Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

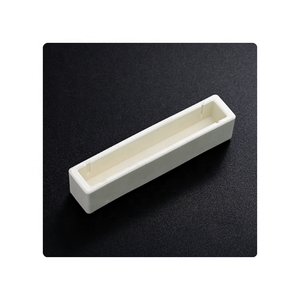

Overview of Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum

Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum)

Specifications of Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum

This fused alumina ceramic boat crucible handles extreme heat. It’s made from premium corundum material. This material is very dense and pure. It gives the crucible outstanding strength. The crucible works reliably above 1700°C. It withstands repeated heating and cooling cycles. Sudden temperature changes won’t crack it easily. This thermal shock resistance is important. Users heat or cool samples quickly sometimes. The crucible stays strong.

The material resists chemicals very well. Acids and alkalis don’t attack it easily. Molten metals and slags also won’t damage it. This chemical inertness protects your samples. It prevents contamination. Your materials stay pure during processing. The crucible itself lasts longer. It doesn’t degrade fast.

The design includes integrated handles. These handles are part of the crucible body. They are not glued or attached later. This makes them very strong and secure. You can move the crucible safely when it’s hot. Use proper tongs with the handles. The handles prevent accidents. They give you better control. Handling hot materials is less risky.

This crucible comes in standard sizes. Common sizes are available. It fits most standard tube furnaces and kilns. The shape is a shallow boat. This shape is good for spreading materials out. Samples heat evenly. It works for calcination, sintering, and heat treatment. It works for annealing processes too. Labs and industrial settings use it. It handles powders, small parts, or samples needing high purity. Expect consistent performance. The crucible maintains its shape over time. It offers good value because it lasts.

(Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum)

Applications of Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum

This fused alumina ceramic boat crucible handles extreme heat easily. Its pure corundum construction makes it incredibly tough. It withstands temperatures far beyond what metals can handle. This is vital for demanding industrial processes.

You need it for melting metals like gold, silver, or platinum. It works perfectly for processing specialty alloys too. High-temperature material testing relies on its stability. Ceramic sintering requires consistent heat; this crucible delivers. It manages glass frit production without degrading.

The key is its pure alumina content. This gives it exceptional thermal shock resistance. Sudden temperature changes won’t crack it. Its high chemical purity prevents contamination. Your melted materials stay clean. The dense structure resists erosion from molten substances. It lasts much longer than cheaper alternatives.

The integrated handle is crucial. It provides a safe grip even when the crucible is glowing hot. You avoid direct contact with dangerous heat. Moving it in and out of furnaces becomes safer and simpler. Handling hot samples is less risky. This design protects workers and improves workflow efficiency.

Its shape is ideal for laboratory and small foundry use. The boat design holds materials securely. It allows for good heat distribution. You get reliable results batch after batch. This crucible is built for heavy, repeated use. It saves money by reducing replacements.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum

Here are the key questions about our Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle:

What material is this crucible boat?

It’s made of corundum. That’s pure, high-grade aluminum oxide. This material is incredibly tough and resistant to heat. It handles extreme temperatures well.

How hot can this crucible boat get?

This boat crucible handles over 1700°C easily. It’s built for very high heat. You can use it in demanding furnace applications without worry. It won’t crack or degrade under normal high-temperature use.

Why does it have a handle?

The handle is for safety and easy moving. High-temperature work is dangerous. The handle lets you move the hot crucible securely. You use tongs on the handle. This keeps your hands far from the heat. It also gives better control when placing the boat in the furnace or taking it out.

How do I clean this crucible after use?

Cleaning is straightforward. Let the crucible cool down completely first. Then, soak it in a mild acid solution. This removes most residues. Sometimes, you might need light scrubbing. Avoid harsh impacts. This material is hard but can chip if hit forcefully.

What jobs is this crucible boat good for?

It’s perfect for high-heat labs and industry. Use it for sintering samples. Use it for calcining powders. Use it for heat-treating small parts. It works well in air or controlled atmospheres. Common places using it are research labs, universities, and materials testing facilities. It reliably holds powders or small solid pieces during intense heating.

(Hot ing Fused Alumina Ceramic High-temperature Boat Crucible with Handle Made of Corundum)

REQUEST A QUOTE

RELATED PRODUCTS

High density industrial 99% alumina ceramic boat crucible

99% Alumina Ceramic Boat Crucible Rectangle Corundum for Sintering Furnace in 15ml 25ml 50ml 100ml Sizes

Aluminum Oxide Gold Melting Al2O3 Tray Alumina Ceramic Boat Crucible

Al2o3 Alumina Boat with Holes 44*11*8mm, Al2O3 Ceramic Combustion Boat

High-Temperature Resistant Corundum Crucible Square Laboratory Ceramic Boat Alumina Crucible Square Laboratory Tube Furnace