Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

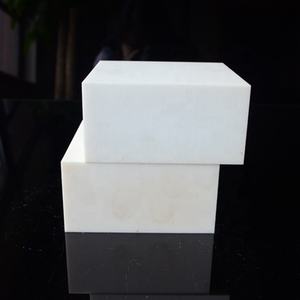

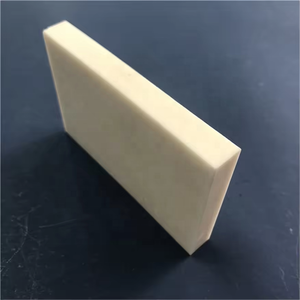

Overview of High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick)

Specification of High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

This High Purity Al2O3 Ceramic Block supplies extraordinary efficiency. It’s a square plate or block made from virtually pure aluminum oxide. The alumina content is very high, generally 99.5% or even more. This high pureness is essential. It directly influences the product’s outstanding residential or commercial properties.

The block supplies superb firmness. It withstands wear and abrasion incredibly well. This makes it ideal for hard atmospheres. Its surface area remains smooth even under hefty use. The product reveals terrific stamina. It handles high mechanical lots dependably. This structural honesty is important for requiring applications.

Thermal security is a significant benefit. The ceramic block withstands very high temperatures. It executes well up to 1700 ° C and even greater. This warmth resistance prevents warping or splitting. The material also provides fantastic electric insulation. It dependably blocks electric present also at raised temperature levels. This electrical building is critical for many uses.

Chemical inertness is an additional benefit. The block resists assault from many acids and alkalis. It doesn’t rust conveniently. This guarantees lengthy life span in extreme chemical settings. The material includes reduced porosity. Its density is extremely high. This limited structure enhances its toughness and impermeability.

Common measurements consist of different densities, widths, and sizes. Criterion dimensions are readily available. Customized dimensions can usually be created. Surface area surfaces range from basic to precision ground. This accommodates different application demands. The block is very flexible. It offers vital roles across markets.

You locate it in semiconductor production equipment. It manages wafers specifically. It’s used in high-temperature heating system linings and setters. The block provides stable, inert surface areas. It serves as wear-resistant linings in machinery. This protects against abrasion. The ceramic is vital for specific electrical insulators. It functions dependably in extreme problems. Industrial laser components use its thermal and stability buildings.

(High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick)

Applications of High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

High pureness Al2O3 ceramic blocks, plates, and blocks supply special residential properties. Individuals value them for severe hardness and exceptional wear resistance. These porcelains manage very high temperatures conveniently. They stand up to chemical strike from lots of acids and antacids. Their electric insulation buildings are excellent. This combination makes them essential popular areas.

The semiconductor sector counts heavily on these porcelains. Producers utilize them for wafer handling chucks and providers. These parts require absolute sanitation and stability. Alumina layers ensure no contamination impacts sensitive silicon wafers. They give a reputable surface area throughout etching and deposition processes.

Industrial furnaces utilize alumina bricks and obstructs thoroughly. They line high-temperature kilns and heating units. This lining withstands intense heat for extended periods. Alumina blocks protect the heating system structure. They maintain regular internal temperature levels.

Trimming devices gain from alumina’s solidity. Manufacturers bond alumina plates to device bodies. These inserts reduced abrasive materials efficiently. They last much longer than numerous metal tools. This decreases equipment downtime.

Laboratories utilize alumina plates as steady work surfaces. They are inert and hold up against rough chemicals. Scientists perform experiments directly on them. Crucibles made from alumina obstructs hold molten steels securely. They don’t respond with the melt.

Several wear parts use these porcelains. Alumina obstructs line pipelines managing unpleasant slurries. They shield pumps and valves from disintegration. Alumina layers act as birthing surfaces in equipment. They lower friction and component wear considerably.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

What exactly is this ceramic block?

It’s a solid square plate or brick made from nearly pure aluminum oxide. We call it Al2O3 ceramic. The material gets fired at extreme heat. This makes it incredibly hard and durable. High purity means over 95% aluminum oxide content. This purity is key for performance.

Why is high purity important?

Higher purity directly improves the material’s properties. It makes the ceramic much harder. It withstands wear far better. It handles chemical corrosion exceptionally well. High purity also ensures better electrical insulation. It resists higher temperatures reliably. Lower purity grades don’t perform as well.

How much heat can it take?

This alumina ceramic handles very high temperatures easily. It works fine continuously up to 1650°C (about 3000°F). It won’t melt or deform at these heats. It handles sudden temperature changes well too. This makes it perfect for furnaces and high-heat tools.

Where is this ceramic block typically used?

Its toughness and heat resistance make it very versatile. Common uses are furnace linings, kiln furniture, and heat shields. It’s essential in semiconductor processing equipment. Labs use it for high-temperature sample holders. Industry uses it for wear plates, insulators, and grinding media. It fits anywhere needing extreme durability and heat.

Is it difficult to machine or install?

Yes, machining this ceramic after firing is extremely hard. Diamond tools are necessary. It’s very brittle also. Handle it carefully to avoid chipping or cracking. We supply it in precise square plate or brick shapes. This minimizes the need for customer machining. Just install it as received. Avoid impacts during handling.

(High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick)

REQUEST A QUOTE

RELATED PRODUCTS

Polished Al2O3 Ceramic Plate Alumina Square Block

Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Custom high temperature alumina al2o3 ceramic plate block crucible pot cauldron ashtray

Square 99% Alumina Ceramic Sheet Al2o3 Plate Block With Hole