Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

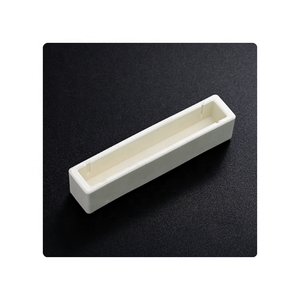

Overview of Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts)

Specifications of Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

These large rectangle-shaped burning boats are made from 99% alumina ceramic. This product is extremely solid and durable. It takes care of really high temperatures well. You can utilize these boats reliably up to 1650 ° C. They also stand up to thermal shock successfully. Sudden temperature changes won’t conveniently split them. This makes them perfect for demanding heater job.

The ceramic offers excellent chemical resistance. Harsh acids and bases won’t harm it easily. Solid alkalis and molten salts likewise create minimal strike. This stability guarantees your examples remain unpolluted. You get precise outcomes each time. The smooth surface area finish helps below also. It prevents sample sticking and streamlines cleansing after use.

We focus on customized cutting. Your certain size requirements are not a problem. Inform us the specific size, size, and height you require. We make the boats specifically to those dimensions. Uniformity is assured throughout every boat we make. Tight tolerances are conventional. This ensures reputable efficiency in your instruments.

These watercrafts are essential tools for industrial analysis. Laboratories utilize them daily for sample preparation. Common applications include ash testing and loss on ignition researches. They are vital in furnace-based evaluation treatments. The high pureness alumina ensures no unwanted components hinder your tests. Anticipate regular, repeatable efficiency set after set. Industries like concrete, metals, and chemicals rely on them. They are additionally vital in research institutions.

(Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts)

Applications of Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

Large rectangular 99% alumina ceramic combustion watercrafts are necessary devices in several commercial labs. These ceramic components are very strong. They deal with extreme heat well, over 1700 ° C. They withstand chemical assaults also. This makes them excellent for high-temperature processes. Labs use them frequently for sample evaluation.

One significant use is testing materials. The boats hold samples during combustion. They go into heaters or stoves. They measure points like ash material. They learn just how much power a product holds. They are essential for coal, coke, and gas analysis. The ceramic remains stable. It doesn’t hinder the results.

Steel analysis additionally relies on these boats. They hold metal powders or chips. The samples get heated up to really heats. The ceramic withstands molten steels and hostile fluxes. The watercraft form is important. It has the example securely. It stops material loss throughout heating.

Chemical laboratories need them for stimulant studies. Scientist examination just how drivers act under heat. The alumina ceramic does not respond. It offers a tidy, inert surface. This is critical for accurate data. Taste prep work is another essential area. The watercrafts are used to dry, ash, or calcine examples. They are reliable for repeated home heating cycles.

Personalized cutting is a large benefit. Criterion sizes don’t always fit. Heating system measurements vary. Sample dimensions differ also. Producers reduced these alumina watercrafts to exact specifications. They match one-of-a-kind furnace setups. They fit uncommon example holders. This guarantees a tight, secure fit whenever. The high pureness issues. 99% alumina minimizes contamination risks. Traces do not leach right into examples. This ensures purity in delicate analyses.

The thermal shock resistance is superb. The boats manage abrupt temperature modifications. Moving them from a warm heating system to a cooler area is safe. They do not fracture quickly. This durability conserves money. They last much longer than more affordable products. They are a trustworthy workhorse. Industries depend on them for regular, repeatable outcomes.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts

Here are 5 FAQs about Large Rectangular 99% Alumina Ceramic Combustion Boats:

What material is this combustion boat?

This boat uses 99% alumina ceramic. Alumina ceramic is very hard. It resists chemicals well. It handles extreme heat. This makes it perfect for labs and industry.

How hot can it get?

This alumina ceramic withstands very high temperatures. Its maximum continuous use temperature is 1800°C (3272°F). It handles sudden temperature changes well. This is essential for combustion analysis.

Can I get a custom size?

Yes. We specialize in custom cutting. Tell us the exact length, width, and depth you need. We cut the boat precisely to your specifications. Standard sizes are also available.

Is the boat fragile?

Alumina ceramic is strong. It is also brittle. Handle it carefully. Avoid impacts or drops. Protect the edges. Proper handling prevents chips or cracks.

Where is this boat used?

These boats are vital for high-heat industrial processes. Common uses include ash testing in coal analysis. They are used in thermal gravimetric analysis (TGA). They work in furnace applications. They are used for sample combustion. They are essential for precise material analysis.

(Large Rectangular 99% Alumina Ceramic Combustion Boat Custom Cutting Industrial Analysis Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Rectangular 95% 99% Al2o3 Alumina Oxide Ceramic Crucible Boats for Lab Melting

Lab Combustion Boat Alumina Ceramic Boat

High temperature resistance Alumina Combustion Tray customize Al2o3 Furnace ceramic Boat

High Temperature 99% Al2O3 Purity square Shape Alumina Ceramic Boat Crucible

99% Alumina Boat Shape Ceramic Crucible with Hole or Not High Temperature Alumina Crucible