Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

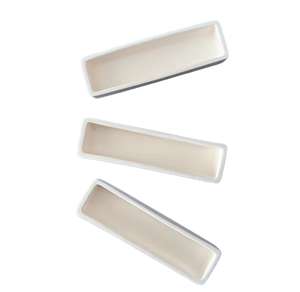

Overview of Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible

Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible)

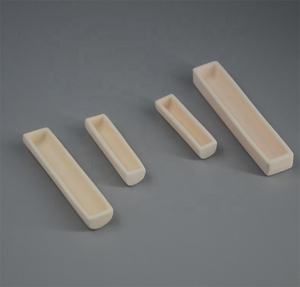

Specifications of Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible

This rectangle-shaped alumina ceramic boat actions 100mm long, 30mm large, and 20mm high. It is made from high-purity alumina ceramic. The product structure mores than 99% alumina. This makes certain excellent performance sought after high-temperature setups. The watercraft stands up to temperature levels approximately 1700 levels Celsius. It deals with fast heating and cooling down cycles well. Thermal shock resistance protects against splitting under stress. The surface area is very smooth. This protects against example contamination. It additionally makes cleaning very easy after usage. The watercraft resists strike from several acids and antacids. Chemical stability is vital for lab job. Its form is optimal for tube heating systems. It moves easily right into standard quartz or ceramic tubes. Fits tubes with 1-inch or 2-inch diameters. Utilize it to hold examples during sintering, annealing, or calcining processes. It helps powders, little parts, or wafers. The boat offers a steady, inert platform inside the heater warm zone. It is a trustworthy choice to alumina crucibles for sure shapes. Loading samples is uncomplicated. Dumping refined product is basic. The tough layout resists bending or splitting. This boat offers long life span. Recycle it many times. It conserves cash compared to non reusable alternatives. Constant efficiency set after batch is guaranteed. High pureness suggests very little outgassing. Sample integrity remains protected. The measurements supply great capacity within a portable type. This watercraft is crucial for exact high-temperature product processing.

(Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible)

Applications of Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible

This alumina ceramic watercraft steps 100x30x20mm. It’s made from high pureness alumina. This product deals with severe warmth well. It functions accurately in tube heaters approximately 1700 ° C. The rectangular form is stable. It holds examples securely during heat procedures. These include sintering, annealing, calcination, and warmth therapy. Its level base avoids tipping inside the furnace tube. Examples remain in setting during heating. The boat is chemically inert. It resists reactions with the majority of materials processed inside. This stops sample contamination. The smooth surface area makes cleansing easy after use. This watercraft is recyclable many times. It supplies excellent thermal shock resistance. This suggests it makes it through quick temperature level changes without splitting.

The same boat features as a little alumina crucible. Its dimension matches tiny batch responses. It holds powders or fluids needing high warm. The product stands up to destructive substances. It executes well in melting or fusing applications. The thick walls give resilience. They resist mechanical wear and thermal stress. The boat form allows very easy managing with tongs. Its corners stop spills. This style supports reliable material transfer in and out of heating systems. Alumina’s low thermal conductivity aids. It safeguards furnace components from straight warm direct exposure. This expands devices life.

The high pureness alumina makes certain marginal impurities. This is vital for sensitive processes. It avoids introducing unwanted elements. The watercraft is dimensionally stable. It keeps its form under extended warm. This assures consistent results run after run. Its resistance to oxidation is exceptional. This makes it suitable for various ambiences. Air, inert gases, or decreasing gases are all possible. The material is non-porous. This protects against sample absorption. It maintains the procedure environment clean. This alumina boat is a versatile device. It offers trustworthy performance in demanding laboratory and industrial settings.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible

Rectangle Alumina Ceramic Boat 100x30x20mm for Tube Furnace / Alumina Crucible – FAQs

What is this alumina ceramic boat used for?

This boat holds small samples during high-temperature processes. You use it inside tube furnaces or as a crucible boat. It’s good for sintering, calcining, annealing, or other heat treatments. Its shape keeps samples contained safely.

What temperature can it handle?

This boat withstands very high temperatures. Its maximum continuous use temperature is around 1650°C (3002°F). It handles short bursts even hotter. It won’t melt or degrade under normal furnace conditions.

How do I clean it after use?

Cleaning is usually simple. Let the boat cool completely first. Often, brushing off loose residue works. For tougher deposits, soak it in a mild acid solution like diluted hydrochloric acid. Rinse it thoroughly with water afterwards. Avoid harsh mechanical scrubbing; it can scratch the surface.

Is this ceramic boat fragile?

Yes, alumina ceramic is hard but brittle. It can chip or crack if dropped or knocked hard. Handle it carefully. Avoid sudden temperature changes. Don’t heat it up too fast. Don’t cool it down too fast. Thermal shock can cause cracks. Support it evenly during use.

Why choose alumina ceramic over other materials?

Alumina ceramic has key advantages. It resists extreme heat very well. It doesn’t react with most chemicals. It won’t contaminate your samples. It provides excellent electrical insulation. Metal boats might melt or react. Other ceramics might not be as pure or temperature resistant. Alumina offers reliable performance for demanding lab work.

(Rectangle Alumina Ceramic Boat 1003020mm for Tube Furnace / Alumina Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

High Temperature Boat-shaped Lab Use High Al2o3 Alumina Ceramic Combustion Boat

High Pure Refractory 99% Corundum Sagger Alumina Crucible Boat Al2O3 Ceramic Parts for Gold Silver Aluminum Melting

100*40*20mm Alumina Ceramic Boat Crucible with Lid , Alumina Boat

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis