Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

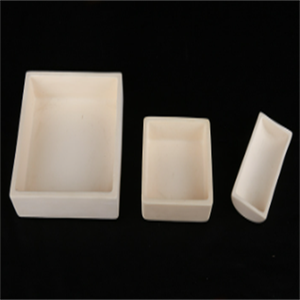

Overview of Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial

Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial)

Specifications of Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial

Customizable 99% Alumina Porcelain Components offer trustworthy performance for tough commercial tasks. Al2O3 insulator watercrafts are a common type. They are made from really pure alumina ceramic. This product is known for being strong and lasting a long time.

These parts manage severe warm very well. They function fine in temperatures approximately 1700 ° C. This makes them perfect for heating system job. They also shield power extremely effectively. You do not obtain electrical leak. This is crucial for electronic devices and electric applications.

Alumina ceramic is unbelievably tough. It stands up to wear and abrasion better than metal. Parts last longer in rough problems. This decreases downtime and replacement costs. The product is likewise chemically stable. It will not corrode or react with the majority of acids and alkalis. It works well in harsh chemical atmospheres.

We provide personalization. You can get specific sizes and shapes. We make components to fit your precise device or procedure. We can change dimensions, add holes, or develop one-of-a-kind styles. This makes sure the component does its task flawlessly in your configuration.

These ceramic watercrafts are extremely dense. They have reduced porosity. This stops liquids or gases from saturating with. It keeps efficiency constant. The product withstands thermal shock. It won’t fracture easily when temperatures alter quickly. This is essential for quick heating or cooling cycles.

Surface area surface choices are readily available. A smooth finish is basic. We can likewise give other finishes if needed. The high pureness alumina makes sure consistent residential properties. Every component satisfies rigorous high quality requirements. It supplies trustworthy insulation and thermal security batch after set.

These Al2O3 watercrafts are suitable for sintering, brazing, and heat dealing with. They are used in electronics, semiconductors, and metallurgy. They support components securely at heats.

(Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial)

Applications of Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial

Industrial refines need hard materials. Customizable 99% Alumina Ceramic (Al2O3) Insulator Watercrafts deliver. These components deal with extreme problems. Manufacturing facilities utilize them commonly.

Semiconductor making relies upon these watercrafts. They lug silicon wafers with high-temperature heaters. The alumina holds up against intense heat. It avoids contamination. This is vital for pure chips. Electronic devices manufacturing requires this reliability.

Warmth therapy heaters additionally make use of these ceramic watercrafts. They hold metal components during annealing or brazing. The boats stand up to thermal shock. Sudden temperature level modifications do not fracture them. This makes certain consistent part high quality. Assembly line avoid costly downtime.

Laboratories discover them vital for sintering. They hold samples requiring exact, high-temperature firing. The pure alumina doesn’t respond with most chemicals. Experiments stay unpolluted. Researchers trust the product’s stability.

The secret is modification. Factories need particular shapes and sizes. Possibly a distinct groove or hole pattern is called for. Manufacturers provide customized layouts. This makes sure an excellent fit for specialized machinery. Manufacturing runs smoothly.

Why pick 99% alumina? It offers outstanding electric insulation. This protects against dangerous shorts near heating elements. Its firmness withstands wear and abrasion. Parts last longer. Chemical resistance is outstanding versus acids and alkalis. Cleaning is simpler. Maintenance costs decrease. High-temperature security is unrivaled. These boats run dependably near 1700 ° C. They handle thermal biking well. Breakable crack is less most likely.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial

People often ask about our custom alumina ceramic insulator boats. Here are common questions:

What material is this? It’s 99% pure alumina ceramic, known as Al2O3. This material handles extreme heat well. It also stops electricity very effectively. That makes it perfect for tough industrial jobs.

Can you change the shape and size? Yes, absolutely. We specialize in custom designs. Tell us your exact needs. We make the insulator boat fit your machinery perfectly. This avoids problems with standard parts not working right.

How hot can it get? These parts withstand very high temperatures. They work reliably up to 1700°C (3092°F). They don’t melt or warp easily at normal furnace temperatures. This stability is crucial for consistent results.

Will chemicals damage it? Alumina ceramic resists most chemicals. Acids and alkalis generally don’t harm it. This resistance prevents corrosion. Your parts stay strong even in harsh chemical environments. This saves money over time.

How long does it last? These ceramic boats last a very long time. They resist wear, heat shock, and chemicals. This durability means less frequent replacements. You get reliable performance over many heating cycles.

(Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Custom 99% High Purity Al2O3 Alumina Combustion Boat Alumina Ceramic Part Rectangle Alumina Ceramic Boats Crucible

High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

Lab High Purity 99% Al2O3 Rectangle Alumina Ceramic Boat 1700 C for Metal Casting and Ceramic Sample Preparation

High Dielectric Strength Aluminum Oxide Alumina Al2O3 Ceramic Boat Crucible

99% High Alumina Ceramic Crucible Cylinder Al2O3 Alumina Combustion Boat With Lid , Rectangle Alumina Ceramic Boats Crucible