Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

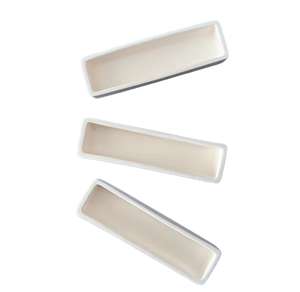

Overview of High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats

High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats)

Specifications of High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats

Right here are the specs for our high purity 99% Al2O3 alumina/zirconia ceramic tubes, crucibles, and boats. They are made from an unique mix of alumina and zirconia. This mix provides superb strength and sturdiness. They stand up to damaging far better than plain alumina porcelains. The primary material is over 99% pure alumina. This high pureness is crucial. It prevents contamination of your materials during use.

These components manage very high temperatures. They function fine approximately 1700 ° C continuously. They handle short ruptureds also hotter. Their thermal shock resistance is excellent. They handle rapid home heating and cooling down cycles well. This makes them reliable for demanding heating system job. The density is high. This provides reduced porosity. They do not soak up fluids conveniently. This enhances chemical resistance.

They stand up to strike from numerous acids and alkalis. They are extremely steady in rough chemical settings. You need this for processing aggressive products. Their electrical insulation buildings are superior. They are ideal for digital applications. The surface coating is smooth. This lessens sticking and makes cleansing simpler. They are dimensionally secure. They maintain their sizes and shape via repeated heating cycles.

These tubes, crucibles, and boats are utilized in numerous industries. Semiconductor making relies upon them. High temperature furnaces use them daily. Research laboratory analysis needs them for example prep work. Steel handling uses them for melting and casting. Any application needing pure, strong, heat-resistant porcelains benefits from them. They supply long service life and reliable efficiency.

(High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats)

Applications of High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats

These high-purity ceramic items are crucial in demanding industries. Alumina (Al2O3) at 99% pureness and zirconia (ZrO2) supply remarkable performance. Tubes, crucibles, and watercrafts made from these materials take care of severe problems accurately.

Their crucial strength is withstanding very high warmth. These ceramics conveniently endure temperature levels over 1600 ° C. This makes them ideal for heater cellular linings and heating element protection tubes. They preserve form and stability under extreme thermal stress and anxiety.

Chemical inertness is another major benefit. High-purity alumina and zirconia will not respond with many compounds. This is crucial for thawing precious metals like platinum or gold. Crucibles prevent contamination ensuring pure melts. Boats accurately bring examples through aggressive chemical vapor deposition (CVD) processes.

The semiconductor sector depends greatly on these porcelains. Their pureness stops undesirable doping of sensitive silicon wafers. Crucibles hold silicon for crystal development. Boats transfer wafers during high-temperature annealing actions. Tidiness is non-negotiable below.

Zirconia provides remarkable strength compared to alumina. It stands up to splitting under thermal shock much better. This is important where fast temperature level changes occur. Think satiating processes or thermal cycling tests. Zirconia tubes and boats master these difficult settings.

Both products withstand wear and abrasion very well. This expands the life-span of tubes made use of as thermocouple sheaths in harsh kilns. Boats sliding via furnace tracks last much longer. Lowered replacement regularity saves substantial expenses.

Electric insulation is an additional crucial home. Alumina tubes efficiently separate burner in industrial furnaces. They protect against brief circuits making certain secure operation. Their stability under electric loads is trustworthy.

These porcelains are the sensible choice for labs and production. They manage high heat, stand up to chemicals, and stay clean. Their resilience lowers long-term overhead. Efficiency matters most in essential applications.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats

What makes your alumina/zirconia tubes so pure?

We guarantee 99% purity. This means almost no impurities. Impurities cause problems. High purity ensures consistent performance. It makes the ceramics reliable for tough jobs.

How hot can these ceramic items get?

They handle very high temperatures. Alumina tubes go up to 1700°C. Zirconia ones manage about 1500°C. This suits most lab and industrial furnace work. They won’t crack or melt easily.

Can they resist strong chemicals?

Yes, absolutely. Both alumina and zirconia are inert. Acids and bases don’t attack them easily. This is crucial for chemical processing. Your samples stay safe from contamination.

What sizes do you offer?

We stock common sizes for tubes, crucibles, and boats. Need something different? Ask us. We make custom shapes and sizes. We adapt to your specific requirements.

How should I handle and clean them?

Handle them carefully. They are strong but can chip if dropped. Clean them with mild detergents or solvents. Avoid harsh abrasives. Gentle cleaning keeps them performing well longer.

(High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Ceramic Resistor-Alumina Zirconia Plate Rods Boat Wire Wound Ball Shape for Ball Mill Use Welding Service Available

Custom Alumina Ceramic Al2o3 Boats

Hot ing Corundum Alumina Ceramic High Temperature Boat Crucible for Melting Usage

Refractory High Al2o3 Cup-shaped Cylindrical Big Diameter Alumina Crucibles Large Size Crucible Ceramic Custom Gravy Boat

Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible