Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

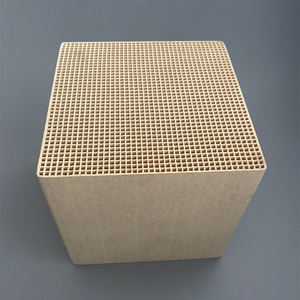

Overview of Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick

Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick)

Specification of Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick

This material is high-purity alumina ceramic. It contains 99% aluminum oxide (Al2O3). We make it using hot pressing. Hot pressing gives it excellent density. This density translates to superior hardness. The hardness is near the top for alumina ceramics. This hardness provides outstanding wear resistance. Parts last longer in abrasive conditions. This material also offers good machinability. You can machine it precisely using diamond tools. This combination is special. Very hard ceramics are often difficult to machine. This one allows both. It maintains dimensional stability under stress. It handles high temperatures well. Its maximum use temperature is around 1650°C. It resists thermal shock effectively. This ceramic is a strong electrical insulator. It has low electrical conductivity even at high temperatures. Its dielectric strength is high. It performs reliably in demanding electrical applications. The material shows good chemical resistance. It withstands attack from many acids and alkalis. It is inert in most environments. This makes it suitable for corrosive settings. Surface finish quality is achievable. You can get smooth, precise surfaces after machining. This block form is versatile. You can fabricate many custom components from it. Common applications include industrial wear parts. It is used for precision shafts and bearings. Seals and valves benefit from its properties. Cutting tools and insulators utilize this material. Semiconductor processing equipment often needs it. It serves well in high-temperature furnace fixtures. Its reliability in tough conditions is proven.

(Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick)

Applications of Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick

This alumina ceramic block is made from 99% pure aluminum oxide. It gets pressed under high heat and pressure. This process makes it incredibly hard and dense. These blocks resist wear extremely well. They also handle extreme heat and harsh chemicals easily. These properties make them essential across many demanding industries.

Semiconductor manufacturing relies heavily on these blocks. They form critical parts inside wafer processing equipment. They hold silicon wafers securely. They guide precise movements. They shield sensitive components. Their purity prevents contamination. Their stability ensures consistent, high-yield production.

Metalworking uses these blocks extensively. They form wear plates and liners inside machinery. They protect areas exposed to constant friction. They line chutes guiding abrasive materials. They serve as robust guides for wires and cables. They last much longer than metal parts in these tough jobs.

Industrial furnaces need components that survive intense heat. These alumina blocks are perfect. They form furnace linings effectively. They create sturdy setters and supports for firing ceramics or metals. They maintain their shape and strength at temperatures where metals fail.

Precision cutting tools benefit from this material. It gets used for specialized nozzles. These nozzles direct high-pressure water or abrasive particles. They withstand the constant impact and erosion. They provide reliable, long-lasting performance.

Specialized machinery often incorporates these blocks. They become durable bearings and bushings. They slide smoothly under heavy loads. They resist seizing even without constant lubrication. They work well in environments where oil or grease isn’t possible.

Medical device manufacturing uses this high-purity alumina. It creates parts requiring extreme biocompatibility. It forms components for analytical instruments demanding chemical inertness. Aerospace applications value its strength-to-weight ratio and thermal stability. It performs reliably in critical systems.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick

Here are five common questions about our Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick:

How hard is this ceramic? This material is extremely hard. It ranks just below diamond on the hardness scale. It offers exceptional resistance to wear. This makes it perfect for tough jobs. It withstands abrasion very well.

Can this ceramic be machined easily? Yes, it can be machined. It’s designed for easier machining compared to standard alumina. Precision grinding or diamond tooling works best. You need the right tools. It allows for creating complex shapes. This is a key advantage.

What temperatures can it handle? This ceramic handles very high heat. It works reliably up to 1650°C (3000°F). Its thermal stability is excellent. Sudden temperature changes won’t easily crack it. This suits furnace parts and high-heat environments.

Is it resistant to chemicals? Yes, it resists chemicals very well. Acids and alkalis don’t easily attack it. Strong solvents also cause little damage. This stability is crucial for chemical processing equipment. It prevents corrosion effectively.

How good is the surface finish? Hot pressing creates a very fine surface. It’s dense and smooth right after production. This minimizes porosity. Fewer pores mean less contamination risk. It also boosts strength. Machining can achieve even finer finishes as needed.

(Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick)

REQUEST A QUOTE

RELATED PRODUCTS

99% Al2O3 0-1mm Bauxite Ore White Fused Alumina for Ceramic Industry Raw Materials From Aluminium & SiO2 Block & Brick Patterns

Polished Al2O3 Ceramic Plate Alumina Square Block

High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications

Wearable Insulating Al2O3 Ceramic Plate Sheet Block Customized Size

Al2O3 Alumina High Precision Wear and Corrosion Resistance Ceramic Block Brick Tile