Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

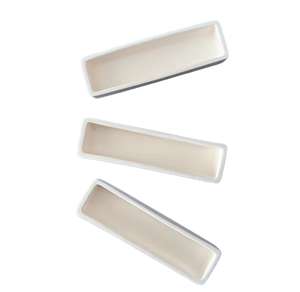

Overview of High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible

High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible)

Specifications of High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible

Here are the specifications for our High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible. This crucible handles extreme heat. It works well for melting metals, chemicals, and other high-temperature processes. The material is 99% pure aluminum oxide (Al2O3). This high purity ensures excellent chemical resistance. It resists acids and alkalis effectively.

The maximum working temperature reaches 1750°C (3182°F). Short-term use can go even higher. This crucible withstands intense heat without degrading. Thermal shock resistance is very good. It handles rapid temperature changes well. This prevents cracking during heating or cooling cycles.

Material density is high. This provides excellent mechanical strength. The crucible resists wear and abrasion over time. Surface finish is smooth. This minimizes material sticking after melting. It makes cleaning easier. Various sizes and shapes are available. Common shapes include boats, rectangles, and custom designs. Dimensions are precise. This ensures consistent performance batch after batch.

Typical wall thickness ranges from 3mm to 10mm. Thickness depends on the crucible size and application needs. Thicker walls offer more durability for heavy use. These crucibles are essential tools in labs and industry. They are used for sample preparation, ash testing, and metal casting. They perform reliably in demanding environments like furnaces and kilns.

(High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible)

Applications of High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible

Alumina ceramic melting boats and combustion crucibles handle extreme heat. They are made from Al2O3 alumina. This material is very stable. It works well past 1700°C. Many industries need this high heat capability.

These crucibles are vital in labs and factories. Scientists melt metals and chemicals in them. They are used for precious metals like gold and platinum. Jewelers and refiners rely on them daily. They also work for glass fusing and enamel applications. Their shape holds molten material safely.

Chemical resistance is a major benefit. Alumina ceramic fights off strong acids and bases. It won’t contaminate your melts. This is critical for pure results. You get accurate analysis and consistent quality. No unwanted elements sneak in.

Thermal shock resistance matters too. These crucibles handle sudden temperature changes well. You can heat them fast. You can cool them fast. They resist cracking better than many other materials. This makes them reliable through repeated cycles.

Purity is guaranteed. High-grade Al2O3 ceramic ensures this. It’s ideal for sensitive electronic materials. Semiconductor production uses them. Optical glass makers need them too. Any process needing uncontaminated melts benefits.

Durability means value. Alumina ceramic melting boats last much longer than cheaper options. They withstand rough handling. They endure constant high heat. You save money over time. You avoid frequent replacements.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible

What temperature can this crucible handle?

It withstands continuous heat up to 1750°C (3182°F). This is its maximum safe working temperature. Exceeding this temperature risks cracking or deformation. Always stay below this limit for reliable performance.

Does it resist chemical corrosion?

Yes, it resists most acids and molten salts very well. Strong alkalis like sodium hydroxide can damage it over time. It handles common laboratory fluxes. Avoid harsh chemicals for best results.

Will it crack from sudden temperature changes?

It handles thermal shock better than many ceramics. Still, avoid extreme rapid heating or cooling. Gradual temperature changes are safer. Severe shocks can still cause cracks. Follow recommended heating/cooling rates.

How long does this melting boat last?

Lifespan depends heavily on your usage. Frequent extreme heating cycles shorten its life. Gentle handling and avoiding thermal shock helps. Proper care makes it last for many uses. Rough handling or overheating breaks it faster.

How do I clean it after use?

Let it cool completely first. Remove residue with a soft brush or non-abrasive tool. Soaking in mild acid can help dissolve stubborn material. Avoid harsh mechanical scratching. Rinse it thoroughly with water afterwards.

(High Temperature Al2O3 Alumina Ceramic Melting Boat Combustion Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Alumina Combustion Boat with Lid , Rectangle Alumina Ceramic Boats Crucible

Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum

Corundum Alumina Ceramic Combustion Boat Unglazed

High Temperature 99% Al2O3 Sagger Alumina Ceramic Boat Used in Kiln

1500-1800C High Temperature Industrial Big Crucible 99 Alumina Square Ceramic Crucible Ceramic Alumina Boat Crucible