limits.

What are these combustion boats used for? People use them in labs and industry. They hold samples for heating. Common jobs include ashing materials, sintering parts, calcining powders, and heat treating small items. They work well in tube furnaces and muffle furnaces.

How do I clean a used combustion boat? First, let the boat cool completely. Remove loose residue with a brush. Soak the boat in a suitable acid or solvent bath. Dilute hydrochloric acid often works. Rinse the boat very well with water afterwards. Dry it completely before reuse.

How long do these ceramic boats last? Lifespan depends on usage. Extreme temperatures, thermal shock, and harsh chemicals wear them down. Handle them carefully. Avoid sudden temperature changes. Inspect boats regularly for cracks or damage. Replace them when they show wear.

What’s the best way to handle these boats? Always use clean tongs. Never touch hot boats directly. Place boats on stable, heat-resistant trays during transport. Avoid dropping them. Protect them from impacts. Store them in a safe, dry place when not in use.

(Ceramic Alumina Combustion Boats From HIGHBORN)

REQUEST A QUOTE

RELATED PRODUCTS

99% Alumina Boat Shape Ceramic Crucible with Hole or Not High Temperature Alumina Crucible

Lab Combustion Boat Alumina Ceramic Boat

Rectangle Alumina Ceramic Boat 100*30*20mm for Tube Furnace / Alumina Crucible

99% Alumina Corundum Ceramic Boat Square Al2o3 Crucible for Furnace

High-Temperature Resistant Corundum Crucible Square Laboratory Ceramic Boat Alumina Crucible Square Laboratory Tube Furnace