Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

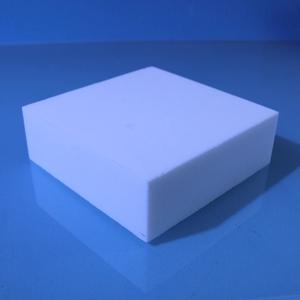

Overview of Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate

Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate)

Specification of Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate

Custom-made dimension high temperature resistant alumina ceramic components use real services for demanding heater applications. Choose from 99%, 96%, or 95% Al2O3 pureness levels. Each pureness level balances performance with price. Greater purity suggests better efficiency in severe conditions. It likewise indicates a greater rate factor. Select the most effective choice for your particular furnace atmosphere and budget.

These parts take care of extreme heat well. They resist temperatures much past what steels can endure. This capacity stops warping and melting. It guarantees secure procedure inside hot zones. The material offers excellent thermal shock resistance as well. Parts will not crack quickly throughout quick temperature swings. This integrity is vital for heater long life.

We make these elements in many shapes. Ceramic tiles, blocks, plates, and intricate geometries are standard alternatives. Inform us the specific dimensions you need. We make to your specific requirements. Perfect fit is important. It stays clear of spaces and inefficiencies in heating system cellular linings. Custom sizes mean much less waste product. You obtain parts developed for your tools, not generic shapes.

Alumina ceramic is inherently hard and long lasting. It stands up to wear from abrasion extremely efficiently. This hardness prolongs the service life considerably. Components last much longer than steel alternatives. Chemical resistance is one more significant benefit. Alumina holds up against attack from several harsh gases and liquified materials. It won’t deteriorate conveniently in extreme furnace environments. This stability protects your process and product top quality.

These residential properties make alumina ceramic ideal for critical heating system areas. Utilize these ceramic tiles, obstructs, or plates as linings, setters, supports, and baffles. They shield heating system structures from intense warm. They develop stable surfaces for processing materials. They aid keep regular temperature level profiles.

(Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate)

Applications of Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate

Customized size high temperature resistant alumina ceramic components fix challenging heating system issues. These Al2O3 components take care of extreme warm accurately. Select from 95%, 96%, or 99% purity qualities. Each grade provides particular benefits for various demands. Greater pureness normally implies much better efficiency under extreme problems. These porcelains endure temperature levels far past many metals. They withstand thermal shock well. Abrupt temperature level changes create less fracturing. This sturdiness is important inside heating systems.

Usual applications include heater cellular linings, kiln furniture, and heater parts. They function well as thermal barrier, baffles, and setters. These ceramic tiles, obstructs, and plates protect delicate heater locations. They sustain heavy lots at high warmth. The material resists chemical attack from liquified products or rough gases. This stops contamination. It likewise extends component life significantly. Much less downtime conserves money. Substitute prices reduce as well.

Personalized sizing is a significant benefit. Exactly shaped components fit intricate heater creates perfectly. This eliminates gaps. It enhances overall thermal performance. Better insulation reduces energy expenses. Personalized shapes additionally make sure even heat circulation. This causes more regular handling outcomes. Production high quality boosts. Standard sizes often need adjustment on-site. Personalized components get here prepared to mount. This quickens furnace maintenance or building and construction.

The smooth surface of alumina ceramic stands up to build-up. Slag, glass, or metal drips don’t stick conveniently. Cleansing is simpler. Maintenance periods get longer. Operators conserve time. The material’s hardness stands up to wear from rough materials. It keeps its shape under lots. Structural honesty remains high cycle after cycle. This dependability is necessary for continuous industrial processes.

Alumina ceramic parts provide a practical service for demanding furnace settings. Their heat resistance, toughness, and customizability make them indispensable. They directly improve heater performance and life expectancy.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate

What are the main features of these alumina ceramic parts? These parts are made from high purity alumina. They resist extreme heat. They are strong and hard. They handle wear and corrosion well. They are good electrical insulators. They come as tiles blocks plates. They last long in tough conditions.

What temperature can these parts handle? The 99% purity parts withstand 1750°C. The 96% parts handle 1650°C. The 95% parts handle 1600°C. They stay stable in high heat. They do not melt easily. They keep their shape under stress.

Where are these parts commonly used? They go into high temperature furnaces. They work in kilns and reactors. They fit heat treatment equipment. They are in semiconductor manufacturing. They serve as linings setters insulators. They are in glass and steel industries too.

Can you make custom sizes and shapes? Yes. We cut and shape ceramics to your needs. We produce tiles blocks plates in any size. We make complex shapes if required. Tell us your requirements. We use precise machining.

What is the difference between 99% 96% 95% purity? Purity affects performance. Higher purity means better heat resistance. Higher purity gives more strength. Higher purity resists corrosion better. The 99% grade is top quality. It suits extreme conditions. The 96% and 95% grades save money. They work well in less harsh environments.

(Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block

XTL Sintyron White Round Block Wear Resistant High Hardness Al2o3 Alumina Ceramic Plate

High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

High-Purity Custom-Made Alumina Ceramic Blocks

Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block