Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

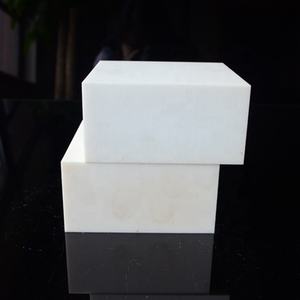

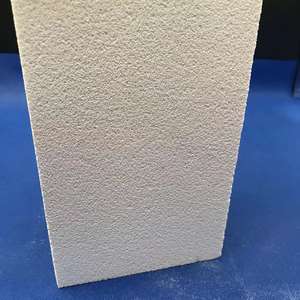

Overview of Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate

Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate)

Specification of Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate

Personalized ZTA Al Two O Three Alumina ZrO ₂ Zirconia Ceramic Refractory Bricks Blocks Plates manage extreme warm and wear. These items blend alumina and zirconia. This combination creates a strong material. It resists very heats. It likewise fights off rust and abrasion. These porcelains work well in rough commercial setups.

The material has exceptional strength. It does not split conveniently under anxiety. It manages sudden temperature adjustments. This is thermal shock resistance. The blocks obstructs plates keep their form. They last longer than common refractories. This minimizes substitute prices.

We make these items to your precise demands. You choose the dimension. You select the shape. We generate simple blocks or intricate plates. We offer different densities. We meet tight dimensional resistances. Our process makes certain consistency. We adjust make-ups for particular uses. This includes greater zirconia for durability or alumina for firmness.

These ceramics match numerous industries. They line furnaces in steel plants. They secure kilns in cement manufacturing facilities. They work in glass manufacturing. They serve in chemical handling devices. They are in power generation devices. Anywhere warmth and use reason troubles, these products assist.

The ZTA porcelains outperform typical choices. They withstand temperatures over 1600 ° C. They sustain hostile chemicals. They resist mechanical wear. This integrity means less downtime. It indicates lower maintenance expenses. It indicates far better efficiency for your procedures.

(Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate)

Applications of Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate

Personalized ZTA ceramic blocks incorporate alumina and zirconia. This mix offers excellent homes. These blocks take care of severe warmth very well. They stand up to chemical strike efficiently. Their durability is high. Thermal shock resistance is solid. This makes them essential for rough industrial settings.

Steel plants need them badly. They line furnaces and ladles. They secure essential locations. Molten metal call needs difficult materials. ZTA blocks endure this atmosphere. They last much longer than basic refractories. This lowers downtime and expense.

Glass manufacturing counts on them too. Container heaters face heats and corrosive melts. ZTA blocks develop linings here. They stand up to the aggressive glass batch materials. Regular efficiency guarantees steady production.

Chemical handling utilizes these blocks. Reactors and kilns run with corrosive materials. Acidic or fundamental problems strike weak products. ZTA porcelains use remarkable deterioration resistance. They keep stability in these challenging procedures.

Power generation take advantage of them. Boilers and incinerators create extreme heat. Gas ash and flue gases create wear. ZTA linings sustain these conditions. They offer reliable thermal insulation and protection.

Custom forms are possible. Producers cut blocks to certain dimensions. They make plates and blocks for special devices styles. Precise suitable boosts installment effectiveness. It improves overall thermal performance. Tailored remedies address complex design problems.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate

What are ZTA Al2O3/ZrO2 ceramic refractory bricks, blocks, and plates?

These are heat-resistant parts made from alumina and zirconia. They handle extreme temperatures. They are shaped into bricks, blocks, or plates. Custom sizes fit specific industrial needs.

Where are these ceramic products used?

They go into high-heat zones like furnaces, kilns, and reactors. Factories use them in steel plants, glass factories, and power stations. They shield equipment from intense heat.

Why pick ZTA Al2O3/ZrO2 over other materials?

They last longer under high heat. They resist cracking from sudden temperature changes. They endure physical wear better than basic ceramics. This saves money on replacements.

Can you make these parts in custom shapes?

Yes. Dimensions and thicknesses are adjustable. Holes, slots, or curves are possible. Tell us your requirements. We produce them to match your equipment exactly.

How do I handle these bricks and plates safely?

Wear gloves to avoid skin irritation. Store them flat on a dry surface. Install them carefully to prevent chipping. Check for cracks before use. Replace damaged pieces immediately.

(Customized ZTA Al2o3 Alumina Zro2 Zirconia Ceramic Refractory Bricks Block Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

Heat Resistance Alumina Ceramic Sintering Plate Al2O3 Ceramic Block

High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

Customized High Precision Al2O3 Ceramic Block Part Non-Magnetic and High Strength 95% 99% Alumina Direct From