Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

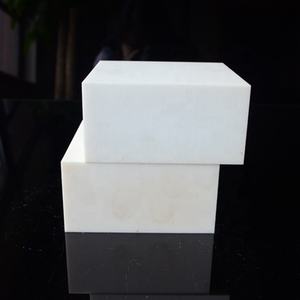

Overview of Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block

Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block )

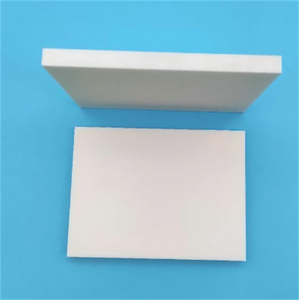

Specification of Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block

These alumina ceramic blocks supply exceptional heat and wear resistance. They contain over 96% pure light weight aluminum oxide (Al2O3). This high pureness makes them exceptionally hard. They endure severe abrasion and continuous friction very well.

The blocks manage severe temperatures quickly. They run reliably up to 1600 degrees Celsius. They handle sudden temperature level adjustments properly. This thermal shock resistance stops cracking. Their thick structure reduces porosity. This thickness improves mechanical toughness considerably. It additionally enhances chemical security. The blocks withstand attack from many acids and alkalis. They are untouched by the majority of destructive gases.

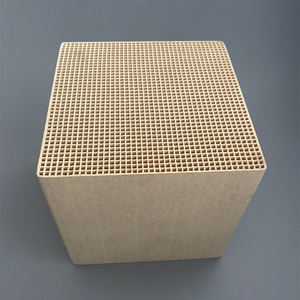

These residential properties make the blocks perfect for demanding work. Utilize them as wear-resistant linings in heavy equipment. Mount them in chutes, hoppers, and cyclones. They shield surfaces in mining and product handling. They are perfect for high-temperature heating system components. Utilize them for kiln furnishings like setters and plates. They work well as heat shields and heater nozzles. Their electric insulation is excellent. They offer dependably in electric applications requiring seclusion.

The blocks use a long life span. They decrease upkeep downtime. They reduced substitute expenses substantially. Their consistent performance is reliable. Industries needing hard products choose them. This includes mining, ceramics, power generation, and chemical processing. They supply a robust remedy versus rough problems.

(Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block )

Applications of Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block

Alumina ceramic blocks supply superior efficiency in challenging problems. These blocks manage extreme warmth well. They withstand use boldy. This makes them crucial throughout demanding industries. Steel processing plants utilize them as kiln furniture. They support heavy lots during shooting. They make it through repeated thermal cycling. Chemical centers line activators with them. They secure versus corrosive products. They endure high-pressure reactions. Mining operations install them in transfer chutes. They protect surface areas from rough ores. They last a lot longer than steel. Power generation plants utilize them in cyclone separators. They catch fly ash successfully. They stand up to constant particle bombardment. Manufacturing counts on them for nozzles and overviews. They guide rough products specifically. They maintain shape under rubbing. These blocks operate in heating system linings too. They shield properly. They stop warm loss. Their firmness fights erosion regularly. They operate accurately at heats. Lots of industries choose them for critical wear zones. They reduce devices downtime substantially. They reduced substitute expenses. Their security under thermal shock is proven. They use a trustworthy solution for harsh atmospheres.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block

Here are five common questions about our high-temperature wear-resistant alumina ceramic blocks:

What material makes these blocks so tough? These blocks are made from high-purity alumina (Al2O3). The alumina content is very high, usually over 92%. This high purity gives them exceptional hardness. They are much harder than steel. This hardness directly fights wear.

How hot can these ceramic blocks get? These alumina blocks handle extreme heat very well. They work reliably in environments exceeding 1600°C (2912°F). They resist thermal shock too. Sudden temperature changes won’t easily crack them. This makes them stable in hot, fluctuating conditions.

Why are they good against wear? Their extreme hardness is the main reason. Hard materials resist abrasion better. Abrasive particles scraping the surface cause less damage. The blocks also have a very dense structure. This density comes from the sintering process. Dense material stops particles from gouging deep grooves.

Where are these blocks typically used? They are essential in heavy industries facing high heat and abrasion. You find them lining equipment in power plants burning coal or biomass. They protect parts in cement and steel mills. Mining equipment handling abrasive ores uses them. Any place needing protection from hot, scouring materials uses these blocks.

How do you install these ceramic blocks? Installation is straightforward. The blocks usually have pre-formed holes or shapes. Metal anchors or bolts secure them directly onto the equipment’s steel shell. A high-temperature adhesive paste often provides extra bonding strength. This ensures the blocks stay firmly in place during operation.

(Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block )

REQUEST A QUOTE

RELATED PRODUCTS

Customized Al2O3 High Hardness High Pure Ceramic Piece Alumina Ceramic Alumina Ceramic Washer Terminal Blocks for CNC Machining

Heat Resistance 99% Alumina Ceramic Plate Block Industrial Al2o3 Sheet

Customized High Precision Al2O3 Ceramic Block Part Non-Magnetic and High Strength 95% 99% Alumina Direct From

Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications