Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

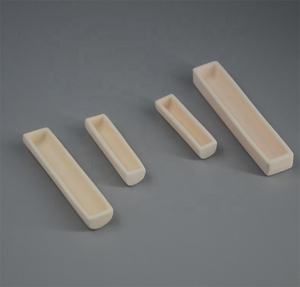

Overview of High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace

High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace)

Specifications of High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace

This rectangle-shaped ceramic watercraft is made from high-purity alumina. It deals with severe warmth well. You can utilize it continually as much as 1650 ° C. Short ruptureds to 1750 ° C are feasible. The product is thick and strong. It resists chemical attack. Acids and bases won’t damage it quickly. A lot of molten metals are secure as well. It copes with sudden temperature level adjustments. Quick home heating or cooling down reasons less splitting. Thermal shock resistance is excellent. This makes it dependable for many furnace cycles.

The watercraft form is long and rectangular. It holds examples or tiny parts successfully. You can put several products inside. Uniform heating occurs across the tons. The style permits simple loading and discharging. Tongs work well with it. Crucibles fit nicely inside the watercraft in some cases. This depends upon their size. The level base provides security. It won’t topple easily. The wall surfaces are thick sufficient for strength. They remain inflexible even at optimal temperature levels.

Surface coating is smooth. This prevents material sticking. Cleansing is easier after use. Contamination in between batches is reduced. The alumina is very pure. Micronutrient are minimal. This stays clear of unwanted responses with delicate materials. It appropriates for semiconductor handling. Ceramic sintering utilizes it often. Powder metallurgy gain from it. General high-temperature experiments need it. The watercraft is reusable. It lasts sometimes if handled correctly. Stay clear of sharp impacts though. Alumina can chip if gone down. Manage it thoroughly. Store it in a clean, dry location. Moisture absorption is low. Long-term storage space is fine. Check for cracks prior to each usage. Safety and security initially. Replace it if damaged.

(High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace)

Applications of High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace

This heat rectangle-shaped ceramic watercraft alumina crucible serves numerous heater tasks. It takes care of severe warm well. Alumina ceramic withstands temperature levels over 1700 ° C. This makes it best for requiring heater work. The rectangle-shaped boat form is very useful. It holds several samples or parts effectively. You refine batches properly. Workers use it for warm therapy. Annealing metals occurs inside it. So does toughening up glass samples. Sintering powders is one more key work. The watercraft holds powder compacts firmly throughout high heat firing. It maintains forms secure. Crystal development procedures rely on these boats. They sustain substrates or resource products uniformly. This makes certain also crystal formation. Chemical vapor deposition (CVD) utilizes them as well. The watercraft brings wafers or parts via the response zone. Its purity matters. Alumina will not infect sensitive materials. It withstands chemical assault from lots of fluxes or gases. Thermal shock resistance is very important. The crucible endures fast temperature level adjustments without cracking. This sturdiness saves time and money. Labs need this crucible for study. Production lines utilize it for production. It works in tube heaters and box heaters. The style enables easy loading and discharging. Dealing with examples comes to be simpler. Regular efficiency is ensured. This tool is necessary for high temperature material job.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace

What is this ceramic boat made from?

It uses high purity alumina ceramic. This material handles extreme heat very well. It resists chemicals strongly too.

How hot can it get?

These boats safely reach 1750°C (3182°F). They handle short bursts even higher. Never exceed 1750°C for long periods.

Will it crack from sudden temperature changes?

It has good thermal shock resistance. It manages rapid heating or cooling cycles. Avoid extremely fast changes still. They could cause stress cracks.

Can I use it with other materials?

Check the material’s expansion rate first. Alumina expands differently than silicon or graphite. A big mismatch causes cracks. Match materials carefully.

How do I clean it after use?

Let it cool completely first. Soak it in warm, diluted acid like HCl or HNO₃. Avoid rough scrubbing. It might scratch the surface. Rinse it very well with pure water. Dry it thoroughly.

Are the dimensions exact?

We make them to tight tolerances. Size variations stay under 1%. This ensures consistent sample placement. Contact us for specific size needs.

(High Temperature Rectangular Ceramic Boat Alumina Crucible for Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Alumina Combustion Boat with Lid , Rectangle Alumina Ceramic Boats Crucible

High Working Temperature Rectangle Arc Boat Various Shape Supply 99.6% Alumina Ceramic Crucible Lid Available for Laboratory

Alumina Ceramic Crucible Boat

High Temperature Trapezoidal Shape Ceramic Alumina Boat Crucible for Melting Furnace

99% High Alumina Ceramic Crucible Cylinder Al2O3 Alumina Combustion Boat With Lid , Rectangle Alumina Ceramic Boats Crucible