Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

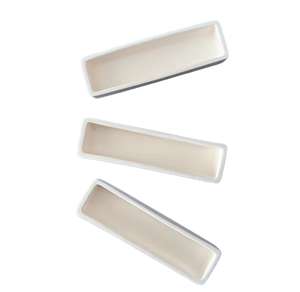

Overview of High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat

High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat)

Specifications of High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat

This alumina burning tray takes care of extreme heat. It’s made from high-purity Al2O3 ceramic. This material withstands temperatures up to 1750 ° C. It’s ideal for demanding furnace applications. The tray stands up to thermal shock extremely well. Unexpected temperature level modifications will not split it quickly. High purity suggests over 99% alumina content. This pureness gives exceptional chemical security. The tray will not respond with the majority of products refined inside it. It remains inert also under extreme conditions. This prevents contamination of your samples or materials. The ceramic is thick and non-porous. This structure stops gases or liquids permeating via. It gives a reputable, clean surface. The tray uses terrific mechanical toughness. It holds its shape under hefty loads at high heat. It won’t sag or deform quickly. This sturdiness ensures lengthy life span. We make these trays in several common dimensions. Usual dimensions are offered for immediate shipment. Need a various size or shape? We customize trays to your specific requirements. Supply your details illustrations or dimensions. We produce custom-made Al2O3 heater boats quickly. Custom trays satisfy the same high-performance standards. They deal with the exact same extreme temperature levels. They use the exact same chemical resistance. They deliver the same resilience. Our customization covers numerous measurements. We alter length, width, and deepness. We adjust wall surface thicknesses. We develop one-of-a-kind shapes for specialized procedures. We focus on your specific heating system requirements.

(High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat)

Applications of High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat

Alumina burning trays fix high heat troubles. These customized ceramic watercrafts take care of severe temperature levels conveniently. Made from almost pure Al2O3 alumina, they stand up to thermal shock. This suggests they won’t break or warp under unexpected temperature level modifications. They work reliably in heating systems getting to 1800 ° C or more. This stability is crucial for demanding procedures.

You require constant performance in extreme atmospheres. These trays deliver. Their high purity makes sure marginal contamination. This matters for sensitive products like semiconductors or catalysts. The trays won’t respond with your samples. They keep your procedure clean.

Customization is vital. Criterion sizes usually do not fit. We make trays to your precise specifications. Required a certain length, size, or depth? We construct it. Unusual forms for special tools? We produce those also. Our custom-made Al2O3 watercrafts fit your heating system perfectly. This enhances efficiency and security.

These trays offer numerous important applications. They are vital for sintering sophisticated ceramics. They hold parts firmly throughout high-temperature shooting. They are vital in powder metallurgy processes. They move steel powders via sintering heaters. They are essential for stimulant r & d. They support stimulant examples during activity testing. They play a key role in warmth therapy procedures. They lug parts for annealing or brazing. They are fundamental in materials testing labs. They hold samples for creep or oxidation studies. They sustain MIM (Metal Shot Molding) debinding and sintering. They guarantee parts sinter properly without distortion.

The thick alumina framework gives excellent wear resistance. It endures duplicated thermal biking. This gives a lengthy service life. It minimizes substitute expenses and downtime. The material uses good chemical inertness. It stands up to assault from many molten steels and salts. This flexibility is a major advantage. Handling is simple. The trays maintain dimensional security cycle after cycle. This reliability is essential for industrial production. Proper treatment makes certain maximum performance. Stay clear of abrupt temperature shocks during loading and unloading. Comply with recommended heating & cooling rates. This protects the tray honesty.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat

Here are the top 5 questions people ask about our custom high-temperature alumina combustion trays:

What temperature can these Al2O3 trays handle? Our trays resist extreme heat. They work reliably up to 1800 degrees Celsius. This makes them perfect for demanding furnace work. They won’t melt or weaken easily.

Can you make trays in specific sizes or shapes? Yes. We specialize in custom orders. Tell us the exact dimensions you need. We can make different lengths, widths, and heights. We also create unique shapes for special setups. Just provide your drawings or details.

Why pick alumina over other ceramics? Alumina ceramic offers key advantages. It handles very high heat well. It also resists chemical corrosion. This means harsh materials won’t damage it easily. Alumina stays strong under tough conditions. It lasts longer than many alternatives.

How long do these ceramic boats last? Lifespan depends heavily on use. Extreme temperatures and thermal cycling cause wear. Using trays within their rated limits helps. Proper handling prevents cracks. Typically, they last for many heating cycles. They are durable for demanding lab or industrial work.

Are there special handling instructions? Yes. Alumina ceramic is strong but brittle. Avoid impacts or dropping the trays. Sudden temperature changes can cause stress cracks. Heat and cool them gradually. Store them safely to prevent chipping. Clean them carefully to avoid contamination. This keeps your results accurate.

(High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature of The Sagger Box Rectangle Alumina Crucible Ceramic Refractory Crucible Boat

High Purity 99% Al203 Alumina/zirconia Ceramic Tubes/crucibles/ Boats

High-Temperature Al2o3 Tray Clay Hardness Good Alumina Ceramic Combustion Boat Crucible

95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

High Purity Good Strength Refractory Alumina Ceramic Crucible Boat Shape Alumina Crucible