Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

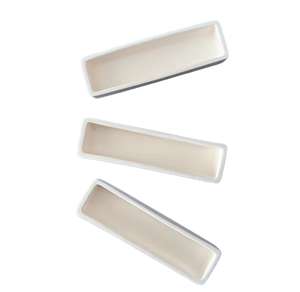

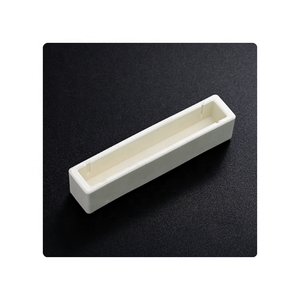

Overview of High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting)

Specifications of High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

These ceramic crucible watercrafts are made from high-grade 99% alumina (Al2O3). This high purity makes them incredibly hard versus heat and chemicals. They are vital devices for melting metals like gold, silver, and aluminum. You need reliable tools for these demanding work.

The major product is diamond. This is a really hard mineral. Its framework provides these crucible boats exceptional performance. They deal with extreme heat well. The optimum functioning temperature reaches 1750 ° C (3182 ° F). This is hot enough for a lot of precious metal melting jobs.

Toughness is an essential feature. These alumina watercrafts resist strike from many molten steels and changes. You will not see fast disintegration or contamination of your melt. This pureness matters for obtaining consistent results. It additionally means the watercrafts last longer under hard problems.

Thermal shock resistance is another large plus. The boats deal with rapid home heating and cooling cycles. You can heat them up swiftly. You can cool them down quick too. This minimizes breaking risks. It makes your job quicker and safer.

The density is high. This is critical. A thick structure quits molten steel from seeping right into the ceramic. It maintains the watercraft solid and stops leakages. You obtain a clean melt and prevent losing beneficial steel. The surface area is smooth. This makes cleansing simpler after each use.

These crucible boats are built for real-world usage. They are attempted and examined in labs and workshops. You’ll find them essential for casting, alloying, or example preparation. Their stability and long life save you cash and hassle. Pick them for requiring, high-temperature melting jobs.

(High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting)

Applications of High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

These crucible watercrafts made from 99% pure corundum alumina are crucial devices for high-temperature work. They manage severe warm exceptionally well. You can utilize them securely up to 1800 ° C (3272 ° F). This makes them best for melting steels with really high melting points. They are tough and stand up to breaking under sudden temperature adjustments. This thermal shock resistance is important for repeated home heating and cooling down cycles.

The high purity is vital. The alumina ceramic won’t react with your molten product. This keeps your gold, silver, platinum, or aluminum pure. You avoid contamination from the crucible itself. This is crucial when working with precious metals or high-purity light weight aluminum. You obtain regular, reliable results every thaw. The material likewise stands up to strike from many changes and slags made use of in metal handling.

These ceramic boats see hefty use in fashion jewelry production and rare-earth element refining. Goldsmiths and jewelers count on them to melt gold and silver for casting. They survive the extreme warm required. Labs utilize them for accurate experiments entailing high-purity steels. Aluminum foundries and recyclers utilize them for thawing aluminum scrap or alloying. The watercrafts endure the corrosive nature of liquified light weight aluminum. They are likewise common in research study settings for product synthesis and screening under extreme problems.

The smooth surface stops product sticking. This makes putting molten metal much easier and cleaning less complex after usage. The boats use outstanding toughness. They last much longer than less expensive alternatives under extreme problems. This saves cash in time. Choose the ideal shapes and size for your furnace or kiln. Handle them meticulously when hot. Constantly comply with secure handling procedures for high-temperature devices. These crucibles offer a dependable, high-performance service for requiring melting tasks.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

What material is this crucible boat?

It’s made from high-pure alumina. The purity is 99%. This means it’s mostly Al2O3. This material is safe for melting precious metals. It won’t add impurities to your gold or silver.

How hot can it get?

This crucible boat handles very high heat. Its maximum temperature is 1750°C (3182°F). This is hot enough for melting gold, silver, aluminum, copper. It won’t melt or soften at these temperatures.

How long will it last?

It lasts longer than cheaper crucibles. Its high purity and density make it strong. It resists wear from molten metal and slag. Actual life depends on your usage. Follow the handling instructions. Avoid sudden temperature changes. This helps it last many melts.

Can it crack from heat shock?

It resists thermal shock well. Its high purity helps. Preheat it slowly before use. Avoid placing a cold crucible into a hot furnace. Avoid dropping cold metal into hot molten metal inside it. Doing these things prevents most cracks.

How do I clean it?

Let it cool down completely after use. Tap it gently to remove leftover metal slag. Use a soft brush or compressed air for stuck bits. Don’t use water or harsh chemicals. They can damage the ceramic. Store it dry and handle it carefully to avoid chips.

(High Pure Refractory 99% Corundum Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Cylinder With Lid 4 Holes Fire Refractory Laboratory99.8% Ceramic Alumina Boat Crucible

Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

High density industrial 99% alumina ceramic boat crucible

AL2O3 Cordierite Ceramic Boat Crucible Alumina Ceramic Melting Crucible

99.7 Al2o3 Alumina Ceramic Crucible Boat