Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

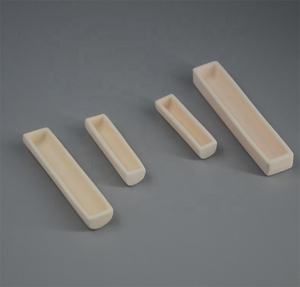

Overview of High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting)

Specifications of High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

This alumina crucible boat handles high-temperature steel melting. It’s made from costs 99% Al ₂ O five diamond. This material is very pure. High purity makes sure marginal contamination of your melts. It works for gold, silver, light weight aluminum, and similar steels.

The crucible boat supplies excellent resistance to warm. It withstands temperatures as much as 1750 ° C (3182 ° F). This makes it a leading refractory product. Thermal shock resistance is strong. Unexpected temperature adjustments trigger less cracking. The structure is thick. Density protects against molten metal penetration. Your melts keep cleaner.

Its physical homes are robust. Hardness is high. This battles wear and abrasion. Chemical security is excellent. Acids and bases create little damages. The product won’t respond with a lot of molten steels. Your metal purity continues to be high.

Criterion sizes are common. Personalized forms are feasible. Dimensions match regular furnace demands. Wall surface thickness offers excellent insulation. Thermal performance is improved. The watercraft form holds molten steel securely. Splilling threat is lower.

Use this sagger for consistent melting results. It lasts longer than more affordable choices. Efficiency is reliable batch after set. Upkeep is straightforward. Clean it after each usage. Handle it very carefully to stay clear of chips. Shop it in a dry place. This crucible boat is a practical selection for precious metal job.

(High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting)

Applications of High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

This alumina crucible boat handles extreme warm. It thaws gold, silver, light weight aluminum easily. Made from 99% pure corundum, it withstands extremely heats. This pureness implies practically no contaminations. You get cleaner melts. Your precious metals stay pure. The material is Al2O3 ceramic. This is extremely secure. It will not react with liquified metals. Your melt keeps uncontaminated. This matters for high quality results.

These ceramic components are unbelievably long lasting. They hold up against thermal shock. Abrupt temperature level adjustments won’t fracture them easily. This makes them last much longer. You save cash gradually. They beat less expensive crucibles that break fast. Their strength avoids warping or splitting under tons. You can count on them set after batch.

These sagger crucibles function well in heaters. They fit induction melting arrangements. Jewelers use them for casting. Refiners use them for detoxifying metals. Enthusiasts discover them wonderful for small projects. Labs require them for exact experiments. They are crucial for regular, high-purity melts.

The smooth surface area quits product sticking. This makes cleaning simple. You invest much less time maintaining your devices. The shape is effective. It holds steel securely. Heat transfers equally. Your steel melts consistently. This saves power and time.

Pick this crucible for reliable performance. It handles demanding melting tasks daily. Its sturdiness and purity secure your valuable metals. You obtain regular, specialist results every use.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

What exactly is this crucible made of?

It’s pure alumina ceramic. We use over 99% corundum. That’s Al2O3. This material is incredibly hard and resistant to heat. It handles extreme conditions well.

How hot can I safely use it?

These crucibles tolerate temperatures up to 1800°C (3272°F). That’s plenty hot for melting gold, silver, platinum, aluminum, and copper. Don’t exceed the limit. Doing so risks damage.

What metals work best with it?

It’s ideal for precious metals like gold and silver. It also works perfectly for aluminum and copper alloys. The pure alumina resists chemical reactions with these melts. It keeps your metal clean.

How long will one crucible last?

Lifespan depends heavily on your specific use. Factors include the exact metal melted, the peak temperature reached, and how carefully you handle it. Proper care extends its life significantly. Expect many uses under normal conditions.

Are there special handling rules?

Avoid sudden, extreme temperature changes. Heat it up slowly. Let it cool down slowly too. This prevents thermal shock cracks. Never expose a cold crucible directly to high heat. Always preheat it gradually. Handle it carefully to avoid chips or cracks. Check for damage before each use.

(High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting)

REQUEST A QUOTE

RELATED PRODUCTS

C795 C799 High Purity Refractory Corundum Al2O3 Alumina Ceramic Crucible Sagger Tray Boats

Laboratory Use Ceramic Boats 99% Alumina Ceramic Boat Corundum Ceramic Sagger

Customized Shape and Size Alumina Ceramic Crucible Al2O3 Molten Metal Ceramic Boat

High Working Temperature Rectangle Arc Boat Various Shape Supply 99.6% Alumina Ceramic Crucible Lid Available for Laboratory

95% 99% 99.7% High Thermal Alumina Corundum Ceramic Crucible Boat with Hole Block Pattern Refractory Material-MgO and SiO2