Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

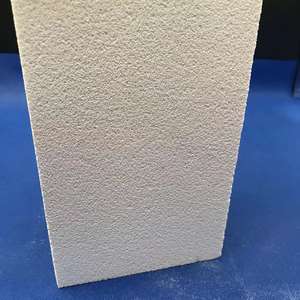

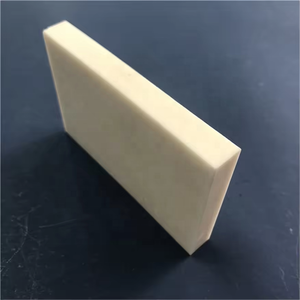

Overview of High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate)

Specification of High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

This alumina ceramic plate provides exceptional performance. It includes 99% light weight aluminum oxide. This high pureness issues. It gives the material its special high qualities. You need strong wear resistance. This plate provides. It manages rough conditions effectively. Components last much longer. Downtime decreases. Upkeep prices decrease.

Electric insulation is vital for numerous usages. This plate blocks electrical power effectively. It keeps high voltages securely contained. You avoid brief circuits. You prevent equipment damages. Workers remain risk-free. The dielectric stamina is high. It carries out accurately under electric stress.

Heat doesn’t bother this ceramic much. It holds up against heats without transforming form or weakening. Thermal shock resistance is good. Abrupt temperature shifts trigger fewer troubles. The product stays steady. Performance stays consistent.

The surface area is really difficult. Firmness approaches that of rubies. Abrasive materials create minimal wear. Surfaces remain smooth longer. Rubbing stays low. This hardness likewise suggests excellent mechanical stamina. The plate stands up to damaging under stress. It handles heavy loads reliably.

Chemical stability is another plus. Acids and antacids have little result. Harsh industrial settings present less risk. The material does not wear away quickly. Lasting reliability boosts.

This alumina plate works well for numerous tasks. Use it for circuit bases requiring insulation and warmth control. Use it as wear plates in challenging machinery. Use it for insulating parts in high-voltage equipment. Use it for sensor housings calling for longevity and electrical isolation. Its dimensional precision is precise. Machining to tight specifications is feasible. Custom shapes are attainable.

(High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate)

Applications of High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

This alumina ceramic material is unbelievably hard. It withstands deterioration exceptionally well. This strength makes it excellent for requiring scenarios where surfaces rub together continuously. Assume heavy equipment parts that experience constant friction. It holds up much longer than softer products.

The product is 99% pure aluminum oxide. This high pureness gives it exceptional electric insulation. It blocks power reliably, also under high voltage. You locate it inside electric components needing safety and long life.

Its combination of firmness and insulation is important. It works well in spark plug insulators. These deal with intense warmth and electrical stress inside engines. The alumina protects against electric shorts and holds up against the severe atmosphere.

Circuit boards utilize it for important insulating layers. These layers separate conductive paths reliably. The product’s resistance to abrasion shields the fragile circuits during production and usage.

Commercial devices advantages considerably. Use plates made from this alumina line chutes and hoppers taking care of unpleasant products like sand or crushed rock. They last much longer than steel plates, reducing downtime and substitute costs. Bearings and seals in challenging settings utilize it too. It deals with high stress and rubbing without failing.

Sensor parts usually use this ceramic. It shields delicate electronic parts from physical damages and electric interference. High-temperature heaters use it for insulating parts. It keeps its toughness and insulation residential or commercial properties even when very warm. Reducing devices sometimes make use of alumina inserts. They remain sharp cutting rough materials.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

Here are 5 FAQs about High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate:

1. How tough is this alumina ceramic against wear?

This ceramic is extremely hard. It resists scratches and surface damage much better than steel. It lasts much longer in rough, abrasive environments. This makes it ideal for parts experiencing constant friction.

2. Does it work well for electrical insulation?

Yes, it’s an excellent electrical insulator. Its high purity alumina content prevents current flow. You can rely on it for safe electrical separation in demanding applications. Its insulation holds even at high temperatures.

3. What temperatures can it handle?

This alumina ceramic withstands very high heat. It operates reliably up to 1600°C. Avoid sudden, extreme temperature changes. Thermal shock can cause cracking. Its stability is key for furnace parts and high-heat electronics.

4. Can you customize the size and shape?

Yes, we offer custom machining. We can produce specific blocks, plates, or complex geometries. Tell us your exact dimensions and tolerances. We manufacture precisely to your requirements.

5. How do you handle and install it?

Handle this ceramic carefully. It is very hard but can crack under sharp impact. Use appropriate tools for machining. Avoid dropping it or applying point loads. Ensure surfaces are clean and properly supported during installation.

(High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Wear Resistant Al2O3 99% Alumina Ceramic Solid Plate Brick Block

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Custom Ra0.2 Alumina Ceramic Part Block High Purity 99 Al2o3 Ceramic Plate Substrate Sheet -With Laser Engrave ” X ” One Side

Customized High Purity 99% 96% 99.5% 99.7% Grooved Al2O3 Alumina Ceramic Plate Block Chunk

High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick