Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

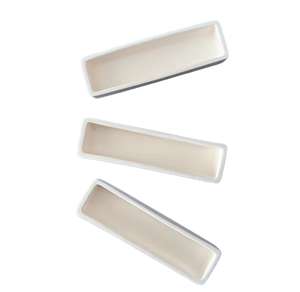

Overview of High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat)

Specifications of High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

This crucible boat is made from 99.7% pure alumina ceramic (Al2O3). It’s created for high-temperature melting experiments. The material provides extraordinary purity. This purity minimizes contamination of your samples. You get reliable outcomes.

It stands up to incredibly high temperatures. Its optimum constant usage temperature level is 1800 ° C (3272 ° F). This makes it appropriate for melting steels, glass, and various other demanding products. It takes care of sudden temperature changes well. Thermal shock resistance avoids fracturing during quick home heating or cooling down cycles.

The crucible reveals superb chemical security. It stands up to strike from several acids, alkalis, and molten materials. It won’t respond with most compounds. This chemical inertness safeguards your experiments. It makes certain the crucible product doesn’t interfere.

Its mechanical strength is high. The crucible stands up to physical wear and abrasion. It preserves its shape under lots at high warm. This longevity indicates it lasts longer. You conserve money on replacements.

The surface area is extremely smooth. This level of smoothness stops product sticking. Cleansing is much easier after use. The crucible includes reduced porosity. This decreases absorption of melts. It keeps your materials pure.

This alumina ceramic crucible watercraft helps laboratory research study. It benefits commercial procedures like steel evaluation. It works for product synthesis. It works for quality control testing. It’s a trustworthy device for accurate high-heat applications. Common usages involve platinum group metals, uncommon earth elements, glass frits, and ceramic powders.

(High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat)

Applications of High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

This alumina ceramic crucible boat manages severe warmth. Lab workers trust it for laborious. Its pure 99.7% Al2O3 makeup eliminate deterioration. It stands strong against hostile chemicals. This crucible thaws metals like gold or silver quickly. It handles copper alloys without failing. Scientists use it for preparing specific steel samples. It functions well for examining ore make-ups. Jewelers rely on it to cast small valuable things. Its high pureness keeps samples uncontaminated. This matters for exact examination results.

The crucible holds up against temperatures over 1700 ° C. This makes it excellent for furnace job. It deals with unexpected temperature changes well. This thermal shock resistance prevents splitting. Employees heat it quick. They cool it quickly. The crucible remains intact. Its smooth surface stops materials sticking. Clean-up remains basic after melting. Workers save time.

Its form fits many heating system types. The boat style holds powders securely. It includes liquified liquids safely. This crucible lasts a long time. It stands up to wear from duplicated home heating cycles. Labs get value from its longevity. Factories utilize it for alloy growth. Universities require it for materials scientific research experiments. It serves glass research as well. This crucible deals with numerous fluxes. Assembly line use it for quality checks. It executes dependably batch after set. Employees appreciate its constant efficiency.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

What’s the max temperature this crucible handles?

This crucible handles extreme heat. It works safely up to 1700°C (3092°F) in air. It handles brief spikes near 1800°C. Don’t use it beyond this. Doing so risks damage.

How do I clean it after melting experiments?

Cleaning is straightforward. Let the crucible cool completely first. Use warm water and a soft brush for basic residue. For stubborn stuff, soak in dilute acid like hydrochloric acid. Rinse it very well with water afterward. Never use abrasive tools.

What metals or chemicals work with it?

This alumina crucible resists most stuff. It works great with common metals like gold, silver, copper. It also handles many oxides and salts. Avoid strong alkalis like sodium hydroxide. Avoid hydrofluoric acid too. These chemicals attack alumina.

Why pick alumina over graphite or quartz?

Alumina offers key benefits. It handles higher heat than quartz. It lasts longer than graphite against oxidation and wear. It resists chemical attack better than both in many cases. It gives pure results with less contamination risk.

Any special handling needed?

Handle it carefully. Alumina ceramic is strong but brittle. Avoid drops or hard knocks. Protect it from sudden temperature changes. Heat it up slowly. Cool it down slowly. This prevents thermal shock cracks. Store it somewhere safe.

(High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible

Hot ing Corundum Alumina Ceramic High Temperature Boat Crucible for Melting Usage

99% AI2O3 Alumina Ceramic Square Combustion Boat Laboratory Specific Corundum Sintering Boat

95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

Laboratory Use Ceramic Boats 99% Alumina Ceramic Boat Corundum Ceramic Sagger