Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

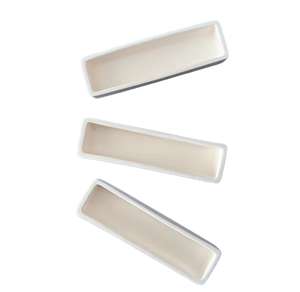

Overview of High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace

High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace)

Specifications of High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace

Our high pureness alumina ceramic crucible watercrafts are built difficult for your most popular heater tasks. They make use of over 99% pure Al2O3 ceramic. This high pureness issues. It straight gives the crucible its vital toughness. You get extreme temperature resistance. These watercrafts conveniently take care of continual consume to 1700 ° C (3092 ° F). They take care of brief ruptureds even higher.

Thermal shock is a major heating system difficulty. These watercrafts handle unexpected temperature swings well. They resist fracturing when heating up quick or cooling promptly. This dependability saves you time and money. You prevent frequent substitutes.

Chemical stability is another huge plus. The incredibly pure alumina stands up to strike. It won’t respond with many molten steels, slags, or fluxes. This maintains your materials pure. It stops contamination. You obtain accurate results.

The boats are available in lots of basic shapes and sizes. We provide rectangular shapes, watercrafts, tubes, and custom designs. Typical measurements consist of lengths from 50mm to 300mm. Widths array from 20mm to 100mm. Heights vary too. Tell us your requirements. We can likely make it.

Surface quality is exceptional. The alumina sinters largely. This produces a very smooth, non-porous finish. This level of smoothness aids. It quits product from sticking. It cleans much less complex. It likewise reduces wear with time.

Mechanical stamina is high. The thick alumina structure stands up to splitting. It takes on physical tension during loading and discharging. This toughness makes certain long life span. You obtain reliable efficiency run after run.

These crucible watercrafts work well in air or inert ambiences. They are ideal for sintering, annealing, and calcination. They fit metal melting and crystal development as well. Use them securely in oxidizing conditions. They do reliably under demanding thermal cycles.

(High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace)

Applications of High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace

These high purity alumina ceramic crucible watercrafts deal with severe warmth. Al2O3 material stays above 99%. This makes them incredibly secure. They withstand chemical assault well. Thermal shock resistance is solid. They work dependably in air or inert gas environments. Constant temperature levels reach 1800 ° C. Short ruptureds go also greater. This security is important for requiring procedures.

Metallurgists thaw and cast precious metals like gold and platinum inside them. The crucibles do not respond with the molten metal. They maintain the melt pure. Taste preparation for analysis utilizes these boats usually. They hold samples safely throughout extreme heating. No contamination occurs. This guarantees exact test outcomes.

Growing solitary crystals requires a steady container. These alumina boats supply that. They hold the molten resource product constant. Sintering sophisticated ceramics requires high warmth. These watercrafts bring components through the furnace. The alumina doesn’t communicate with the parts. Ceramic powder handling depends on them too. Powders are calcined inside the watercrafts. The boats make it through the warm cycle repeatedly.

Semiconductor producing usages ultra-clean processes. High pureness alumina watercrafts fulfill this need. They transport silicon wafers throughout annealing or diffusion. The material drops no bits. Glass labs discover them important. They melt and evaluate unique glasses. The watercrafts stand up to the destructive glass melt. Nuclear fuel research study utilizes them for handling radioactive products securely. The inert alumina contains the examples.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace

What’s this crucible boat made of?

It’s pure alumina ceramic. The material is over 99.5% Al2O3. This high purity ensures strength. It prevents contamination of your materials inside.

How hot can it get?

This crucible boat handles extreme heat. It withstands temperatures up to 1750°C (3182°F). It works reliably in air or inert atmospheres. Use it confidently in most high-temperature furnaces.

Will it crack from temperature changes?

Thermal shock resistance is excellent. The boat handles sudden heating or cooling. It resists cracking. Its dense structure prevents damage from rapid temperature shifts.

How do I clean it?

Cleaning is straightforward. Use acids like hydrochloric or nitric for residues. Use alkalis for other contaminants. Rinse thoroughly with water after cleaning. Avoid mechanical shock during handling.

What’s it best used for?

Its main use is high-temperature processing. Common applications include sintering, annealing, calcining. It’s ideal for handling powders, metals, ceramics. It works well in labs and industry.

(High Al2o3 Purity Alumina Ceramic Crucible Boat for High Temperature Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

High Temperature Resistant Square Alumina Ceramic Boat With Large Capacity

SINTYRON Unglazed Rectangular Alumina Ceramic Combustion Boat Laboratory Crucible for Melting

Al2O3 Alumina Ceramic Boat Crucible With Lid for Labs 60*30*15mm

Shenxing Ceramic 99% Alumina Ceramic Graphite Boat Rod Spacer Cushioning Spacer