Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

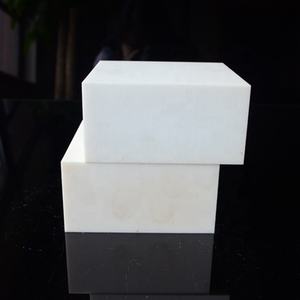

Overview of Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing

Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing)

Specification of Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing

This straight customized Al2O3 ceramic block makes use of 95% alumina. It provides high performance for difficult commercial tasks. The product is really tough. This hardness fights put on successfully. Parts last much longer under unpleasant conditions. Grinding devices profit greatly. Leading edges stay sharp. The ceramic manages high warm well. It resists thermal shock. Abrupt temperature modifications cause less splitting. Welding components require this security. Thermal management elements count on it.

We equipment these blocks exactly to your drawings. You obtain the precise form you require. Facility geometries are feasible. We manage measurements snugly. Tolerances meet requiring criteria. Surface coatings are smooth. Coatings can be tailored for specific features. Decreased rubbing is attainable. Better securing surfaces are feasible.

The high alumina content makes certain chemical inertness. Acids and alkalis create very little assault. Destructive atmospheres are less damaging. The ceramic will not easily weaken. Its electric insulation buildings are exceptional. It stops present circulation dependably. Digital applications use this feature. High-voltage scenarios require it.

This ceramic has high thickness. The structure is extremely strong. Mechanical tension is resisted well. Impact resistance is good for a ceramic. Compression toughness is specifically high. It supports heavy tons. Structural parts utilize this toughness. Put on plates exploit its longevity.

These blocks are perfect for grinding device bases. They supply secure, wear-resistant platforms. Welding jigs and fixtures utilize them for warmth resistance. Precision knife blades make use of the solidity. Reducing devices utilize the sharp side retention. Put on parts in machinery last longer. Protecting components perform dependably. Send us your specs. We create the ceramic parts you need.

(Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing)

Applications of Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing

These Direct Custom-made Al2O3 Ceramic Blocks offer difficult services for requiring industrial jobs. They are made from 95% Alumina Porcelain. This product gives them extraordinary properties. Their hardness is extremely high. This solidity makes them withstand put on exceptionally well. Components last much longer than steel options. Unpleasant materials trigger much less damages. This is crucial for grinding procedures. They hold up against consistent rubbing. Grinding wheels and linings benefit considerably. Tool life enhances considerably.

Warm resistance is one more major advantage. These ceramic parts take care of really high temperatures. They preserve their toughness. This makes them excellent for welding applications. They serve efficiently as welding components. They act as dependable warmth obstacles. They place warm elements safely. Weld quality stays consistent. The ceramic does not warp or break down under extreme warm.

Chemical stability is vital. The 95% Alumina Porcelain resists numerous rough chemicals. It doesn’t rust quickly. This shields parts in aggressive environments. Grinding fluids or other chemicals present less threat. Long-lasting reliability rises.

Modification is main to their worth. Producers create blocks specifically to your drawings. They match precise dimensions. They satisfy particular opening placements. They fit intricate surface contours. This makes certain an excellent suitable for your machinery. It enhances performance in knife processing jigs. It improves accuracy in grinding components. It secures parts completely for welding. Off-the-shelf components usually trigger problems. Customized obstructs remove these concerns.

Knife handling depends on precision and security. These ceramic blocks give a solid, non-marring base. They hold cutting tools firmly. They assist blades precisely. They protect against slippage throughout developing or machining. Surface finish top quality boosts. Manufacturing consistency improves.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing

(Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing)

REQUEST A QUOTE

RELATED PRODUCTS

Customized High Precision Al2O3 Ceramic Block Part Non-Magnetic and High Strength 95% 99% Alumina Direct From

Aluminum Oxide Ceramic Board Polished 99.7% Alumina Ceramic Sheet Al2O3 Plate Ceramic Block

High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

High Temperature 1500 Ceramic Plate Alumina Square Block Polished Porous Al2O3 for Industrial Use Customizable Cutting Service