Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

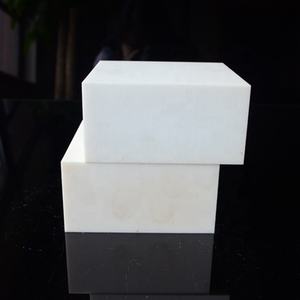

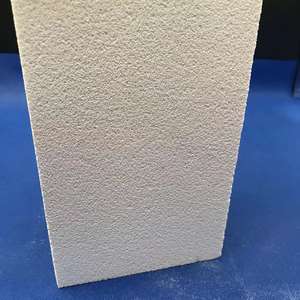

Overview of Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block)

Specification of Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

Alumina ceramic parts offer real advantages. Al2O3 is the core material. This ceramic is very hard. It resists wear extremely well. It handles high heat easily. Chemical attack doesn’t bother it much. These properties make it reliable. It lasts a long time in tough spots. You need parts with specific shapes sometimes. Standard blocks won’t always fit. That’s where customization matters. We make unique ceramic blocks. We shape them precisely to your drawings. Complex geometries are possible. We use advanced forming methods. Slip casting, injection molding, pressing – we pick the best way for your design. Precision machining comes next. We grind and cut the fired ceramic carefully. We achieve tight tolerances. Your part fits perfectly into its place. Surface finish is important too. We can make it very smooth. We can leave it rougher if needed. The ceramic stays strong throughout. It keeps its key properties after shaping. This strength is vital for demanding jobs. Think about industrial settings. These custom blocks go into many machines. They work well as wear plates. They guide materials in harsh lines. They act as strong insulators. Furnace parts need this heat resistance. Electrical components use its insulation. Chemical pumps need its corrosion shield. Every custom piece solves a specific problem. It fills a gap where metal or plastic fails. Your unique requirement drives the design. We turn that need into a real ceramic part. It performs under pressure.

(Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block)

Applications of Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

Alumina ceramic parts are special. They are made from aluminum oxide. This material is very hard. It resists wear extremely well. These ceramic parts handle high heat easily. They work fine in tough conditions. Alumina ceramic also insulates electricity very effectively. It does not conduct current. Chemical resistance is another big plus. Acids and bases don’t damage it easily. This makes Alumina parts very reliable. They last a long time in difficult places.

Getting the exact shape you need matters. Standard blocks often don’t fit perfectly. Customizable shapes solve this problem. We can make Alumina parts to your specific drawing. Unique dimensions are no problem. Complex geometries are achievable. This custom approach ensures a perfect fit for your machine. It improves performance directly. It eliminates the need for extra machining later. That saves time and money.

These custom Al2O3 blocks work in many industries. They are essential in electronics. They hold components securely. They insulate high-power systems safely. Semiconductor manufacturing relies on them heavily. Furnace linings use alumina blocks. They withstand extreme temperatures without failing. Wear parts in machinery benefit greatly. Custom alumina pieces resist abrasion far better than metal. Chemical processing equipment needs them. They handle corrosive materials reliably. Medical devices use biocompatible alumina parts. Precision instruments utilize their stability. Everywhere precise, tough, heat-resistant parts are needed, custom alumina ceramic delivers.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

What can you customize?

We make many shapes and sizes. Tell us your exact needs. We handle complex designs. Holes, grooves, special angles are possible. Send your drawing. We see if we can make it.

How precise are your parts?

Our parts are very accurate. We control dimensions tightly. Tolerances often reach +/- 0.1mm. Surface finish is very smooth. This precision is important for good fit and function. We use advanced grinding and machining.

Why pick alumina ceramic?

Alumina (Al2O3) is super hard. It resists wear extremely well. It handles heat very effectively. It insulates electricity perfectly. It fights chemicals strongly. This makes it ideal for tough industrial jobs. It lasts longer than many metals or plastics.

How do you ensure quality?

We test every batch. We check material density and purity. We measure dimensions carefully. We inspect surfaces for flaws. We do strength tests. We provide reports showing it meets standards. Quality is our main focus.

How long does production take?

Lead time depends on the order. Simple shapes take less time. Complex designs take more. Volume also affects timing. We give a clear estimate after seeing your requirements. Standard orders often finish in 2-4 weeks. We communicate any delays early.

(Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block)

REQUEST A QUOTE

RELATED PRODUCTS

Manufacturing Dry Pressing Moulding 99% Al2O3 Alumina Ceramic Block Plate

High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block

Heat Resistance 99% Alumina Ceramic Plate Block Industrial Al2o3 Sheet

High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate