Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

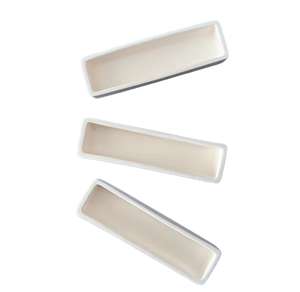

Overview of Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals

Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals)

Specifications of Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals

Alumina ceramic wafer boats and pedestals take care of rough lab atmospheres well. They withstand chemical strike efficiently. These components are made from high-purity alumina. This product is incredibly difficult. It supplies exceptional thermal stability too. Heats do not weaken it. These ceramics withstand rapid temperature level changes easily. They do not break under thermal shock. This is vital for semiconductor handling. Furnace procedures demand this reliability.

Deterioration resistance is their major strength. Acids do not harm them conveniently. Bases additionally cause little injury. Solid solvents leave them unaffected. This prevents sample contamination. Tidy handling problems are necessary. Metal components usually corrode and lose bits. Alumina porcelains stay inert. They keep your wafers risk-free. Item purity remains high.

These watercrafts hold silicon wafers firmly. They position wafers correctly during handling. Stands sustain wafers progressively. They make certain even home heating. Flatness is crucial for regular results. Alumina porcelains provide a secure platform. They keep specific dimensions. Warm won’t warp them. This dimensional stability is key. Refine repeatability depends on it.

Alumina porcelains last a very long time. They outlive steel options substantially. Their wear resistance is very good. Abrasion from handling doesn’t deteriorate them. This minimizes substitute prices. Lab downtime lowers. You save money over time. Upkeep needs are marginal. These porcelains are very easy to tidy. Rough cleaning agents will not damage them. Easy rinsing often is adequate.

They carry out reliably in CVD procedures. High-temperature diffusion steps are no worry. Oxidation heaters use them securely. These porcelains tolerate aggressive gases. They work well in vacuum cleaner conditions as well. Material stability remains undamaged. Process control improves. Return prices often increase.

(Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals)

Applications of Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals

Alumina ceramic wafer boats and stands manage silicon wafers in labs and manufacturing facilities. Their corrosion resistance is essential. These parts operate in very tough problems. They see heats and solid chemicals. This is common in making computer chips.

Thermal handling needs these porcelains. Annealing and diffusion steps take place inside heaters. Temperatures obtain very warm. Ordinary materials fall short right here. Alumina porcelains hold up. They resist the heat. They maintain their shape. Wafers remain safe.

Chemical vapor deposition makes use of these watercrafts and stands also. Responsive gases exist. These gases can eat away various other products. Alumina withstands this assault. It does not respond with many process gases. This keeps the components working longer. It avoids contamination.

Wet processing steps need corrosion resistance likewise. Boats and pedestals might go into acids or bases for cleaning. Solid etchants prevail. Alumina endures these fluids well. It does not break down rapidly. This indicates less replacement. It reduces expenses.

The product pureness is one more huge point. High-purity alumina has few impurities. These impurities could obtain onto wafers. They mess up the chips. Rust resistance helps keep purity. The material surface remains smooth. It does not launch bits. Tidy wafers are the outcome.

Resilience matters a whole lot. Labs run several cycles. Equipment runs frequently. Alumina watercrafts and pedestals last. They manage repeated heating and cooling. They stand up to chemical baths. This lowers downtime. It conserves cash gradually.

Accuracy is necessary. These components hold wafers specifically. They should not warp. Corrosion resistance helps stability. The material does not transform a lot. Measurements stay accurate. Wafer positioning remains proper. Return improves.

These ceramics operate in several devices. Heaters utilize them. CVD systems use them. Engrave stations utilize them. They are trustworthy parts. They take care of the work. They shield the useful wafers.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals

What are alumina ceramic wafer boats and pedestals? They hold silicon wafers during high-temperature processes like diffusion or annealing. These tools are made from high-purity alumina. Alumina is a ceramic material known for its strength and stability. It protects wafers from contamination.

Why choose alumina for corrosion resistance? Alumina handles harsh chemicals and extreme heat very well. Acids and bases don’t damage it easily. High temperatures in labs won’t warp or crack it. This keeps your wafers safe and processes reliable.

What benefits do these ceramic boats offer? They last much longer than metal or plastic alternatives. They resist wear and chemical attack. This saves money over time. They also prevent particle generation. Clean wafers mean better manufacturing results.

How should I clean alumina wafer boats? Use mild detergents or solvents like isopropyl alcohol. Avoid abrasive scrubbers or strong acids. Gentle cleaning prevents surface damage. Rinse thoroughly with deionized water after cleaning. Dry completely before reuse to avoid moisture issues.

Can these products be customized? Yes. Manufacturers adjust sizes and shapes to fit specific furnace tubes or tools. Custom slots or thicknesses are possible. This ensures compatibility with your lab equipment. Always provide exact dimensions for best results.

(Corrosion Resistance Alumina Lab Ceramic Wafer Boats&Pedestals)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Size 23ml 99% Al2o3 Crucible Cylinder Alumina Combustion Boat With Lid Rectangle Alumina Ceramic Boats Crucible

Al2O3 Alumina Combustion Boat with Lid , Rectangle Alumina Ceramic Boats Crucible

High Purity 99% Al203 Alumina Ceramic Evaporating Boat with Lid Industrial Lab Melting Crucible

Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat