Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

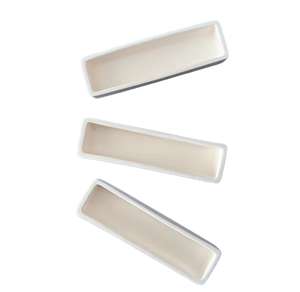

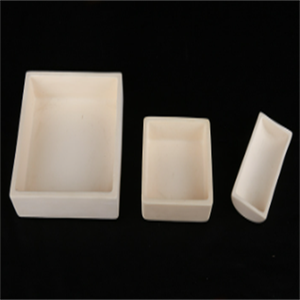

Overview of High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat)

Specifications of High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

This alumina porcelain cupel watercraft deals with severe warm effectively. It’s made for appraising and thawing precious metals. The material is pure. It contains 99.7% alumina ceramic. This purity makes it extremely strong against heat and chemicals.

It stands up to temperature levels up to 1750 ° C (3182 ° F). This high warmth ability is vital. Several commercial procedures need it. The cupel watercraft won’t crack or warp easily. Thermal shock resistance is excellent. You can heat it fast. You can cool it fast. It remains stable.

Chemical stability is another major benefit. It won’t respond with a lot of molten steels or changes. This is crucial for exact analysis. You obtain dependable results each time. The surface area is extremely smooth. This stops material sticking. Cleaning up is less complicated too.

Density is high, over 3.8 g/cm SIX. High density means much less porosity. The boat soaks up virtually nothing. Contamination dangers are marginal. Your examples stay pure. Mechanical strength goes over. The boat takes care of physical stress and anxiety well. It lasts long even with heavy usage.

Criterion sizes are offered. Usual dimensions fit many lab heating systems. Personalized shapes are feasible. We make them to your precise requirements. Normal usages include silver and gold assaying. Platinum team steel melting uses them. Heat testing utilizes them. They operate in air or inert gas.

The alumina porcelain framework ensures durability. It outperforms typical materials. It offers a trustworthy option for demanding applications.

(High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat)

Applications of High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

Alumina porcelain ceramic cupel boats are unique devices for very warm lab job. They handle severe temperatures easily. These boats rise to 1700 ° C without breaking. This makes them best for fire assaying. Fire appraising checks rare-earth elements like gold and silver. The cupel watercraft holds the sample throughout this intense home heating. Normal products thaw or react terribly at these warms. Alumina porcelain stays solid. It doesn’t react with the hot steel or fluxes. This chemical security is crucial. You get precise outcomes because the boat doesn’t interfere. These watercrafts are also extremely challenging. They withstand thermal shock well. Abrupt temperature level modifications normally fracture ceramics. Alumina porcelain handles them much better. This strength implies the watercrafts last long. Labs save money due to the fact that they don’t change them typically. The smooth surface is one more plus. Molten metal slides off conveniently after the examination. Cleanup is easy. You recycle the watercraft often times. These buildings make cupel boats vital beyond appraising. They are made use of in sintering processes. Sintering bonds powder materials under warmth. They work in calcination as well. Calcination drives off unstable parts from minerals. They are good for warm dealing with small products. Researchers count on them for high-temperature experiments. The watercrafts offer a dependable, inert container. They guarantee consistent performance pursue run. Labs handling severe warmth need this reliability. Alumina porcelain supplies it.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

Here are 5 common questions about High Temperature Resistant Alumina Porcelain Ceramic Cupel Boats:

What is the highest temperature these cupel boats handle?

These alumina porcelain ceramic cupel boats handle continuous use up to 1750°C (3182°F). They are made for extreme heat. They resist melting or softening at these temperatures.

Is the ceramic material safe for melting precious metals?

Yes, the ceramic material is chemically inert. It does not react with molten metals like gold or silver. Your samples stay pure. The cupel boat won’t contaminate them.

Can the cupel boat handle sudden temperature changes?

The cupel boat resists thermal shock well. Avoid very rapid heating or cooling. Always heat it gradually. Cooling it slowly is best. This prevents cracks.

Can I reuse a cupel boat?

Reuse is possible. Inspect the cupel boat carefully after each use. Look for cracks, chips, or deep contamination. Discard it if you see damage. A damaged boat might fail next time. It could ruin your sample.

How do I clean a used cupel boat?

Cleaning depends on the residue. Remove loose material first. Light residue may come off with dilute acid. Be careful. Strong chemicals might damage the ceramic. Abrasive cleaning can scratch the surface. Avoid scratches. They weaken the boat. Sometimes cleaning isn’t possible. Replace the boat if heavily contaminated.

(High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat)

REQUEST A QUOTE

RELATED PRODUCTS

High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

Alumina Sagger Box Alumina Ceramic Boat

Customizable 99% Alumina Ceramic Parts Al2o3 Insulator Boat for Industrial

Customized Alumina Irregular Analysis Crucible Insulator Al2O3 Ceramic Boat

99% Corundum Ceramic Crucible Evaporation Alumina Ceramic Boat for Laboratory