Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

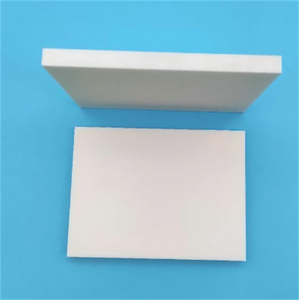

Overview of Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic)

Specification of Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

These customized alumina ceramic components deal with extreme heat. They are made from 99% pure Al2O3. This material withstands temperatures approximately 1700 ° C. Parts keep their toughness and form under these conditions. You need components for really warm atmospheres. These porcelains are a solid choice.

We maker these ceramics exactly. We create blocks, plates, tubes, and complex forms. Tell us your exact requirements. We produce parts to your details drawings. This is crucial for special applications. Get the specific geometry you require.

These components use outstanding electrical insulation. They work well in high-voltage situations. Heat doesn’t compromise their protecting capability. This is essential for electrical systems in heaters or various other hot locations.

The product is chemically inert. It stands up to attack from several acids and antacids. Harsh chemicals won’t quickly harm it. This includes in its toughness in difficult settings.

Alumina ceramic is extremely hard. It resists wear and abrasion successfully. Components last longer in abrasive conditions. This reduces replacement frequency and price.

These porcelains are excellent for requiring applications. Use them in heater cellular linings, kiln furniture, and thermal handling equipment. They work in semiconductor manufacturing devices. They offer in aerospace elements and research laboratory tools. Any kind of place needing warmth resistance, insulation, and stability benefits.

Our process focuses on custom services. We make use of premium 99% alumina powder. We shape and sinter it thoroughly. Then we equipment the sintered ceramic precisely. This attains tight tolerances and smooth finishes. Surface grinding or polishing is readily available. We satisfy your certain surface area high quality requirements.

We understand trustworthy high-temperature elements matter. Our custom alumina ceramic parts supply consistent performance. They stand up to serious thermal stress. They offer lengthy service life. Ask for a quote for your job details. We supply the precise high-heat resistant components you call for.

(Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic)

Applications of Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

Personalized high warm immune alumina ceramics architectural parts resolve challenging issues. Alumina ceramic (Al2O3) takes care of severe temperature levels conveniently. It remains strong and maintains its shape when things obtain really warm. This makes it ideal for requiring work. The 99% purity grade offers top efficiency. These parts withstand wear remarkably well. They additionally deal with chemical strikes without damages. Custom-made machining produces precise blocks and complicated shapes. You obtain components made exactly for your devices.

Semiconductor producing uses these porcelains greatly. They develop important components inside wafer handling tools. Alumina parts deal with destructive gases and plasma. They endure the high warmth inside chambers. Accuracy is non-negotiable right here. Personalized obstructs ensure excellent alignment and feature.

Industrial furnaces and kilns rely on alumina components. They function as liners, setters, and support beams. These components withstand consistent heats. They resist thermal shock from quick home heating and cooling cycles. Alumina lasts much longer than metal below. This minimizes downtime and maintenance costs significantly.

Aerospace and defense applications require integrity. Alumina ceramic parts go into sensors, insulators, and engine parts. They take care of intense heat from jet engines or rocket exhaust. Their lightweight helps improve gas performance. Electrical insulation buildings are vital in these systems.

Medical gadgets take advantage of alumina’s biocompatibility. It functions well inside sanitation tools. Autoclaves make use of custom-made alumina trays and supports. The product makes it through repeated high-pressure heavy steam cycles. It does not deteriorate or release hazardous materials.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

What is alumina ceramic? Why use it for high heat?

Alumina ceramic is mostly aluminum oxide. It handles extreme temperatures well. Other materials might crack or warp under heat. Alumina stays strong. That’s why it’s good for hot environments.

Can you make custom shapes?

Yes. We machine alumina into exact shapes you need. Simple blocks, complex parts, we can do it. Tell us your design. We make it from solid alumina ceramic material.

How hot can it get before failing?

This 99% alumina handles very high heat. It works fine long-term over 1500°C. It can handle short bursts even hotter. It won’t melt or degrade like metals or plastics can. It keeps its shape and strength.

Is precise machining possible?

Yes. We use special tools to cut alumina accurately. We control dimensions tightly. We achieve smooth finishes. Complex features like holes, slots, threads are no problem. We make parts fit your assembly perfectly.

Where are these parts typically used?

They go into very hot places. Furnace linings, kiln furniture, semiconductor processing tools, thermal insulation parts. Any equipment needing strong, stable parts in extreme heat uses alumina ceramic components.

(Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Al2O3 Ceramic Mechanical Parts Wear Resisting Ivory White Alumina Ceramic Blocks

Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick

More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

Aluminum Oxide Ceramic Board Polished 99.7% Alumina Ceramic Sheet Al2O3 Plate Ceramic Block

High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick