Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

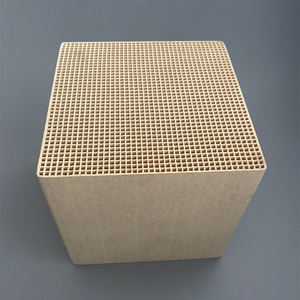

Overview of 99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate

99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of 99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate)

Specification of 99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate

This alumina ceramic block is made from 99% pure aluminum oxide (Al2O3). This high purity gives it excellent performance. We machine these blocks precisely to meet your exact size requirements. The material is incredibly hard. It resists wear exceptionally well in tough conditions. Abrasion causes minimal damage. Parts last much longer.

The ceramic has very high density. Its structure is fine and uniform. This contributes to its strength and durability. It handles extreme heat easily. You can use it continuously at temperatures over 1600°C (2912°F). It withstands sudden temperature changes well. Thermal shock resistance is very good.

Electrical insulation properties are outstanding. This is true even at very high temperatures. The surface is very smooth after machining. This minimizes friction. It resists chemical attack from many acids and alkalis. Corrosion is not a problem. It stays stable in harsh chemical environments.

These properties make it ideal for many demanding jobs. Use it for wear plates and liners in heavy machinery. It protects equipment from abrasion. It works well as heat-resistant baffles and setters in kilns and furnaces. Insulating components in high-voltage or high-temperature electrical systems are common uses. Precision fixtures and jigs benefit from its stability and hardness. You find it in semiconductor processing equipment. Chemical processing plants use it for parts exposed to corrosive materials. It serves reliably as bearing components where lubrication is difficult.

(99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate)

Applications of 99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate

Machined 99% Al₂O₃ ceramic blocks offer superior performance in tough settings. Their extreme hardness resists abrasion and wear exceptionally well. This makes them perfect for parts constantly rubbing against abrasive materials. These alumina plates handle intense heat without breaking down. They maintain strength and shape at temperatures far beyond what metals tolerate. This thermal stability is vital for furnace linings, kiln furniture, and burner nozzles.

Chemical resistance is another major benefit. These ceramic plates won’t corrode when exposed to harsh acids, alkalis, or solvents. They work reliably in chemical processing equipment, pump seals, and valve components. Electrical insulation properties are excellent. Alumina plates isolate electrical components effectively, even at high voltages and temperatures. They are common substrates in electronics and high-power applications.

Precision machining allows complex shapes. Manufacturers can create tight-tolerance blocks and plates for exacting assemblies. This includes fixtures in semiconductor manufacturing or guides in textile machinery. The material’s durability means long service life. Equipment downtime for part replacement is significantly reduced. This saves money over time. High-purity alumina is biocompatible. It finds uses in demanding medical devices requiring sterility and wear resistance.

These ceramic parts are essential in semiconductor wafer processing equipment. They endure corrosive plasmas and high heat cycles. Cutting tools and wear plates in mining operations benefit from their toughness. Aerospace applications use them for heat shields and sensor components. Alumina plates line chutes handling abrasive minerals. They protect surfaces in demanding industrial environments.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate

What is alumina ceramic? Alumina ceramic is a technical material made primarily from aluminum oxide. It’s known for its exceptional hardness and chemical stability. This makes it suitable for demanding industrial environments. Our product uses 99% pure Al2O3. This high purity level delivers superior performance.

Why choose 99% Al2O3 purity? Higher purity means better material properties. 99% alumina offers greater hardness than lower grades. It provides improved wear resistance. Its strength is significantly higher too. These qualities are vital for long-lasting parts under stress. Lower purity ceramics wear out faster.

How does it resist wear? Alumina ceramic is extremely hard, nearly as hard as diamond. Hard materials resist abrasion very effectively. Surfaces sliding against it cause minimal damage. Particles or debris cannot easily scratch or erode it. This hardness is key to its durability in abrasive conditions.

What temperatures can it handle? This alumina ceramic withstands very high heat. It operates reliably up to 1650°C (about 3000°F). It doesn’t melt or deform at these temperatures. Its strength remains stable under thermal stress. This makes it perfect for furnaces, kilns, and high-heat machinery.

Where is this ceramic plate typically used? You find it in many tough industrial jobs. It lines equipment handling abrasive powders or slurries. It acts as wear plates in machinery. It serves as heat shields and insulators. Common uses include pump seals, cutting tools, and electronic substrates needing insulation.

(99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Al2o3 99% Alumina Ceramic Block Brick 25*50*10mm

Factory Supply Low 99%Al2O3 Parts Alumina Block Insulating Ceramic Socket

Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

High Temperature Wear Resistant Al2O3 99% Alumina Ceramic Solid Plate Brick Block

Customized Al2O3 Ceramic Terminal Blocks 99.5% Alumina Ceramic Precision Parts for Industrial Use Include Welding Cutting