Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

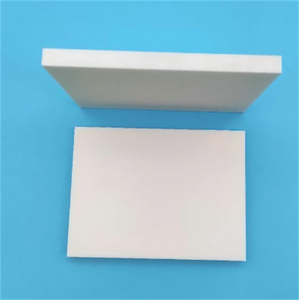

Overview of High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk

High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk)

Specification of High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk

This item is a high pureness alumina ceramic block. It consists of 99% alumina (Al2O3). This high pureness level gives superior efficiency. The product is extremely tough. It withstands wear extremely well. It takes care of extreme warm up to 1650 ° C. It also endures chemical rust. These blocks are sintered at high temperatures. This creates a thick, strong framework.

The alumina ceramic block has many industrial usages. It operates in high-temperature heating systems. It functions as kiln furniture for firing processes. Semiconductor factories utilize it for wafer handling. Chemical plants mount it as activator linings. It shields devices from severe substances. It suits wear-prone areas like chutes or seals. Its smooth surface minimizes friction.

Trick advantages include lengthy service life. This reduces substitute costs. The material stays secure under thermal anxiety. It functions as an electrical insulator. This is crucial for digital applications. Customized sizes are readily available. Manufacturers form obstructs precisely. They fit certain equipment demands. Usual types consist of blocks and pieces.

Quality control is stringent. Manufacturing decreases contaminations. The ceramic has attire thickness. It shows regular ivory-white shade. Defects are gotten rid of. Examining covers hardness and toughness. Industrial requirements are fulfilled. Various grades exist. Some focus on purity. Others concentrate on strength. Thermal shock resistance is flexible.

This alumina ceramic chunk is trusted. It does in demanding problems. Industries trust fund it for crucial applications. Designers select it for sturdiness. Upkeep needs decline considerably. Functional performance enhances.

(High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk)

Applications of High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk

High purity 99% alumina ceramic blocks are difficult blocks made almost entirely from aluminum oxide. They stand up to extreme conditions. These blocks manage very heats conveniently. They do not melt or damage much even above 1500 ° C. This makes them ideal inside furnaces and kilns. They line the warm zones. They likewise develop strong supports called kiln furnishings. These supports hold other products during shooting. The blocks resist wear exceptionally well. Their surface area stays smooth under friction. This property is important for parts like guides, linings, and chutes managing abrasive products. They last much longer than steel in these tough jobs.

The product is chemically inert. It will not react with the majority of acids or alkalis. This security is necessary in chemical processing plants. The blocks include corrosive fluids securely. They work well in rough chemical settings. Their electric insulation homes are exceptional. Alumina blocks don’t perform electrical power. They are reputable insulators in high-temperature electric systems. They separate elements effectively.

Semiconductor making demands ultra-clean, stable products. High pureness alumina blocks fit completely. They construct vital components inside wafer handling tools. They do not contaminate the sensitive atmosphere. Labs utilize these blocks too. They form accuracy surfaces for screening. They hold examples securely. The blocks give a secure, non-reactive base. Metal processing relies upon their warm resistance. They line molten metal handling locations. They safeguard tools from extreme heat and splash. These bricks are also typical in premium welding. They make long lasting nozzles and components. They endure the welding arc’s heat. The blocks are really hard. They stand up to scratching and impact much better than lots of products. This solidity safeguards surfaces and tools. Engineers select them for demanding mechanical applications. They require reliable efficiency under stress and anxiety. The product offers consistent outcomes. It carries out naturally in time.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk

What is High Purity 99% Alumina Ceramic Block? This ceramic block is made from aluminum oxide. It has 99% purity. It is very hard and strong. It handles extreme heat well. It resists chemicals and wear. These features make it last long in tough conditions.

Where is this ceramic block used? It works in high-temperature settings. Examples include kiln linings and furnace parts. It is good for semiconductor tools. It fits in laboratory equipment. It serves in electrical insulation applications. Its toughness helps in industrial machinery.

Why choose 99% purity over lower grades? Higher purity means better performance. It gives superior heat resistance. It offers stronger mechanical properties. It improves electrical insulation. It resists corrosion better. Lower purity ceramics wear out faster.

How does it compare to regular alumina blocks? Regular blocks have 92-95% purity. This 99% block is harder. It withstands higher temperatures. It lasts longer under stress. It costs more but performs better. It suits critical applications where failure isn’t an option.

How should I handle and store these blocks? Handle them gently. They are hard but can chip if dropped. Wear gloves to avoid skin oils. Store them in a dry place. Keep them away from strong acids or alkalis. Stack them carefully to prevent cracks. Check for damage before use.

(High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

Ceramic Thermal Insulation Al2o3 Alumina Ceramic Block 92 Alumina Ceramic Lining Tile Block

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Customized Al2O3 Ceramic Terminal Blocks 99.5% Alumina Ceramic Precision Parts for Industrial Use Include Welding Cutting

Heat Resistance Alumina Ceramic Sintering Plate Al2O3 Ceramic Block