Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

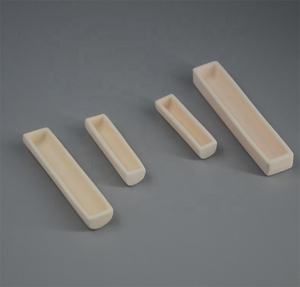

Overview of High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles

High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles)

Specifications of High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles

This combustion watercraft is made from high pureness alumina ceramic. Its Al two O ₃ web content reaches 99%. This pureness is crucial for demanding applications. The ceramic offers outstanding resistance to high temperatures. It functions reliably up to 1700 ° C (3092 ° F). This makes it excellent for sample prep work in labs. It manages intense warmth in furnaces without degrading.

The product reveals outstanding thermal shock resistance. It deals well with fast temperature adjustments. Unexpected heating or air conditioning rarely causes cracks. This toughness guarantees a lengthy service life. It conserves prices on regular replacements. The ceramic is likewise very chemically inert. It endures attack from solid acids and bases. This inertness stops example contamination. Your outcomes remain accurate.

These crucibles include a smooth, polished surface area. This coating lessens sample sticking. Cleaning up in between usages is uncomplicated. The watercraft shape is developed for reliable combustion. Examples warmth evenly within. Its measurements are specific. Common dimensions consist of 90mm length, 15mm size, and 10mm height. Other sizes are readily available. Inspect the certain product listing.

This item matches numerous logical procedures. It is ideal for ashing natural materials. Use it for loss on ignition examinations. It works well in high temperature calcination. The watercraft is compatible with muffle furnaces. It fits typical tube heaters also. Its high pureness makes certain no unwanted elements leach right into your sample. Consistency is assured batch after set. This alumina watercraft is a dependable device for exact thermal analysis. It satisfies the strict requirements of research study and quality control labs.

(High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles)

Applications of High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles

These ceramic burning watercrafts and crucibles are made from 99% pure light weight aluminum oxide. This high pureness makes them exceptionally difficult and steady under intense warm. Labs and markets use them for requiring high-temperature work. Their resistance to thermal shock implies they don’t split quickly when temperature levels alter quickly.

Burning watercrafts are long and superficial. They are perfect for holding examples throughout evaluation. Usual usages consist of determining carbon, sulfur, or hydrogen web content in products. The watercraft form enables excellent air movement over the sample. This makes certain full burning. The ceramic itself will not pollute your outcomes. It deals with acids and bases well too.

Alumina crucibles are deeper containers. They are optimal for melting, calcining, or sintering materials. You locate them in metal processing, glass production, and advanced porcelains manufacturing. They endure temperature levels much past what steel crucibles can manage. They resist assault from lots of liquified steels and slags. This maintains your thaw pure.

These products surpass cheaper choices like porcelain. They last a lot longer under rough problems. Their high pureness decreases interaction with your examples or thaws. This integrity is essential for consistent results in study and quality assurance. They are important devices where severe heat and chemical security issue the majority of.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles

High Purity 99% Al2O3 Ceramic Combustion Boat Alumina Ceramic Crucibles: Your Questions Answered

What temperature can these ceramic boats handle? These alumina ceramic boats withstand high heat. They work reliably up to 1700°C (3092°F). This makes them perfect for furnace work, ashing samples, or high-temperature analysis.

Are these boats resistant to chemicals? Yes, they resist chemicals very well. The high purity 99% Al2O3 material fights off acids and alkalis. This resistance is crucial for clean experiments. You avoid contamination from the boat itself.

Can these boats handle sudden temperature changes? Yes, they handle thermal shock well. Alumina ceramic resists cracking when heated or cooled fast. This durability is important for many lab procedures involving rapid temperature shifts.

How should I clean these ceramic boats? Cleaning is straightforward. Soak used boats in a suitable acid solution, like hydrochloric acid. Rinse them thoroughly with clean water afterwards. Dry them completely before using them again.

Can I reuse these alumina ceramic boats? Absolutely, you can reuse them many times. Their toughness and chemical resistance ensure long service life. Proper cleaning after each use is key for consistent results.

(High Purity 99% Al203 Ceramic Combustion Boat Alumina Ceramic Crucibles)

REQUEST A QUOTE

RELATED PRODUCTS

Labs Al2o3 Alumina Ceramic Combustion Boat

Lab Use Porcelain Alumina Ceramic Combustion Burning Boat 77mm 97mm

Combustion Alumina Ceramic Boat Crucible for Chemical Experiment

99% Al2O3 Alumina Combustion Boat , Rectangle Alumina Ceramic Boats Crucible

High Temperature Rectangle Alumina Ceramic Boat