Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

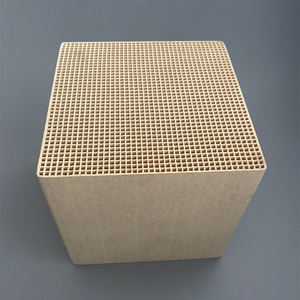

Overview of High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications

High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications)

Specification of High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications

This high pureness alumina ceramic block provides extraordinary efficiency for demanding industrial settings. Its make-up is 99% Al2O3. This assures exceptional product residential properties. The ceramic withstands intense warm remarkably well. It runs accurately up to 1650 ° C continually. It manages even greater heights briefly. Thermal shock resistance is solid. Sudden temperature level modifications cause minimal damage. This material is unbelievably hard. It measures 9 on the Mohs range. Put on resistance is excellent. Abrasion causes extremely little material loss. The block offers high mechanical strength. Compressive strength exceeds 2200 MPa. Flexural strength is robust at over 300 MPa. Electrical insulation properties are superb. This lingers even at very heats. Chemical inertness is a crucial feature. The ceramic stands up to strike from many acids and alkalis. It handles molten steels without deteriorating. Density is continually high at around 3.9 g/cm FOUR. Low porosity makes certain architectural honesty. This lessens fluid or gas penetration. Accuracy machining is achievable. The alumina block maintains limited dimensional tolerances. Surface surfaces can be really smooth. This fulfills demanding application needs. Normal dimensions are customizable. Typical sizes range from small components to larger blocks. Requirement densities usually fall in between 5mm and 50mm. Size and size vary widely based on client demands. This material suits countless harsh industrial uses. It operates well in heating system linings, kiln furnishings, and warm treatment fixtures. It serves reliably as welding nozzle suggestions and plasma torch parts. It works efficiently in semiconductor handling equipment. It does continually in chemical handling settings. It provides durable wear plates and overviews. Its stability supports precision dimension devices. This alumina ceramic block is crafted for sturdiness. It gives a reputable, resilient solution.

(High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications)

Applications of High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications

High purity alumina ceramic blocks master requiring industrial settings. This material stands up to extreme heat exceptionally well. It keeps stamina and shape at temperature levels going beyond 1600 ° C. This makes it perfect for heater linings, kiln furnishings, and heater nozzles. Components last much longer in harsh thermal cycles. Alumina ceramic offers superior hardness. It withstands wear and abrasion efficiently. This property is vital for parts like cutting tools, grinding media, and wear plates. Equipment components experience less damages in time. Surface high quality remains regular.

The material supplies exceptional electric insulation. It works reliably also at really high temperatures. This fits it for protecting parts in electronics and sensors. It protects against existing leakage effectively. Chemical resistance is one more significant advantage. Alumina ceramic resists attack from several acids and alkalis. It carries out dependably in corrosive chemical processing settings. Seals, valves, and pump parts benefit substantially. Mechanical security is crucial. Alumina blocks don’t warp or flaw under heavy tons. They supply a steady system for accuracy manufacturing equipment.

Designers utilize these blocks for specialized components and jigs. They provide dimensional security. Thermal shock resistance is impressive. Alumina ceramic takes care of abrupt temperature adjustments without breaking. This is essential for applications like warmth exchanger components and thermocouple defense tubes. The product lessens downtime. Its inert nature issues. Alumina ceramic doesn’t contaminate sensitive procedures. This is necessary in semiconductor manufacturing and pharmaceutical manufacturing. It makes certain item purity. High precision machining is attainable. Manufacturers produce complicated, tight-tolerance components from these blocks. This satisfies precise engineering specs.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications

What are these alumina ceramic blocks?

These are industrial ceramic components made from 99% pure aluminum oxide (Al2O3). This high purity gives them excellent hardness, wear resistance, and stability. They withstand severe environments. Manufacturers sinter the alumina powder at high temperatures to achieve dense blocks.

How hot can these blocks handle?

These blocks resist very high temperatures. Their maximum continuous use temperature is about 1650°C (3000°F). They handle thermal shock well. This means they cope with rapid temperature changes without cracking easily. This property is crucial for demanding industrial processes.

Why is “high precision” important?

Industrial applications often need exact dimensions. These blocks are machined after sintering to achieve tight tolerances. This precision ensures they fit correctly into machinery and systems. Accurate dimensions also guarantee consistent performance. Reliability is critical.

Where are these ceramic blocks typically used?

They serve many tough industrial roles. Common uses include furnace linings, kiln furniture, wear-resistant parts, and electrical insulators. You find them in semiconductor equipment, chemical processing plants, and high-temperature sensors. They perform where metals fail.

Are there handling precautions?

Yes. Alumina ceramic is extremely hard. This hardness makes it brittle. Avoid impacts or dropping. Handle the blocks carefully. Use appropriate tools during installation. Prevent sudden temperature changes exceeding their rated thermal shock capability. Proper handling prevents chipping or breakage.

(High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Wear Resistant Al2O3 99% Alumina Ceramic Solid Plate Brick Block

Heat Resistance Alumina Ceramic Sintering Plate Al2O3 Ceramic Block

Customized Al2O3 Ceramic Mechanical Parts Wear Resisting Ivory White Alumina Ceramic Blocks

Custom Ra0.2 Alumina Ceramic Part Block High Purity 99 Al2o3 Ceramic Plate Substrate Sheet -With Laser Engrave ” X ” One Side

Square 99% Alumina Ceramic Sheet Al2o3 Plate Block With Hole