Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

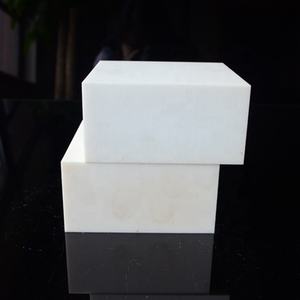

Overview of 99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile

99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of 99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile)

Specification of 99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile

These alumina ceramic bricks and plates deliver leading efficiency in difficult setups. They can be found in 2 main purity grades: 99% Al2O3 and 95% Al2O3. The greater purity indicates better resistance. The 99% quality handles extreme warmth much better. It withstands temperature levels soaring past 1700 ° C. Its solidity is outstanding. Use and corrosion hardly touch it. This makes it excellent for extreme wear spots. The 95% grade offers a strong balance. It offers outstanding warm resistance too. It costs less than the 99% variation. This is a clever choice for many demanding work.

Both grades share essential toughness. Their density is extremely high. This suggests low porosity. Fluids and gases battle to penetrate. They stand up to chemical strikes well. Acids and antacid cause little damage. Thermal shock resistance is another plus. They deal with unexpected temperature swings without splitting. This is crucial in procedures with quick heating or cooling down cycles.

These ceramic blocks are incredibly difficult. Their hardness competitors many metals. This equates straight to long life. They outlast softer products dramatically. Abrasion and disintegration trigger very little loss. Replacement regularity drops. This saves downtime and cash.

You discover them almost everywhere warmth and use dominate. They line industrial heating systems and kilns completely. They protect delicate parts in metal processing. They act as durable linings in bulk handling systems. They function as stable supports and setters in firing porcelains. They are crucial in power generation components. Their stability makes certain consistent process problems. This integrity is critical for quality outcome.

The product is inert. It won’t pollute your products. It satisfies stringent market sanitation standards. Its electrical insulation homes are likewise outstanding. This includes flexibility for certain electrical applications.

(99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile)

Applications of 99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile

Alumina ceramic bricks and plates come in 99% and 95% purity grades. These Al2O3 products take care of extreme warmth and difficult problems well. Industries use them for reputable performance. Heating systems and kilns need linings that withstand heats. Alumina bricks function flawlessly below. They develop protective layers inside industrial home heating systems. Chemical plants encounter destructive materials. Alumina ceramics hold up against acids and antacids. Reactors and pipelines make use of these plates for long life. Mining devices suffers from rough materials. Alumina floor tiles line chutes and receptacles. They lower put on from ore and minerals. Power generation makes use of these porcelains too. They act as heat shields in boilers and burners. Electric applications require insulation. Alumina plates supply that at heats. Semiconductor production needs tidy, steady surface areas. Alumina substrates provide that in handling tools. Burner nozzles straight fires in industrial settings. Alumina components sustain the warmth without cracking. Steel mills use these bricks in ladles and tundishes. They safeguard versus molten steel sprinkle. The 99% alumina grade matches the harshest environments. It has remarkable temperature level resistance. The 95% alumina quality provides great efficiency at lower price. Both types stand up to thermal shock. They don’t warp or weaken easily. This saves cash on replacements. Alumina ceramic blocks meshed securely. They develop smooth refractory wall surfaces. Installation is simple. Maintenance stays very little. These porcelains support effectiveness in hefty industry. They maintain procedures running efficiently under stress. Select alumina for requiring applications. It delivers strength and resilience.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile

99% Alumina Ceramic Bricks FAQ

What are these bricks used for?

These bricks handle extreme heat. They line furnaces, kilns, and reactors. They protect equipment in steel plants, foundries, and chemical processing. They work where regular materials melt or break down.

How hot can they get?

These alumina bricks resist very high temperatures. The 99% Al2O3 grade handles heat up to 1650°C (3000°F). The 95% grade handles slightly lower temperatures, around 1600°C (2912°F). They stay strong and stable under constant heat.

Are they hard to install?

Installation needs care. Cut the bricks precisely to fit your furnace or kiln shape. Use special refractory mortar designed for alumina. Follow the mortar maker’s instructions exactly. Proper installation prevents cracks and heat leaks.

Will they wear out quickly?

No, they last. Alumina ceramic is very hard. It resists abrasion from hot materials moving against it. It also resists chemical attack from slags and gases. This hardness means the bricks last longer than steel or fireclay in tough spots. They handle thermal cycling better too.

How do I clean them?

Cleaning is usually simple. After cooling, brush off loose dust and debris. For tougher deposits, use a non-abrasive scraper carefully. Avoid harsh impacts. Sometimes a mild solvent wipe helps. Check specific chemical compatibility if harsh chemicals were present.

(99% 95% Alumina Ceramic Bricks Al2o3 Plates Alumina Ceramic Refractory Plate Block Ceramic Tile)

REQUEST A QUOTE

RELATED PRODUCTS

XTL Sintyron White Round Block Wear Resistant High Hardness Al2o3 Alumina Ceramic Plate

Customized High Precision Al2O3 Ceramic Block Part Non-Magnetic and High Strength 95% 99% Alumina Direct From

Heat Resistance 99% Alumina Ceramic Plate Block Industrial Al2o3 Sheet

Wearable Insulating Al2O3 Ceramic Plate Sheet Block Customized Size

Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile