Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

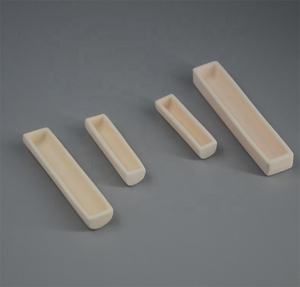

Overview of Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material

Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material)

Specifications of Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material

Good quality unglazed porcelain ceramic combustion watercrafts utilize premium alumina ceramic product. This material makes sure exceptional efficiency under severe warmth. Alumina ceramic withstands temperature levels as much as 1750 ° C. It does not thaw or warp at these degrees. Thermal shock resistance is another key feature. These boats manage abrupt temperature leaps without breaking. Chemical stability matters also. Alumina stands up to acids, alkalis, and various other responsive compounds. This stops sample contamination throughout experiments.

The watercrafts come unglazed for maximum reliability. Glaze can in some cases present impurities. The raw ceramic surface avoids this danger. It likewise offers a non-slip structure. Samples remain securely in position during heating. Toughness is a significant advantage. Alumina ceramic is really tough and thick. It resists wear and cracking. This durability means the watercrafts last much longer. They endure duplicated heating and cooling down cycles. Reusability conserves money with time.

Requirement sizes consist of sizes like 60mm, 90mm, and 120mm. Sizes and depths vary appropriately. Custom measurements are offered too. The boats have a simple boat form. This layout enables very easy example loading and ash elimination. Uniform wall density makes sure even warm distribution. This protects against locations that could alter test outcomes. Surface area surface is smooth however not brightened. This prevents any kind of unwanted responses with examples.

These burning boats work well in heating systems and kilns. They fit applications like ash screening, material evaluation, and heat therapies. Users in labs and markets trust them for constant results. Handling is uncomplicated. They are light-weight yet durable. Cleaning is basic after usage. Simply reject residue or use moderate solvents. Storage space needs no special conditions. Maintain them completely dry and devoid of influences.

(Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material)

Applications of Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material

Unglazed porcelain ceramic combustion watercrafts offer many important tasks. Alumina ceramic product makes these boats really solid. They handle extreme heat perfectly. Labs and factories count on them daily.

The key is the alumina ceramic. It’s pure and really dense. This offers the boats impressive heat resistance. They will not fracture or warp under high temperatures. This makes them risk-free for requiring work. They resist unexpected temperature level adjustments well as well. Thermal shock won’t damage them easily.

Chemical resistance is another significant advantage. Alumina ceramic fights off severe acids and alkalis. Examples stay unpolluted inside the watercraft. This pureness is essential for precise results. The unglazed surface area is essential. Lusters can melt or launch gases at high heat. Unglazed porcelain prevents this problem totally. Your examples remain pure.

These watercrafts see heavy use in analytical labs. They hold examples for ashing examinations perfectly. Finding the ash web content in materials needs trusted boats. Thermogravimetric evaluation (TGA) uses them constantly. The watercraft holds the sample while its weight changes with heat.

Industrial setups need them also. They are important for calcining powders. Producing pure oxides calls for secure containers. Sintering small parts often uses these boats. They take care of the extreme heating system warmth. Product screening laboratories depend upon them. Examining how substances respond to warmth requires a trustworthy boat. They are essential for catalyst studies. Observing driver habits under warm requires inert boats.

The form is simple and functional. It holds samples securely. Warm transfers equally inside the watercraft. This uniformity matters forever scientific research. Cleaning them is straightforward. Their sturdiness implies they last a long time. Labs save money changing them much less typically.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material

Here are 5 common questions about our high-quality unglazed porcelain ceramic combustion boats made with alumina ceramic material:

What exactly are these combustion boats?

These are small, boat-shaped containers. You use them in labs for heating solid samples. They go inside furnaces or kilns. They handle very hot fires safely.

Why use alumina ceramic?

Alumina ceramic is special. It withstands extremely high temperatures. Regular porcelain might crack. Alumina takes more heat without damage. It’s also very hard. This makes the boats last longer.

How hot can these boats get?

They handle intense heat well. The maximum continuous temperature is about 1750°C (3182°F). Short bursts can go slightly higher. Check the exact specs for your model. Always stay under the limit.

Will chemicals damage the boats?

Alumina ceramic is highly resistant. It doesn’t react with most acids or alkalis. Strong bases like molten sodium hydroxide might cause problems. Avoid those. The unglazed surface helps too. It stops chemicals from sticking easily.

How do I clean them after use?

Cleaning is simple. Let the boat cool down completely first. Brush off any loose residue. Soak it in a suitable acid or cleaning solution if needed. Rinse it well with water afterward. Dry it thoroughly before the next use. Avoid thermal shock from sudden temperature changes.

(Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Box Ceramic Boat Sagger

High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat

50*20*20 mm Heat Resistance Square Laboratory Alumina Ceramic Boat Crucible

High Temperature Pure Zirconia Crucible Alumina Rectangle Boat Ceramic Crucible

High Working Temperature Rectangle Arc Boat Various Shape Supply 99.6% Alumina Ceramic Crucible Lid Available for Laboratory