Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

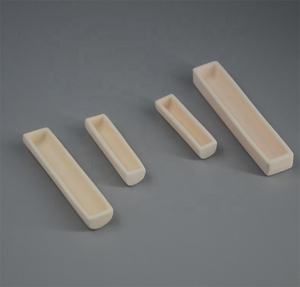

Overview of Refractory Laboratory Alumina Ceramic Boat

Refractory Laboratory Alumina Ceramic Boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Refractory Laboratory Alumina Ceramic Boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Refractory Laboratory Alumina Ceramic Boat)

Specifications of Refractory Laboratory Alumina Ceramic Boat

Right here’s the item summary for your refractory lab alumina ceramic boat. It fulfills all your requirements.

This alumina ceramic watercraft handles heats in laboratories. It’s made from pure aluminum oxide product. The pureness level is high. This ensures solid chemical resistance. Acids and bases will not damage it conveniently. The watercraft is very dense. This density gives it outstanding mechanical toughness. It won’t crack easily under tons. The optimum functioning temperature level is really high. It stands up to duplicated heating and cooling down cycles well. Unexpected temperature changes don’t damage it. Various standard dimensions are available. Usual dimensions fit many tube furnaces and kilns. The size, width, and deepness differ by model. Examine the certain measurements for your needs. The smooth surface area finish is important. It stops example contamination. Samples will not stick to the boat. A glazed surface choice exists. This polish makes cleaning less complex. It supplies an additional barrier against chemicals. These watercrafts benefit several materials. They are excellent for sintering powders. They help calcining compounds. They are good for annealing small parts. The product remains secure under warmth. It will not respond with most compounds. It won’t release impurities. Constant efficiency is ensured batch after set. Custom-made shapes and sizes are possible. Inquire about unique orders.

(Refractory Laboratory Alumina Ceramic Boat)

Applications of Refractory Laboratory Alumina Ceramic Boat

These ceramic watercrafts are vital lab devices. They handle severe heat. Labs utilize them for high-temperature work. They securely contain products during home heating procedures. Heating systems require them. Kilns need them. These boats hold samples safely. They protect against contamination. This is essential for pure outcomes. Products like powders or small components go inside. Then warm therapy happens. This changes product homes. It prepares samples for evaluation. Sintering is an usual usage. This procedure bonds bits together. It makes products more powerful. Ceramic boats endure the intense warm. They do not melt or warp. They also move samples conveniently. Workers transfer warm samples safely. The boats go from heater to cooling down location. This protects employees. It shields the samples also. Examining products is an additional essential task. Boats hold examples during thermal analysis. They see just how products react to heat. They see weight modifications or growth. Chemical resistance issues. These watercrafts battle acids and alkalis. They manage corrosive ambiences. This is essential for chemical processing tests. Their stamina prevents breaking. Thermal shock resistance is excellent. Unexpected temperature modifications will not damage them. This saves money. Labs do not replace them commonly. They are steady and inert. They do not respond with many samples. This makes certain exact examination outcomes. Cleaning up is simple. Employees recycle them many times. They are a trustworthy lab workhorse.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Laboratory Alumina Ceramic Boat

Refractory Laboratory Alumina Ceramic Boat: Key Questions Answered

What is this ceramic boat made from?

It’s made from high-purity alumina ceramic. This material is aluminum oxide. Alumina offers excellent resistance to heat and chemicals. Its purity matters. Boats are often 99% alumina or higher.

How hot can it safely go?

These boats handle very high temperatures. They work reliably up to 1700°C (3092°F). Some specialized grades withstand even higher heat. Always check the specific product rating before use.

What chemicals won’t harm it?

Alumina resists many harsh chemicals. It handles strong acids like sulfuric acid well. It handles strong bases like sodium hydroxide too. It resists many molten salts and metals. Avoid hydrofluoric acid and strong phosphoric acid. They can damage the ceramic.

How should I clean it after use?

Cleaning is usually straightforward. Use hot water first. Use a mild detergent if needed. Avoid harsh abrasives. Avoid ultrasonic cleaners. They can cause tiny cracks. For stubborn residues, soak in a suitable acid or base solution. Rinse thoroughly with deionized water afterward. Dry it completely before reuse.

Where is this boat typically used?

It’s essential for high-temperature lab work. Use it for sintering materials. Use it for calcining powders. Use it for annealing samples. Use it for firing ceramics. Use it for holding samples in furnaces. It works well in air or inert atmospheres. It’s common in materials science, chemistry, and research labs.

(Refractory Laboratory Alumina Ceramic Boat)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Rectangular 95% 99% Al2o3 Alumina Oxide Ceramic Crucible Boats for Lab Melting

High Purity Alumina Square Ceramic Boat Crucibles for Furnace at Working Temperature 1000C

High Temperature Boat-shaped Lab Use High Al2o3 Alumina Ceramic Combustion Boat

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

Lab Use Porcelain Alumina Ceramic Combustion Burning Boat 77mm 97mm